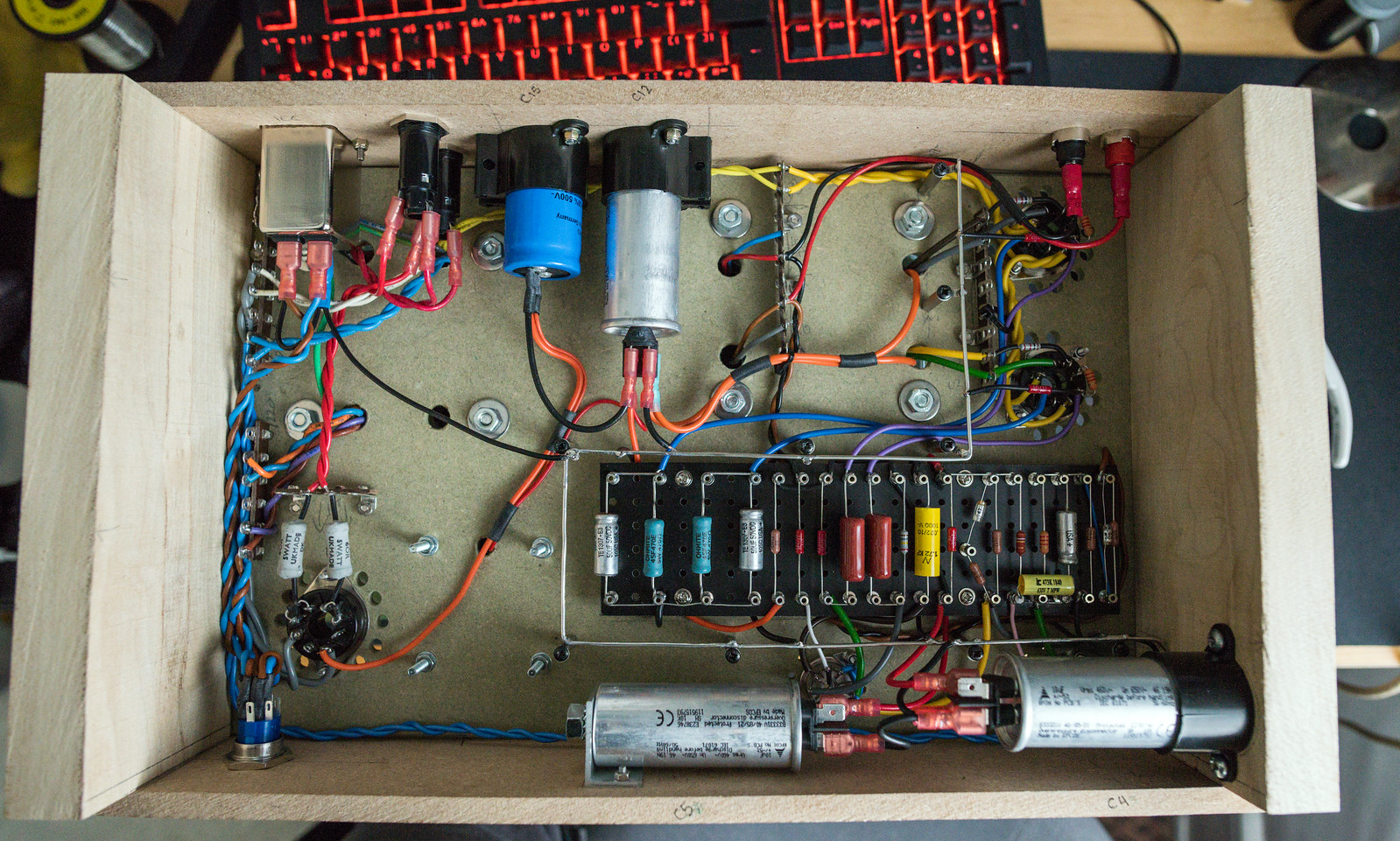

I finished off the wiring at the very end of April. Wired the mains push button switch in this time which is very nice.

