What does this mean in practice?

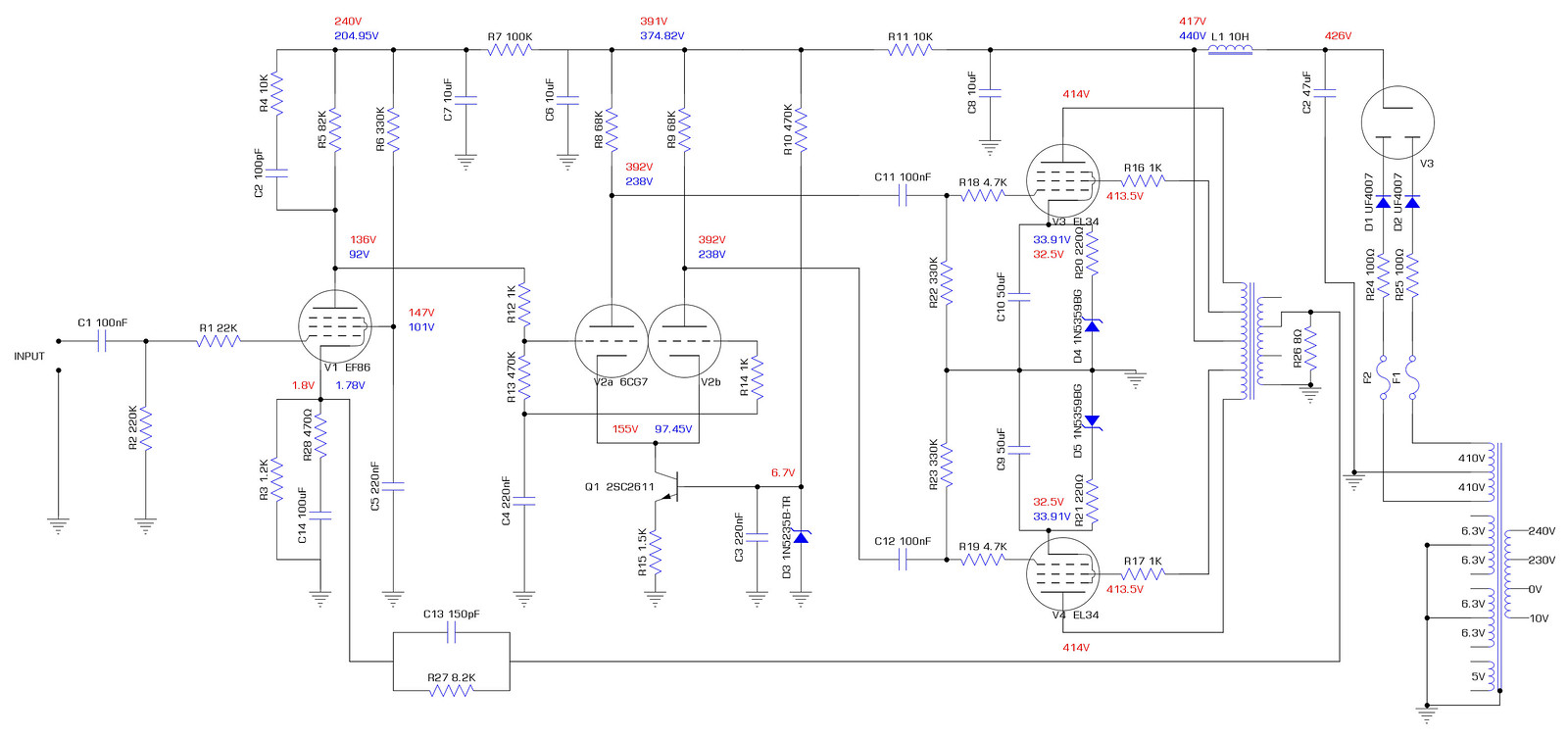

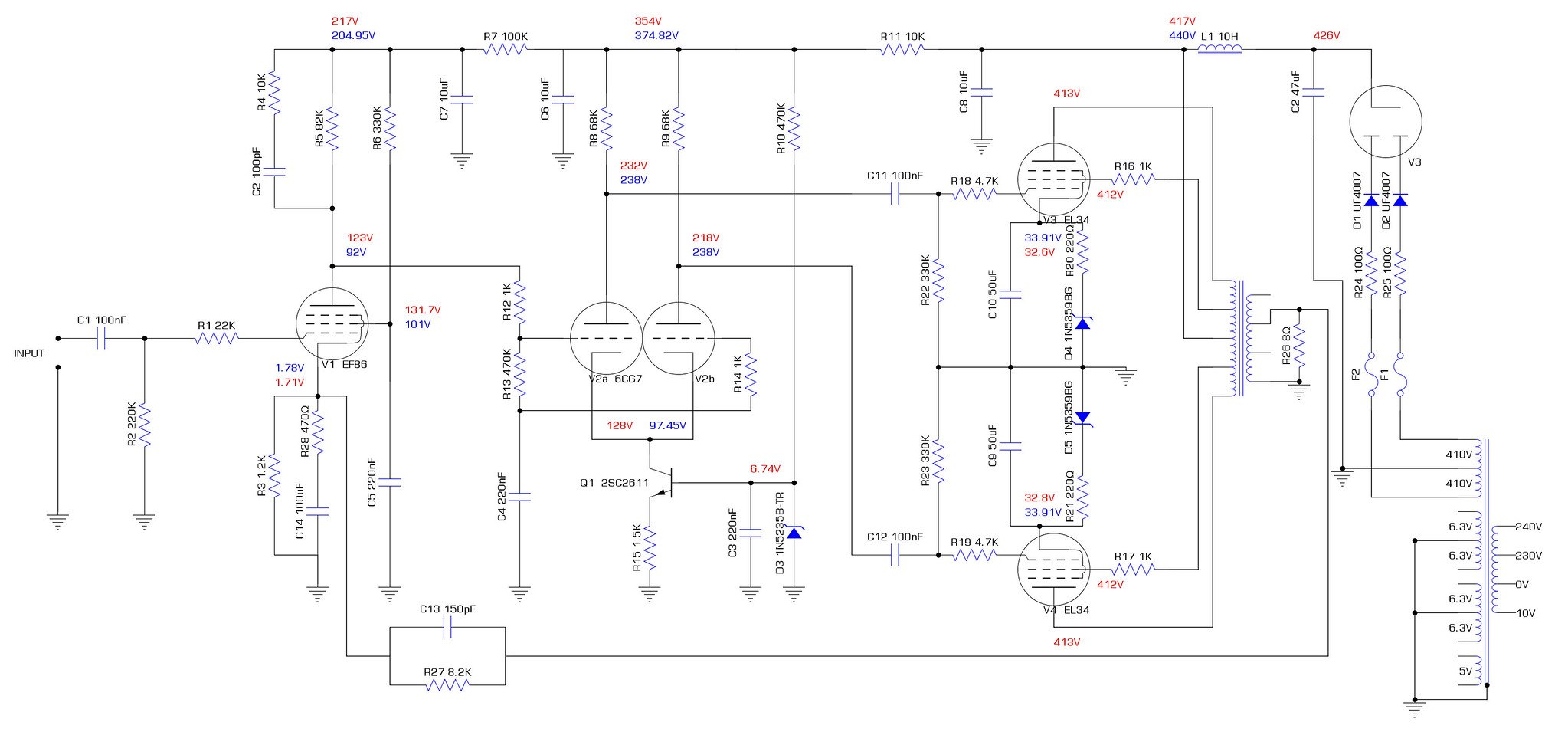

The main reason to do it is that it cancels out some of the distortion, it helps to flatten out the frequency response at the extremes and it also lowers the output impedance. I've plotted the open loop frequency response at both 1W and 20W on a graph

here. (6CG7 rebuild sheet) The frequency response falls off a cliff below 50Hz and above 10KHz. Feedback will flatten this back out to an extent. The low frequency response is affected to a certain extent by the input filtration I've applied to avoid sub sonics causing havoc.

