- Joined

- 8 Nov 2006

- Posts

- 1,423

Do you have a finish time, or just when it happens?

yes, christmas, I said in post 333.

Do you have a finish time, or just when it happens?

Are you going to do all 4 arms extended or have the inner 2 tucked back against the shoulders?

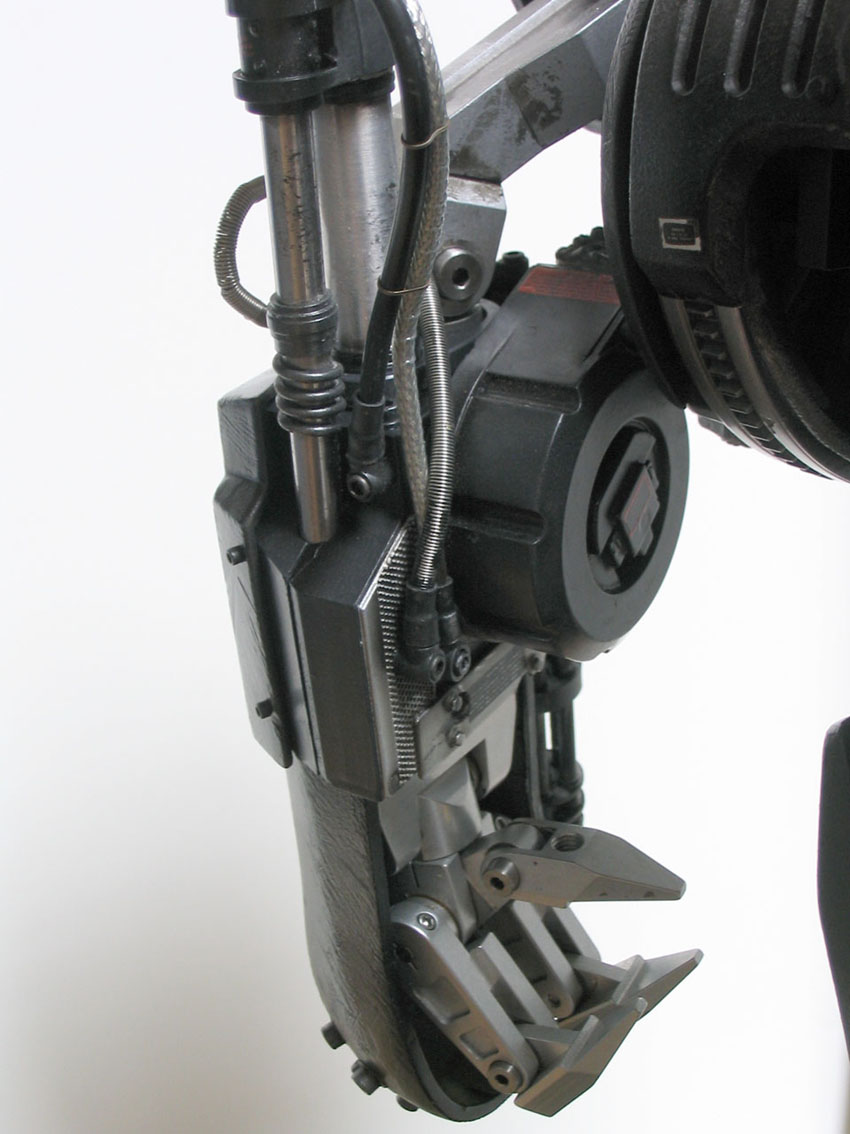

Now all it needs is a minigun

more support the better.

more support the better.The amazing work continues.That's a tiny drill bit, do they come any smaller?

Amazing! subscribed and now wanting to buy a lathe

what are u using to shape the plastic on pieces ?

epic work

I'm also looking into getting hold of a lathe after being inspired by this project. I've always wanted to have a go at making a few custom air rifle silencers. Not 100% sure a cheap lathe would do the job though, so I have a bit of reading up to do first.

I hope you don't sell it, it will be too awesome to sell

Hand crafted robot like this, seeing all the work you've put into it, I reckon it would be worth a few £k to the right person. It'll be a totally unique piece of awesomeness.

have you got pics of what you've done so far all fitted together?

or are you far off that stage yet?

i think the piece you're unsure about, this one:

http://www.ukmonsters.co.uk/robocain/DSC08965.JPG

is the mount that would allow the minigun to tilt on the Y Axis. it's either double sided (one on each side of the minigun) or single-sided, and also swivels in the X axis too

This is really looking the business mate! Have to have a proper look whenever i'm up your way next.