Testing the amp proved that the problems I had with the first build were not related to the layout. Still cooking valves for no good reason.

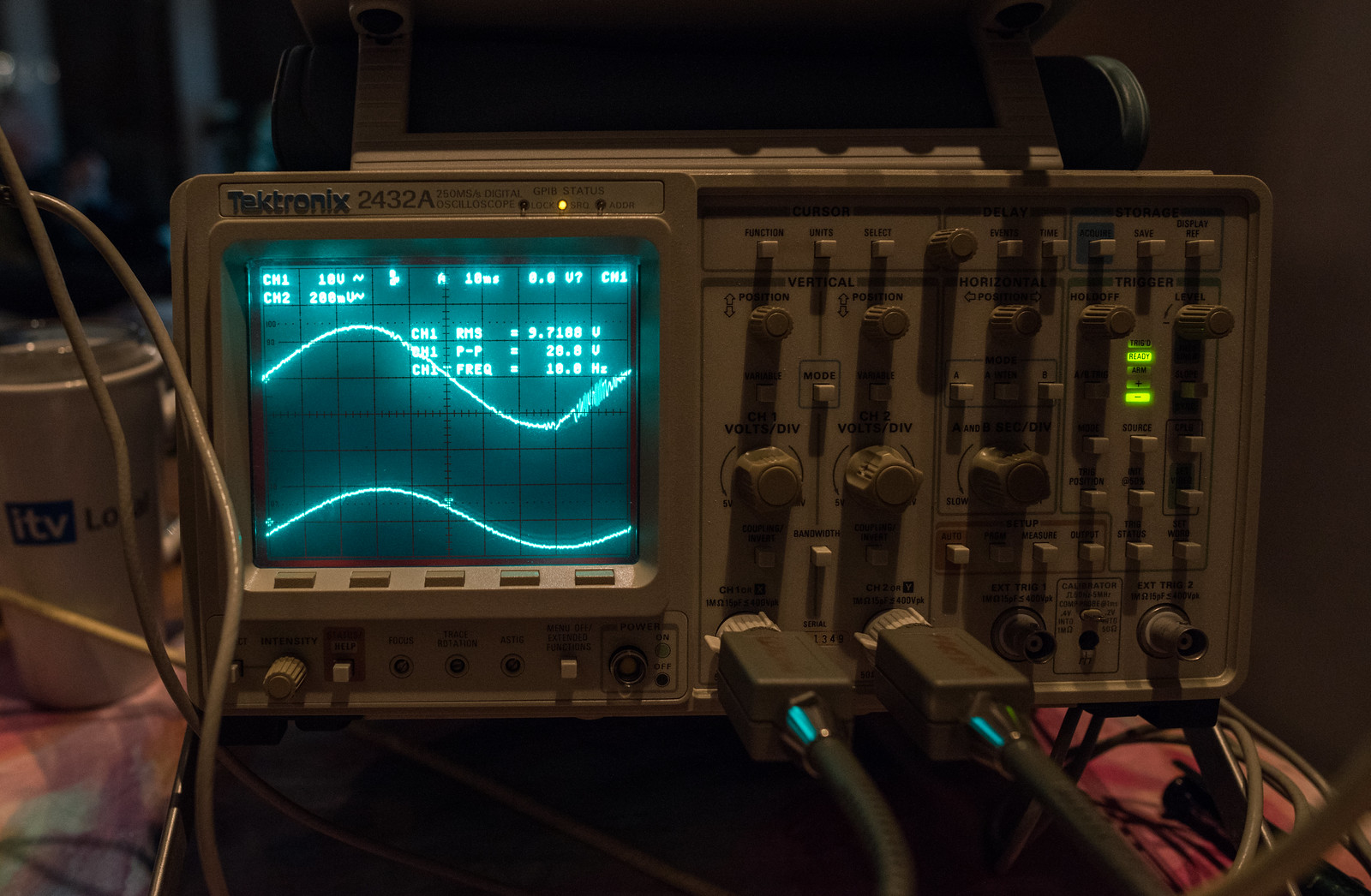

and still getting unsettled towards the 20W it should be able to output cleanly.

