- Joined

- 8 Nov 2006

- Posts

- 1,423

forgot these photos yesterday

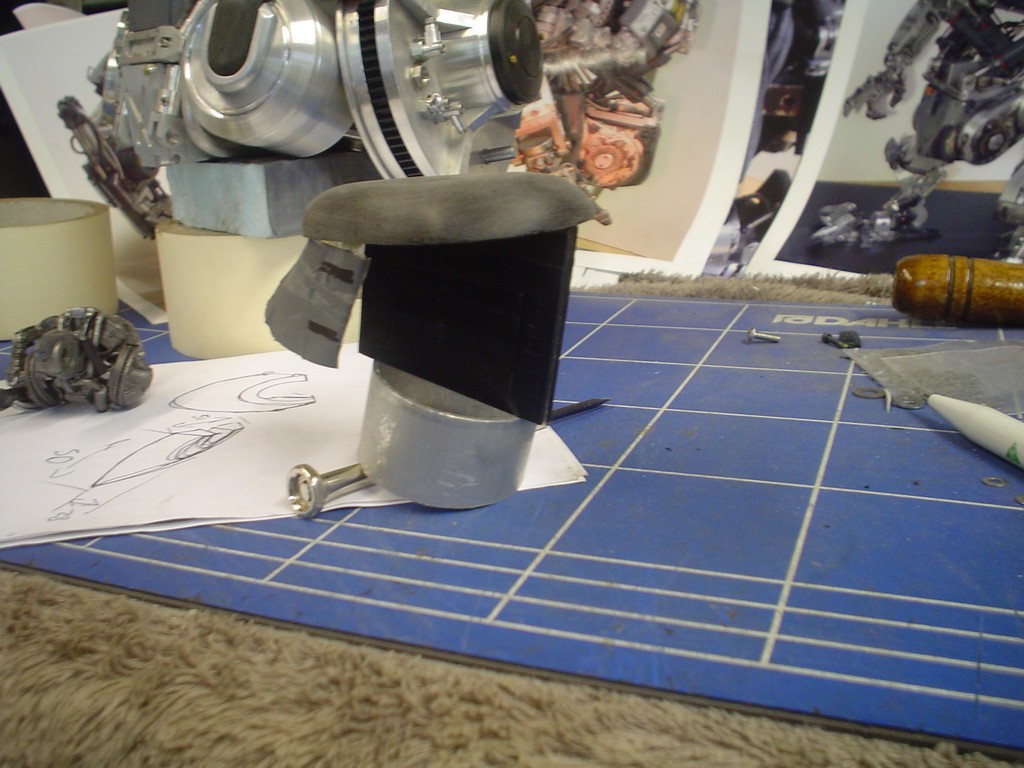

not sure if this is sloped enough

Im leaving that for a bit so I can think some more

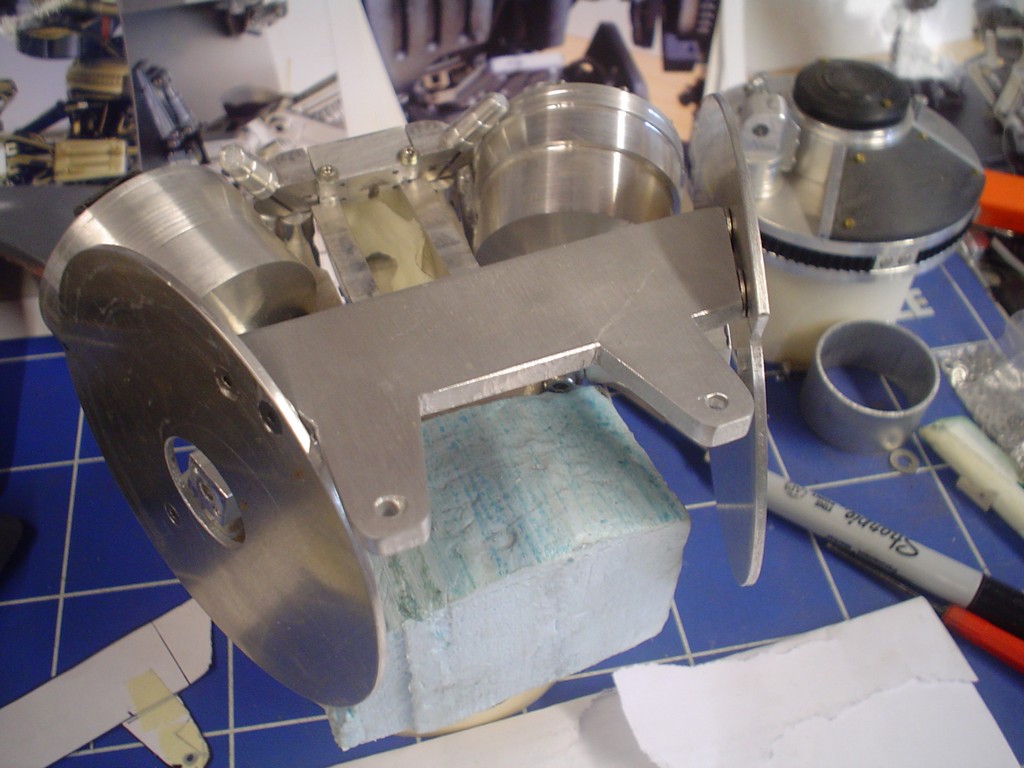

need to make a plate at the back to mount everything on

very hard to get this right, the holes at the back where the head hydraulic cylinders mount have to be ............ in the right place...... I know what im going on about.

fitted up and it clears the chest, made some U brackets

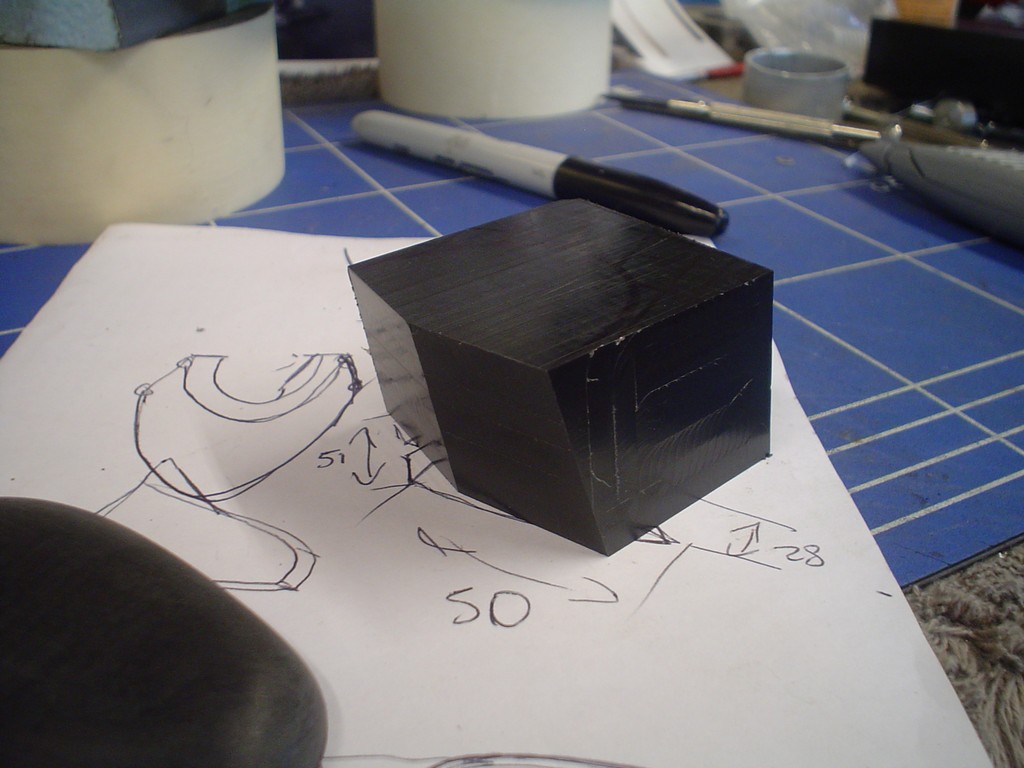

ok back to the stupid head thing, this has to cut the same each side (obviously) so it has a few degrees tilted to the side and a few tilted back at the same time, this is not easy to co-ordinate........... especially when your making it up as you go along

looks like he cut himself shaving, so the back of the head slopes to far down, need to trim that, but then....... its gonna be too short, might have to start again on this.

not sure if this is sloped enough

Im leaving that for a bit so I can think some more

need to make a plate at the back to mount everything on

very hard to get this right, the holes at the back where the head hydraulic cylinders mount have to be ............ in the right place...... I know what im going on about.

fitted up and it clears the chest, made some U brackets

ok back to the stupid head thing, this has to cut the same each side (obviously) so it has a few degrees tilted to the side and a few tilted back at the same time, this is not easy to co-ordinate........... especially when your making it up as you go along

looks like he cut himself shaving, so the back of the head slopes to far down, need to trim that, but then....... its gonna be too short, might have to start again on this.