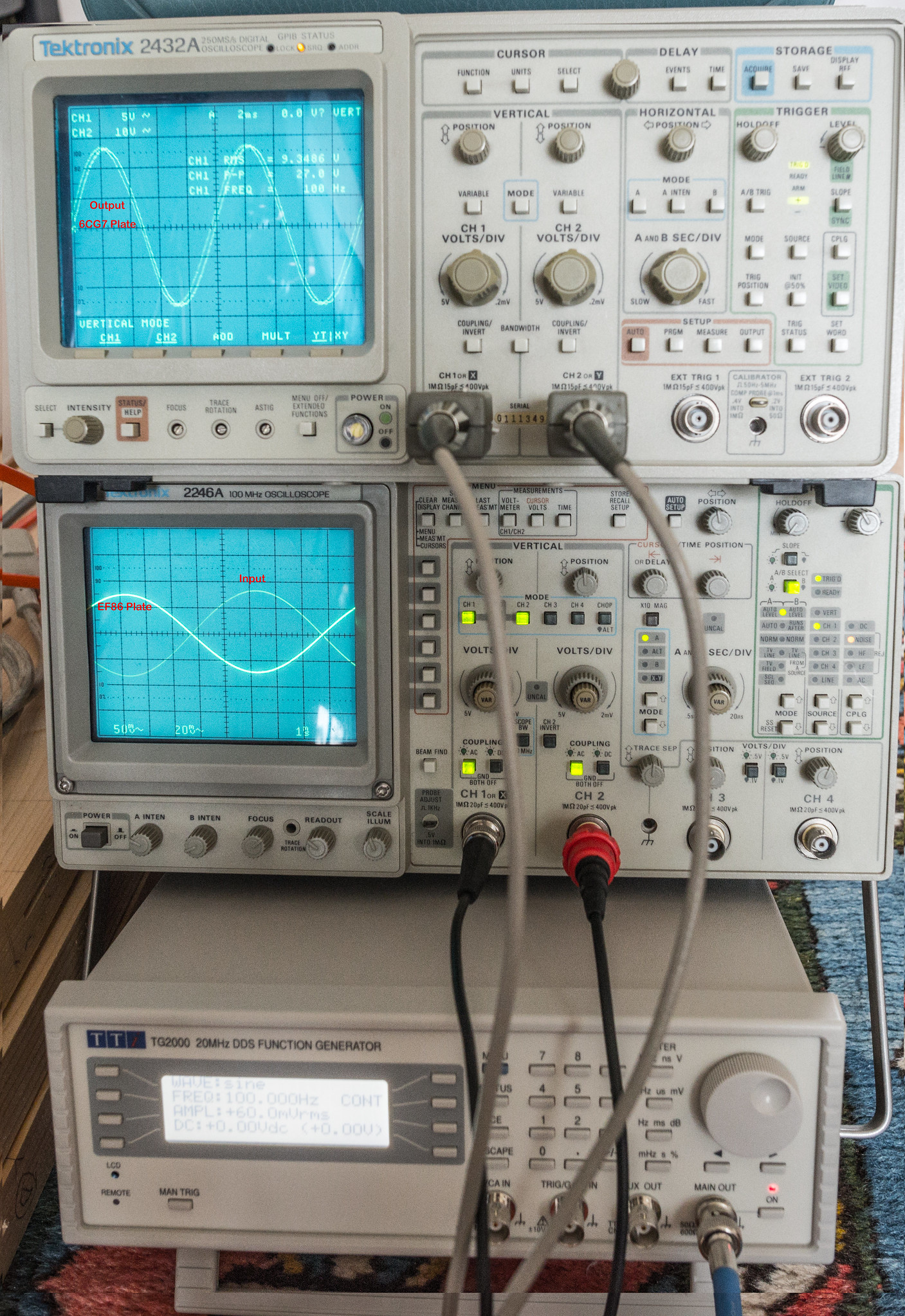

Anyway, closing the loop didn't entirely go to plan as the usual feedback issues returned. However, things were not necessarily as bad as they had been with the previous builds.