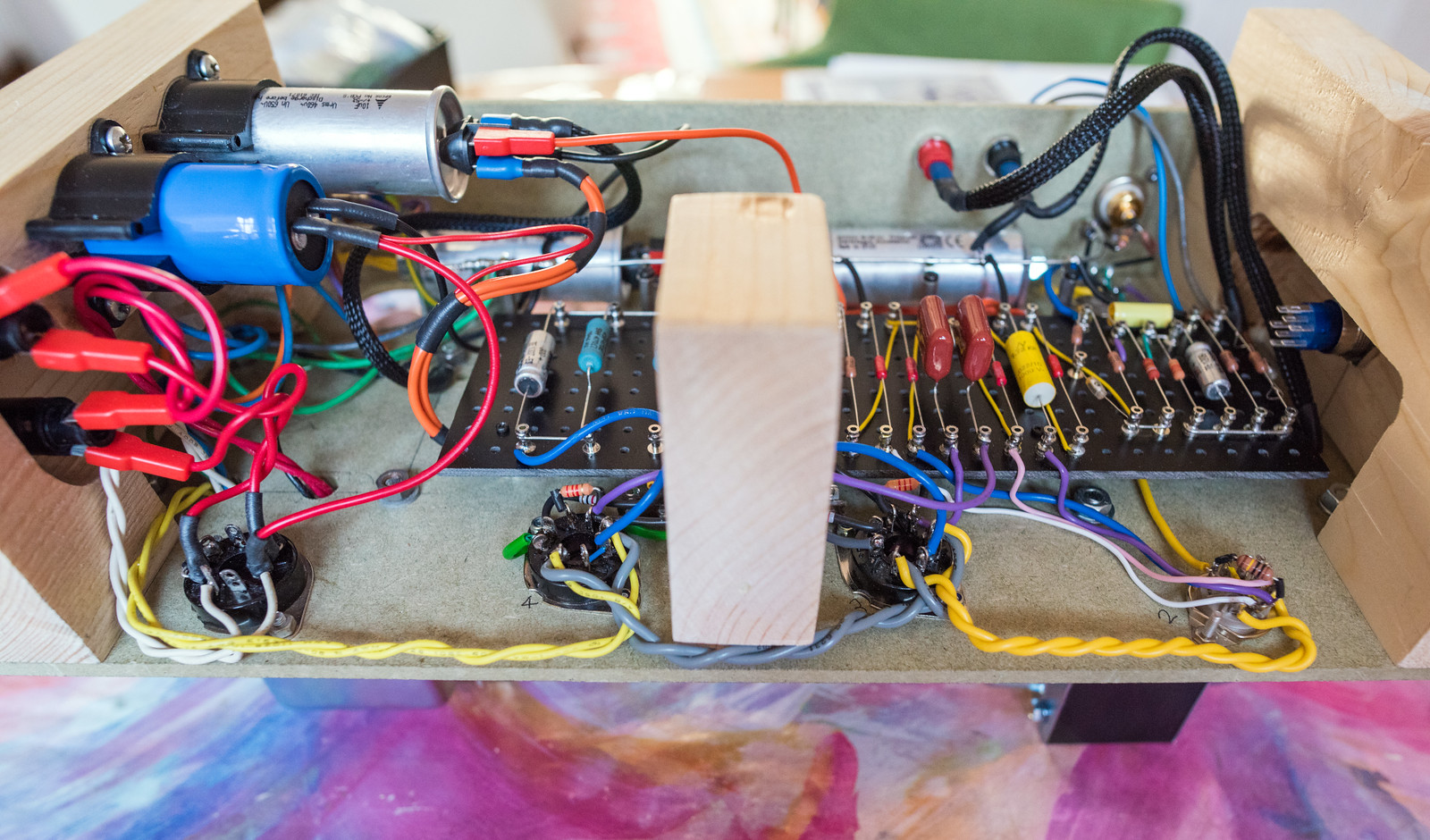

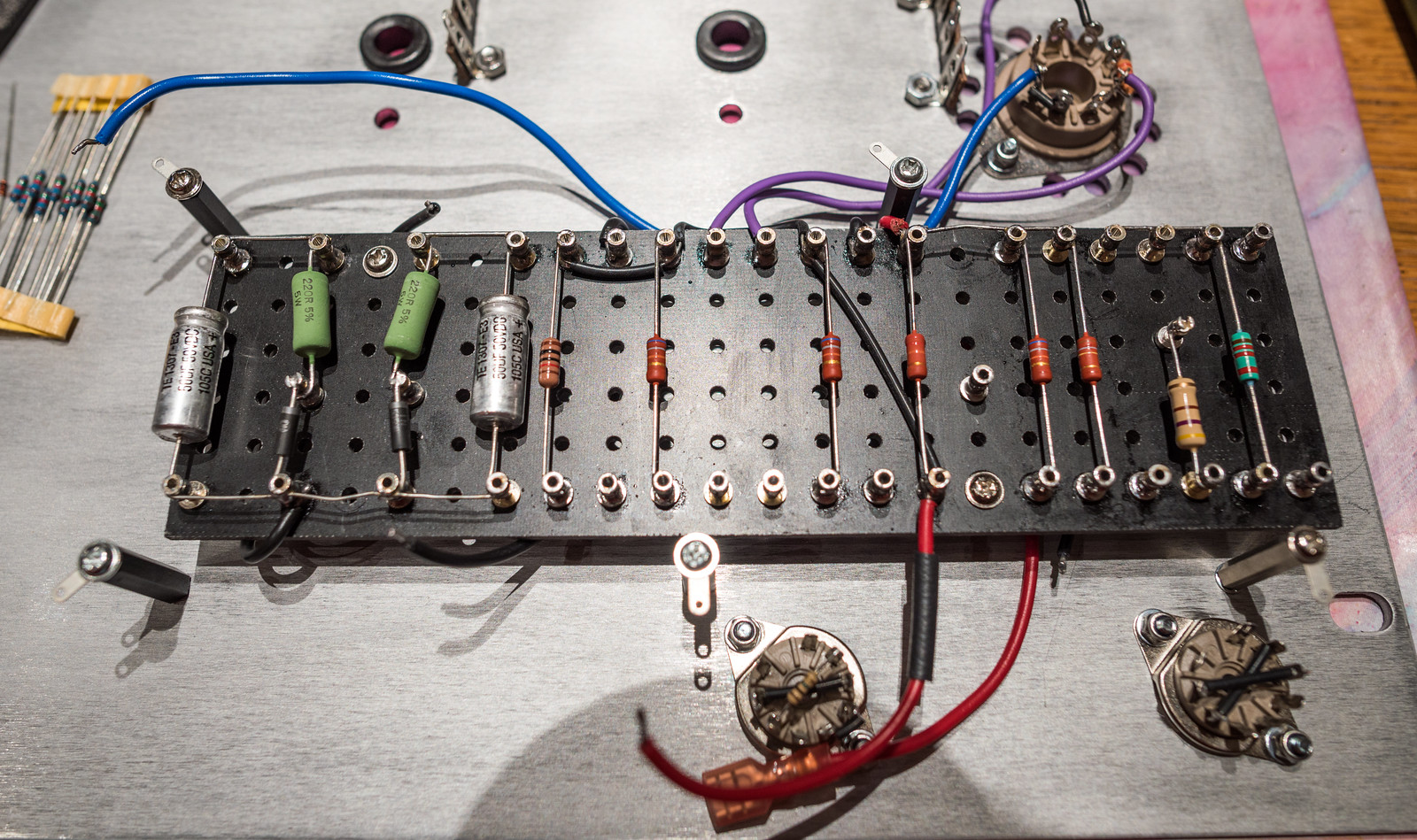

This led to me looking at the Claus Byrith modifications which converts the front end from a pentode input to triode strapped input. The rest of the modifications are far more difficult to achieve as it would require a negative supply. This has the alterations needed to the turret board. Thankfully it's simply removing a few components and swapping others. No need for removing or changing the turrets themselves.