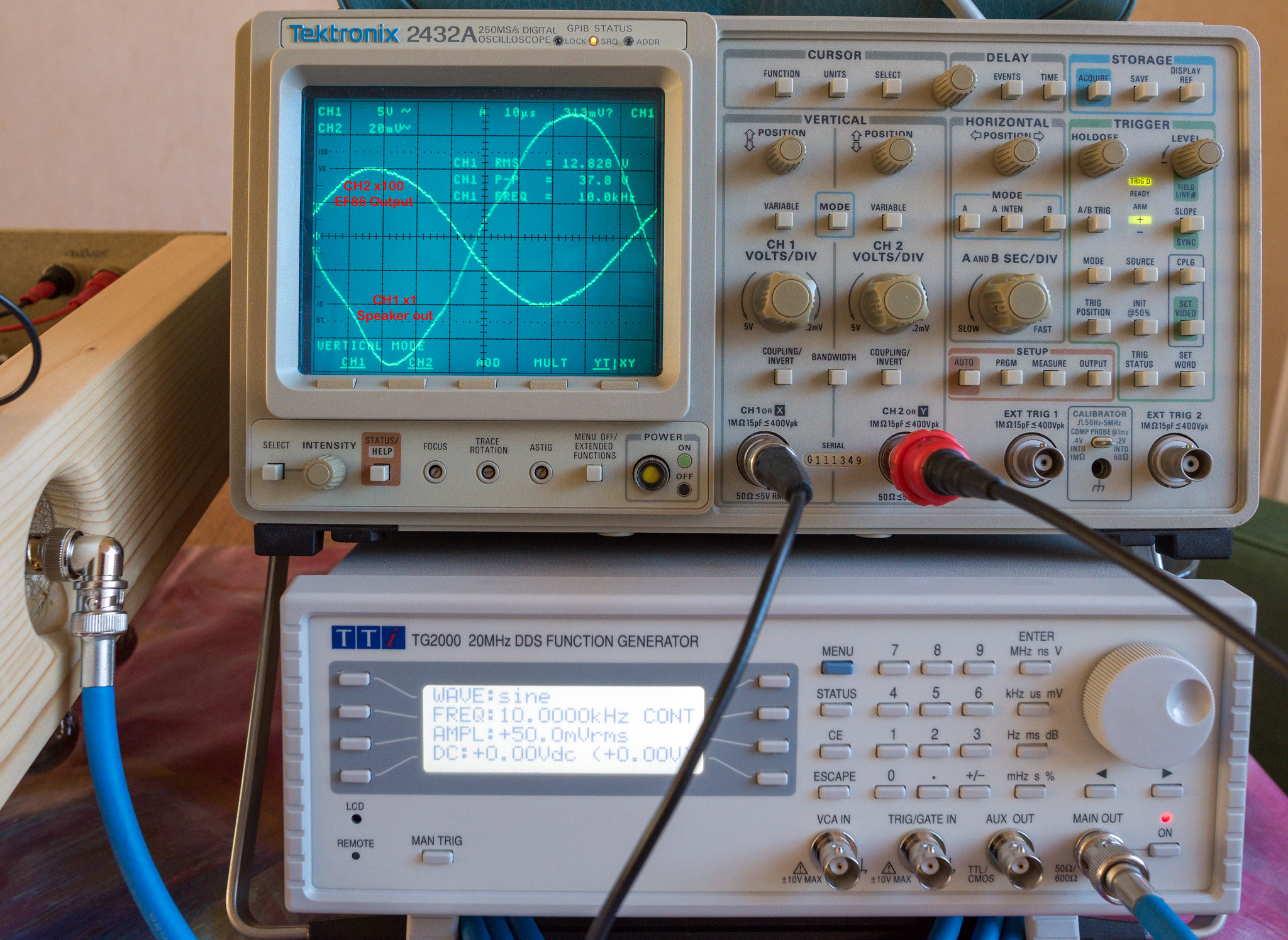

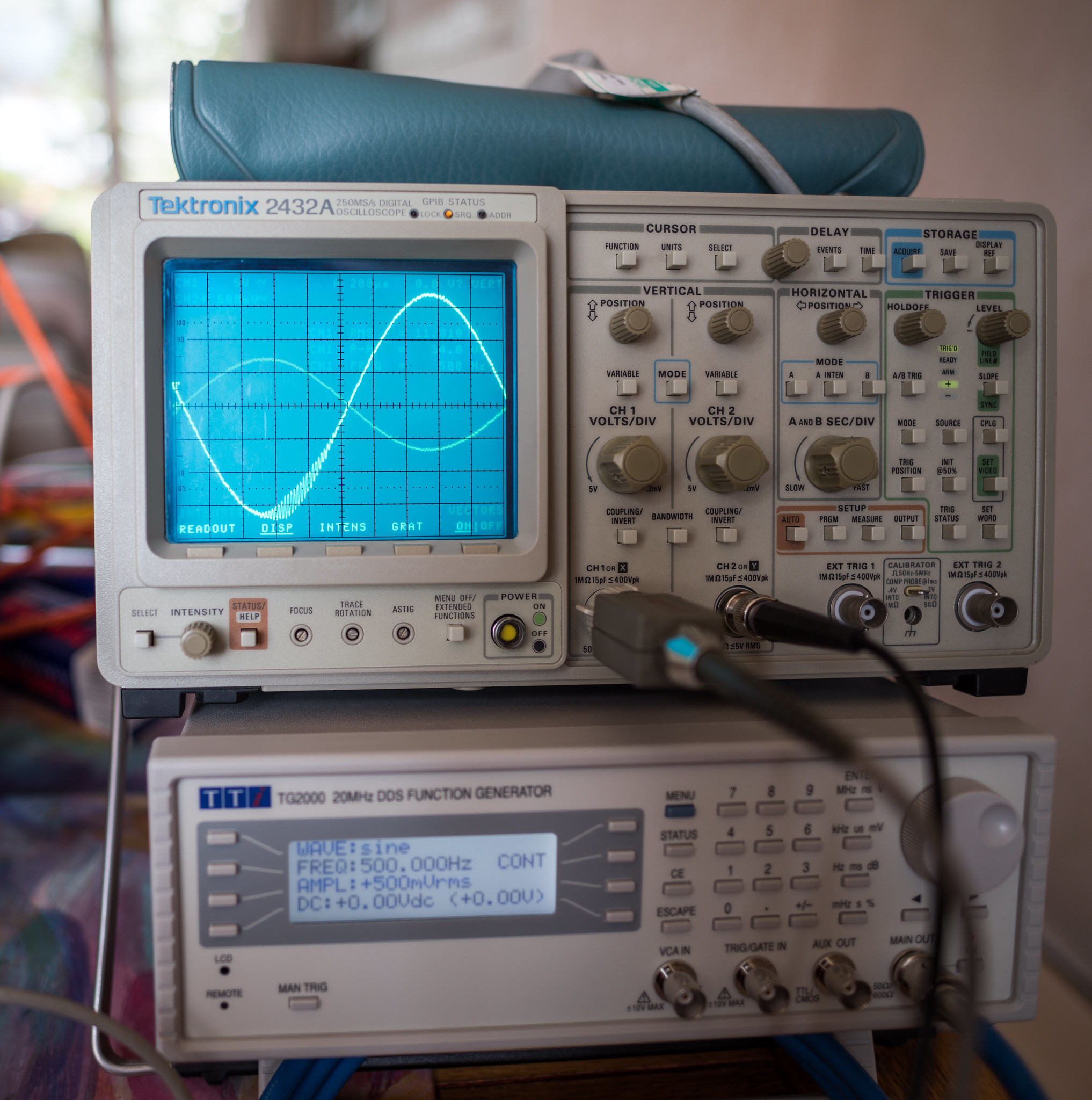

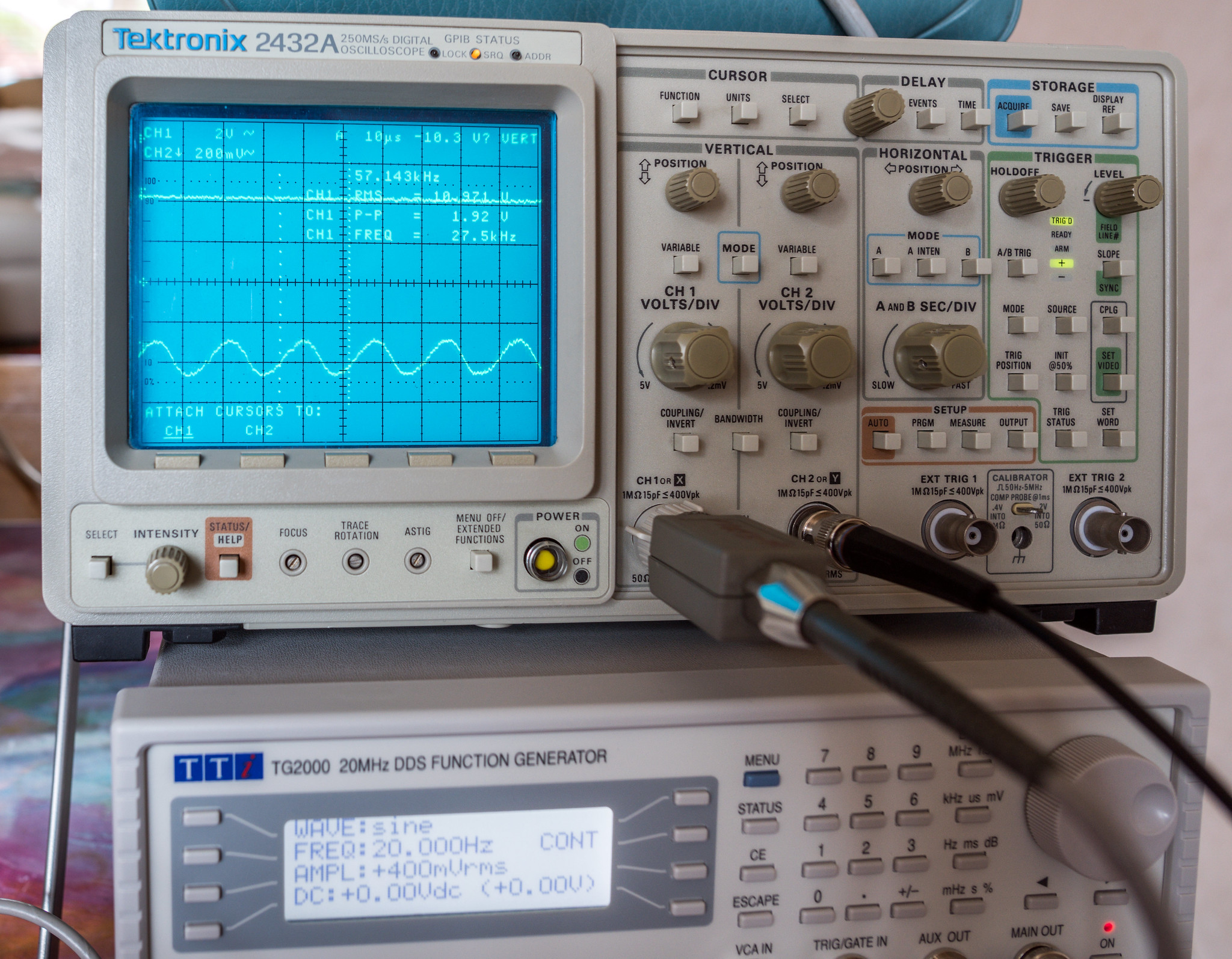

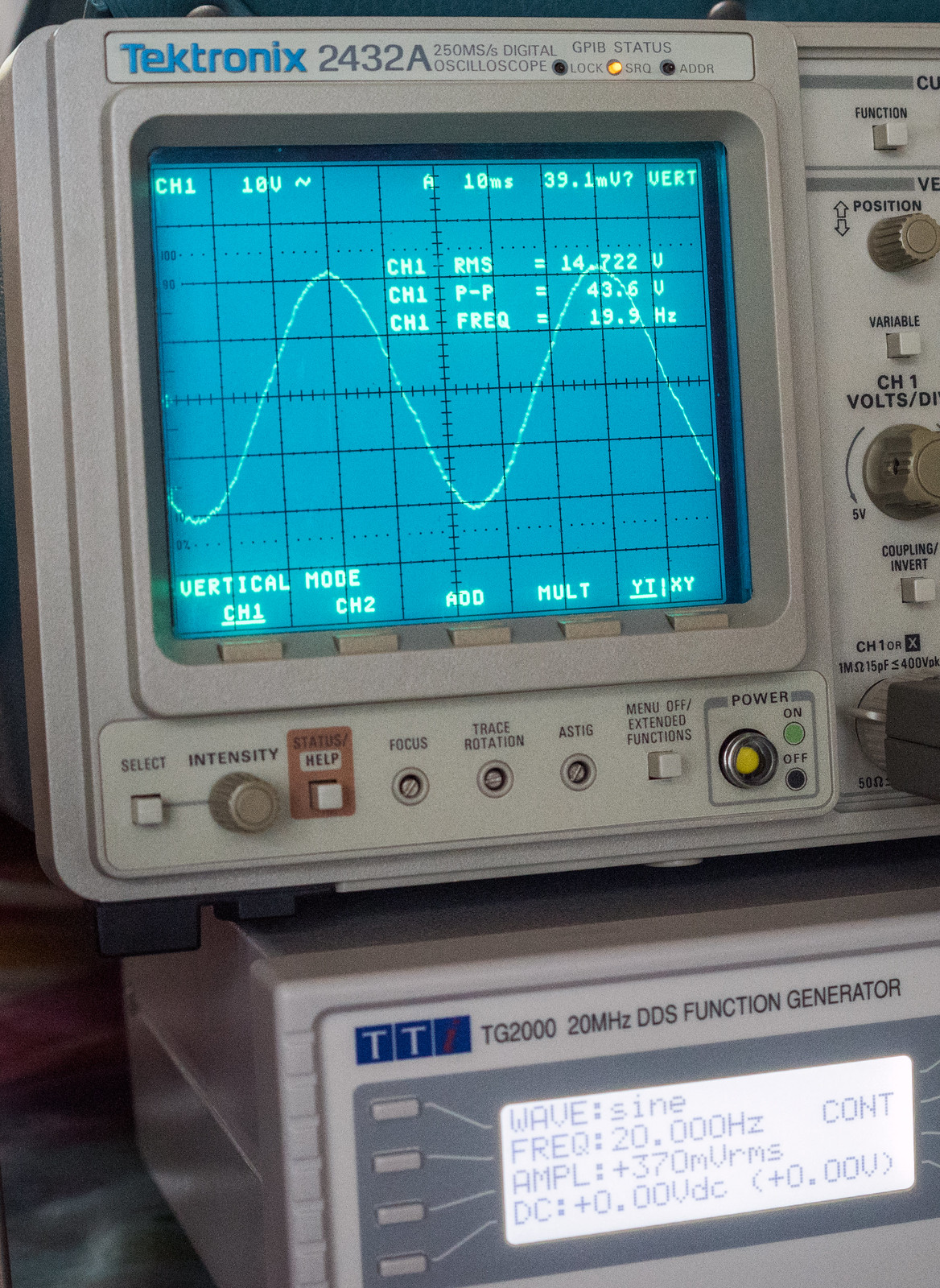

The usual 58ish KHz ringing observed as signal size rises. (shutter speed caught the screen mid refresh hence the dim readout text)

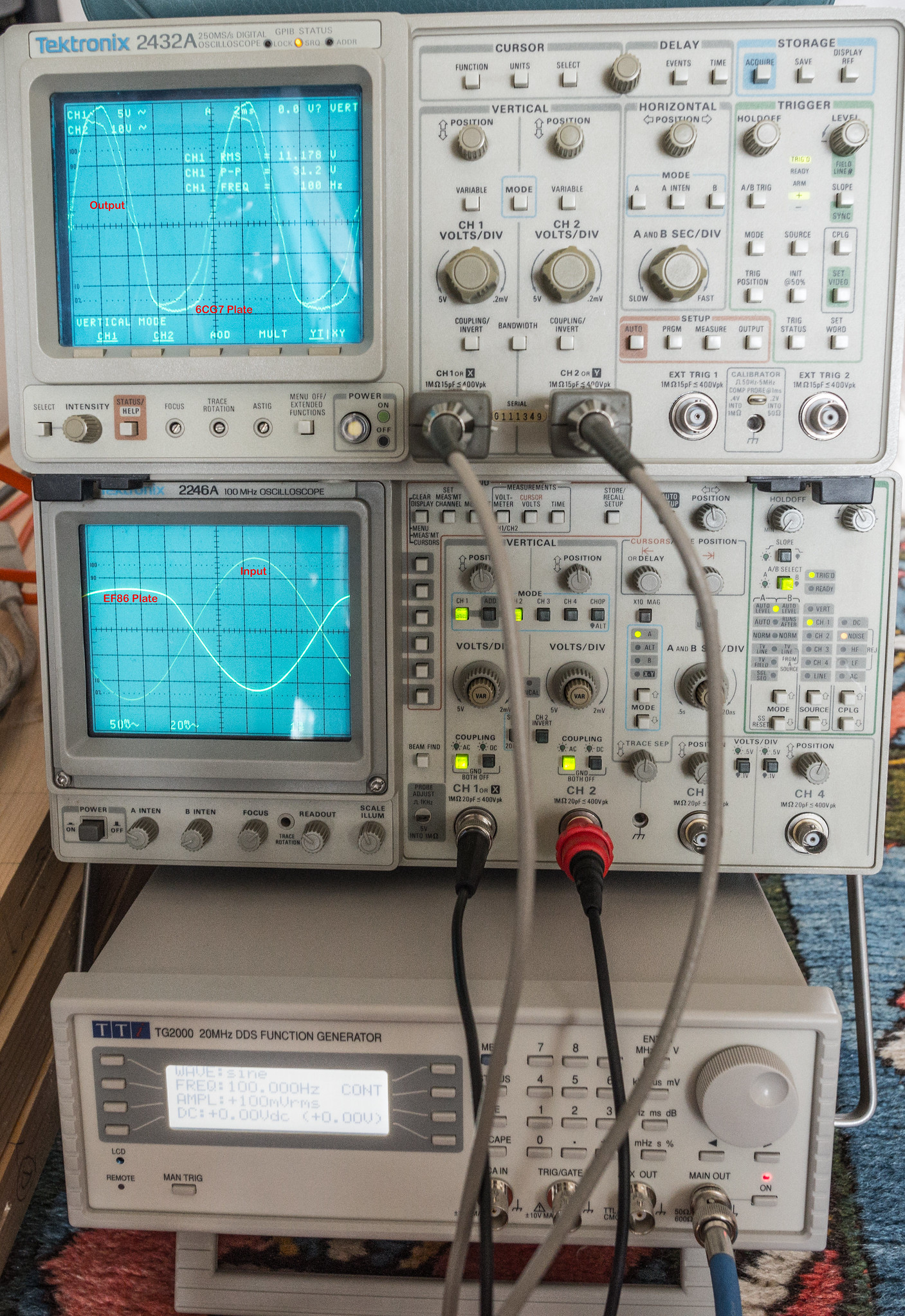

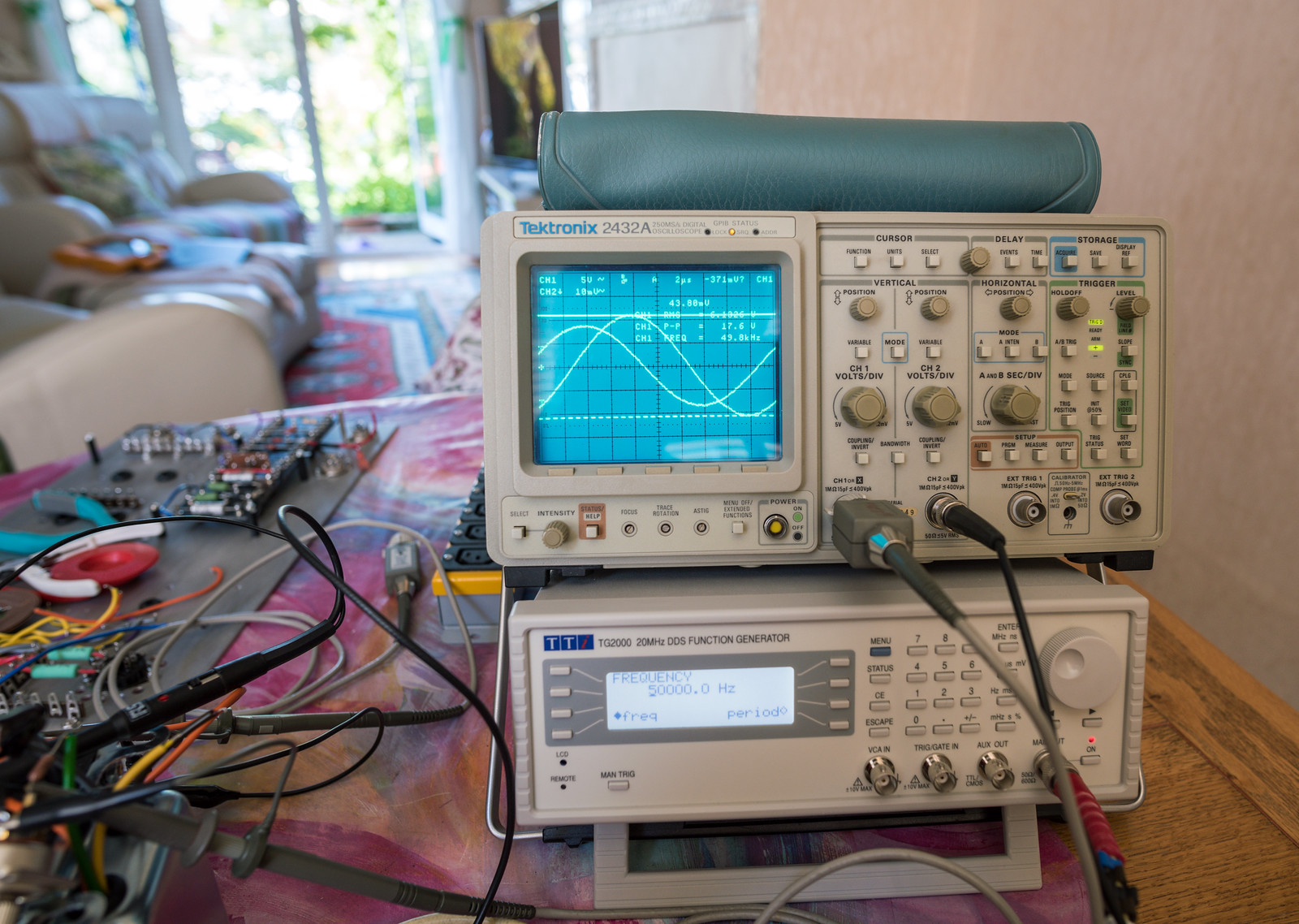

Zoomed in on the oscillation

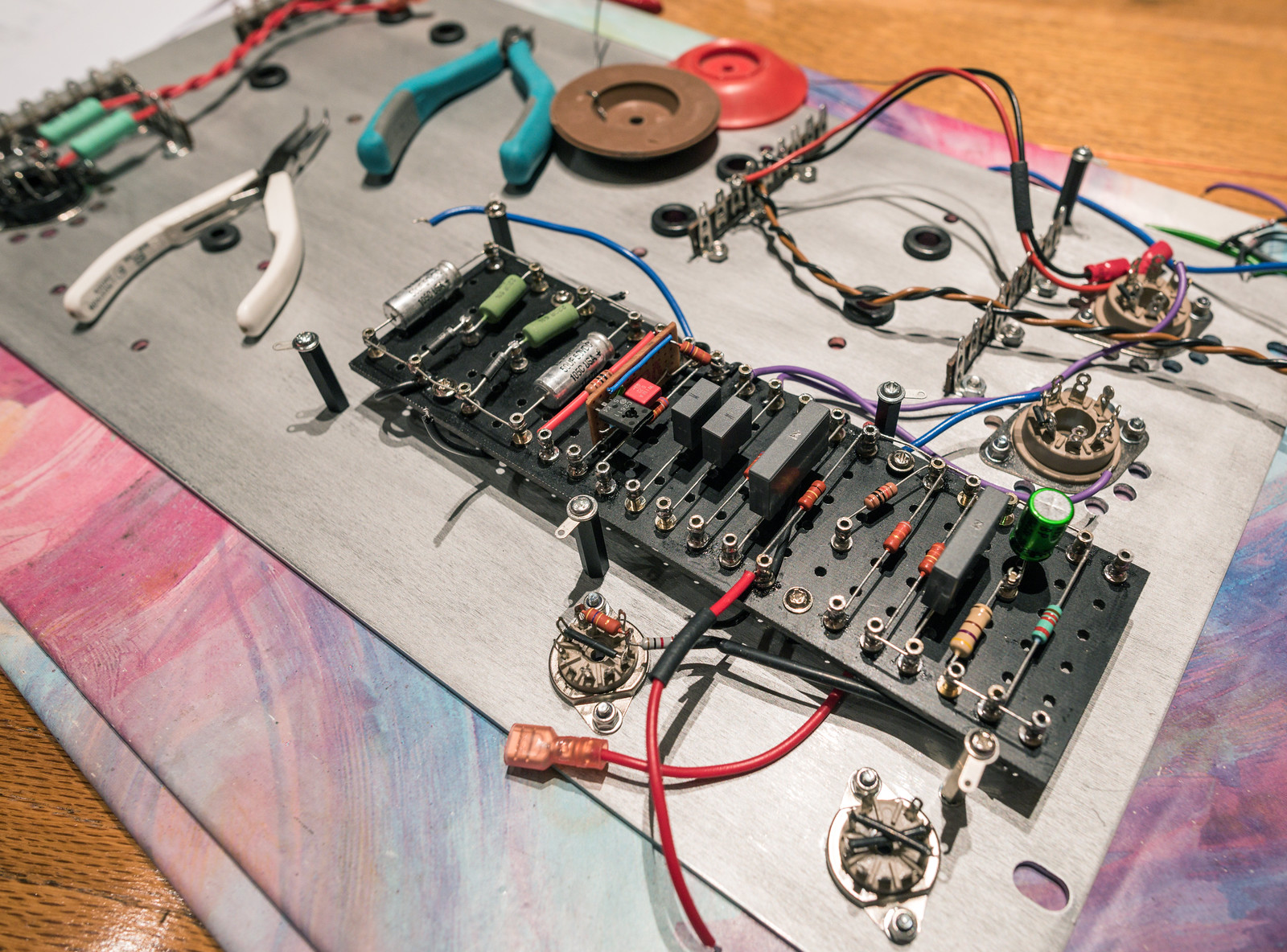

Made some tweaks to some component values which made a decent improvement but didn't fix it.

Comparison at 100Hz 500mV input. Left is C11/C12 @ 100nF & R4 @ 10K, right is C11/C12 @ 470nF & R4 @ 22K. C2 was 270pF for both.

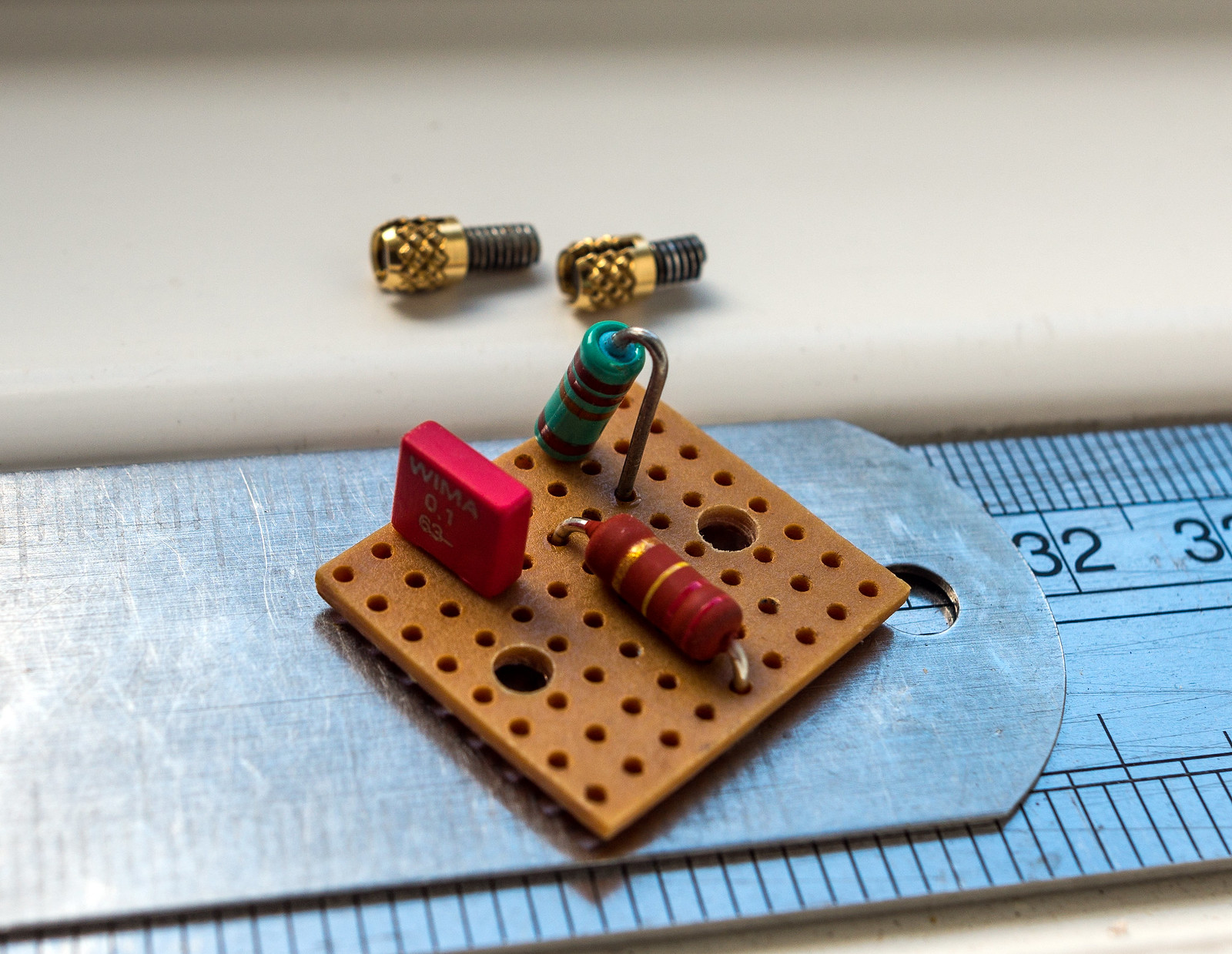

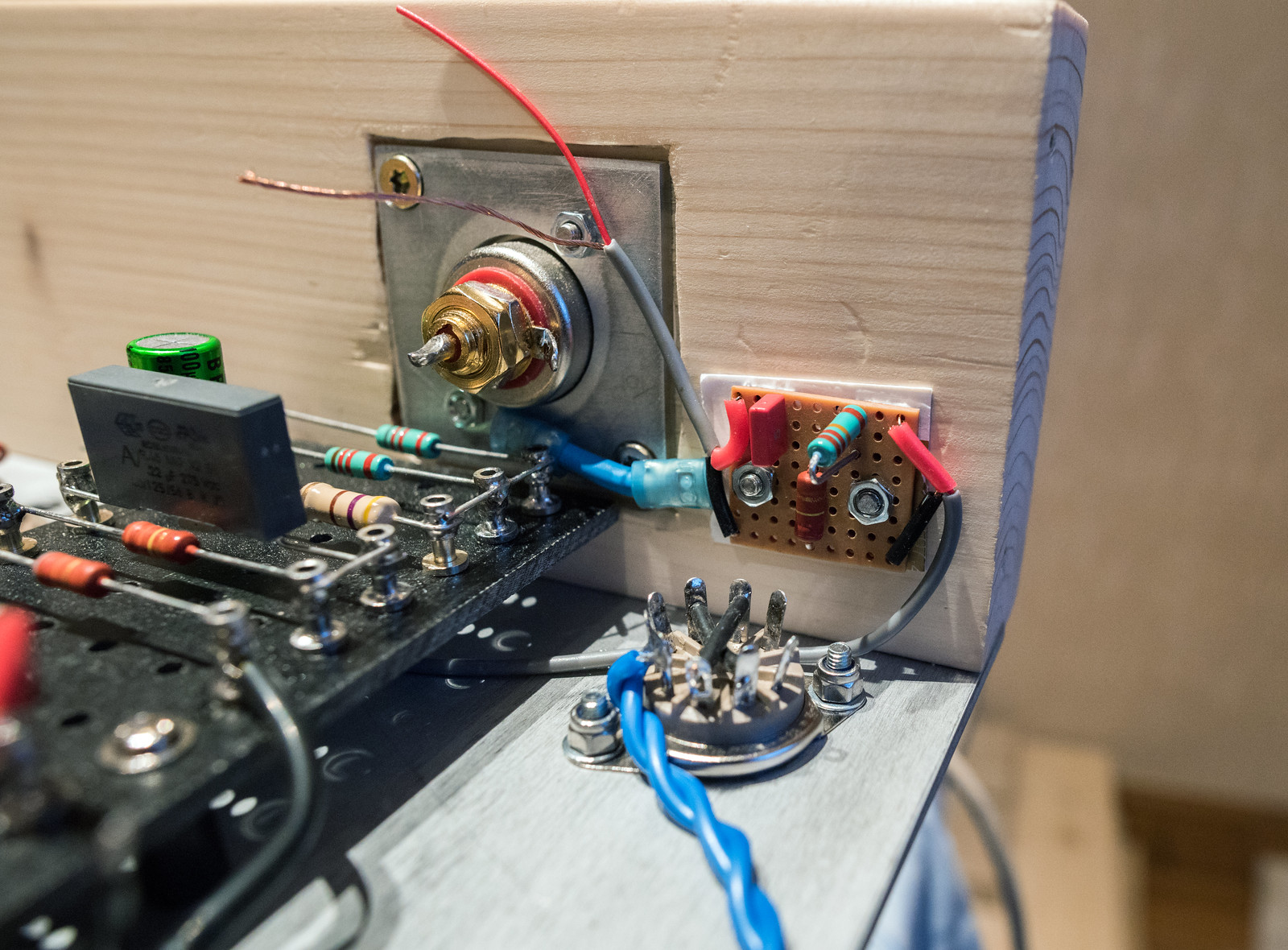

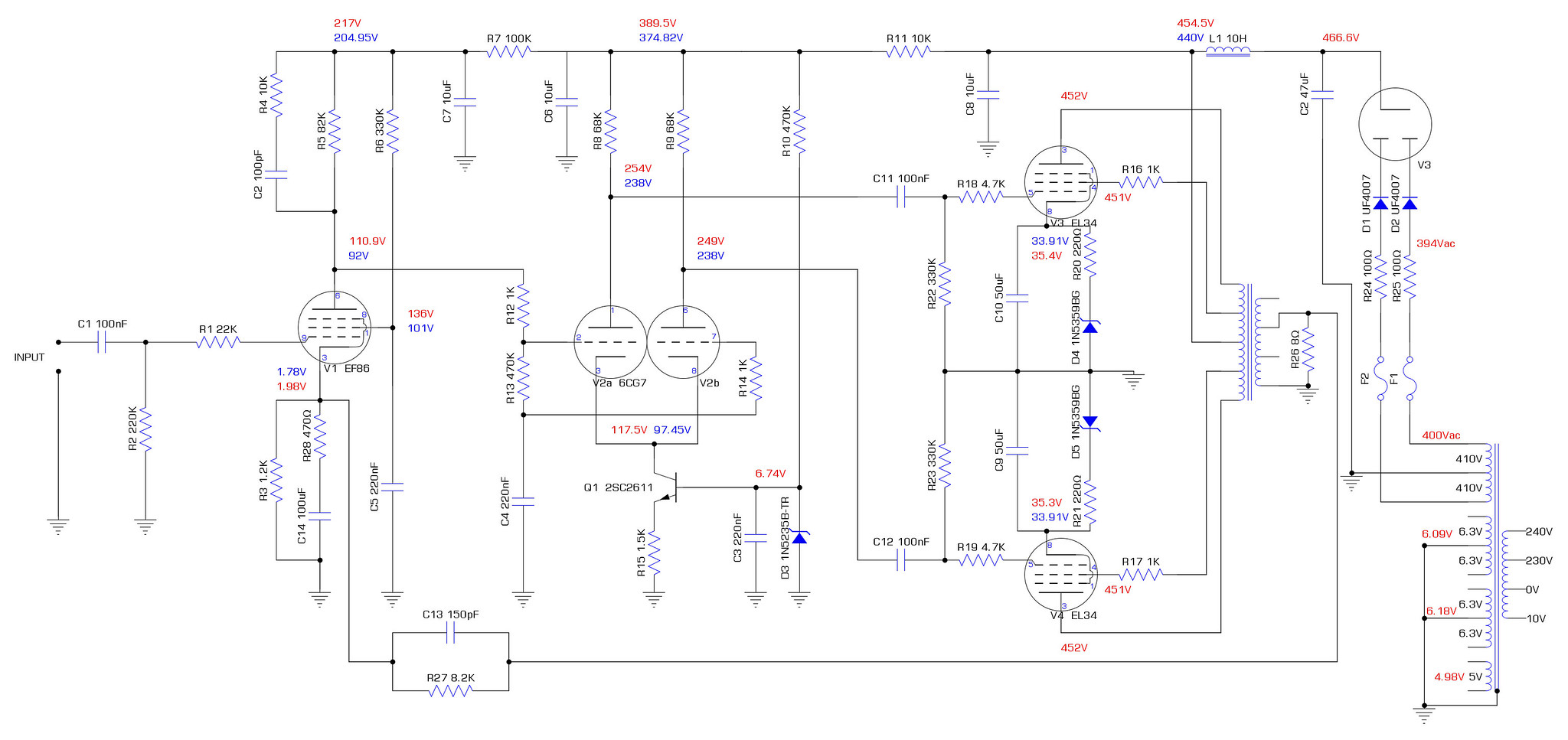

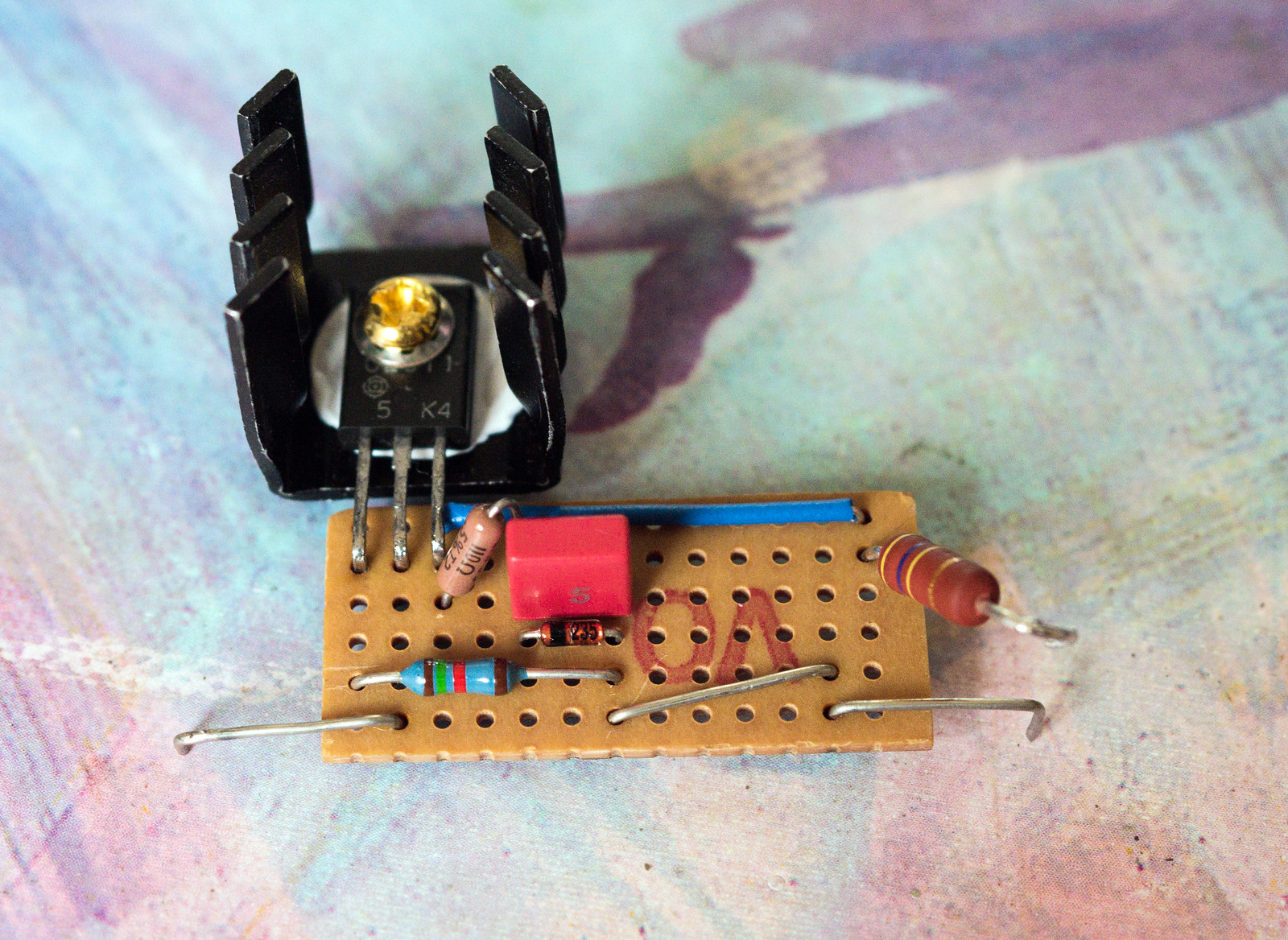

On some suggestions from the DIYaudio folk, I made some further modifications by adding a base stopper resistor on the CCS to make sure that it is unlikely to ever oscillate. A 110R resistor added between the base of the transistor and the capacitor & zener.

I also looked at reducing the amount of feedback as it had been suggested that I may have a greater level of feedback than originally planned. This meant increasing R27 from 8.2K. After a quick search through the components on hand, I put in 10K and rechecked. A small improvement but not much difference.

It made sense at this point to look at how much gain there was in the system at each level in order to figure out where things lay.

Open loop gain = 49.54dB

Closed loop gain with R27 @ 8.2K = 27.31dB (22.23dB feedback)

Closed loop gain with R27 @ 10K = 28.75dB (20.79dB feedback)

That explains a lot. The design calls for 17dB of feedback so even with 10K in there, I'm still way past that point. Looks like I need to up R27 to ~18K and try again. Fingers crossed that does the trick.

Your project makes me feel mine is it actually quite easy, other than feeling like I've been run over every morning!

Your project makes me feel mine is it actually quite easy, other than feeling like I've been run over every morning!