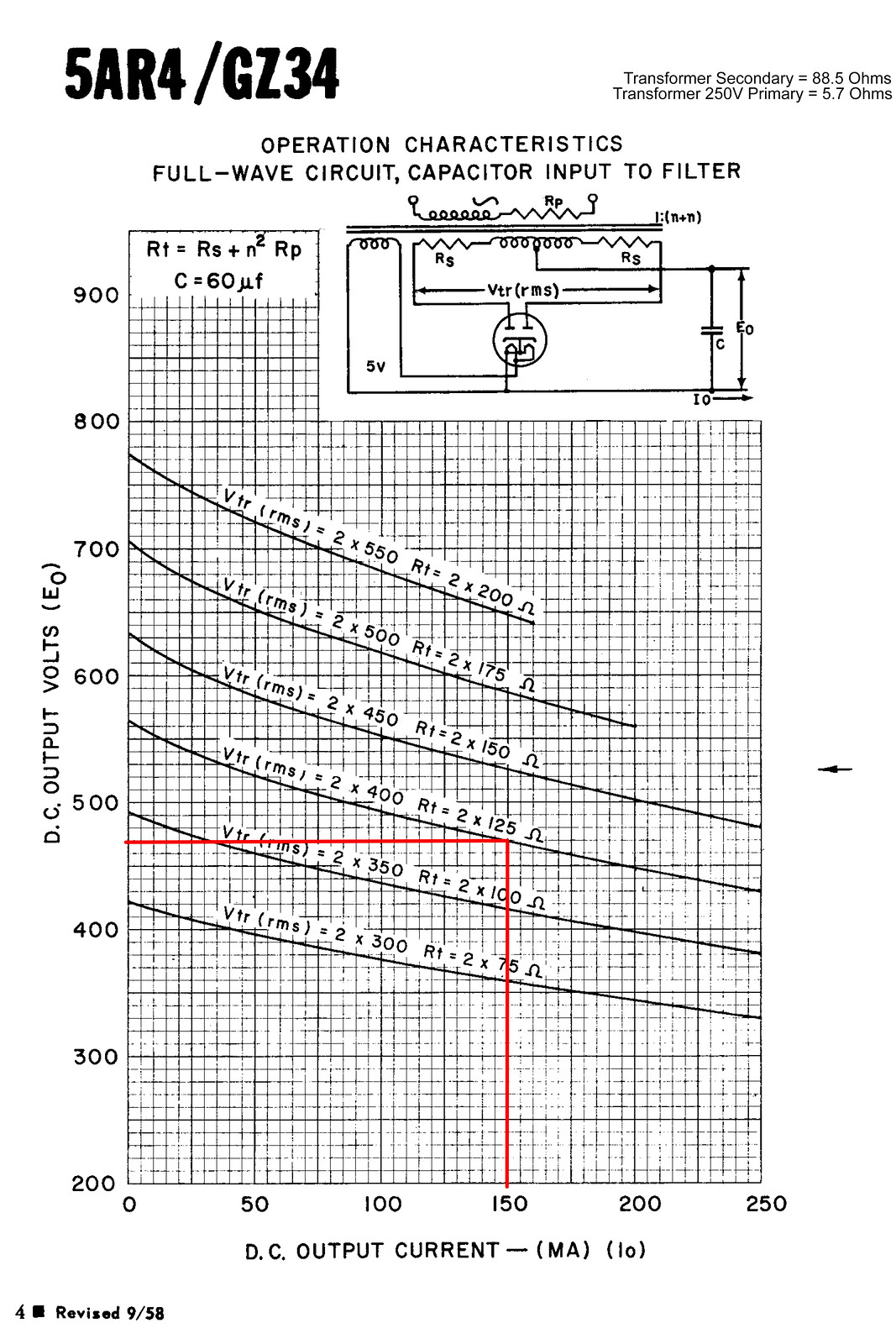

Schematic for this design.

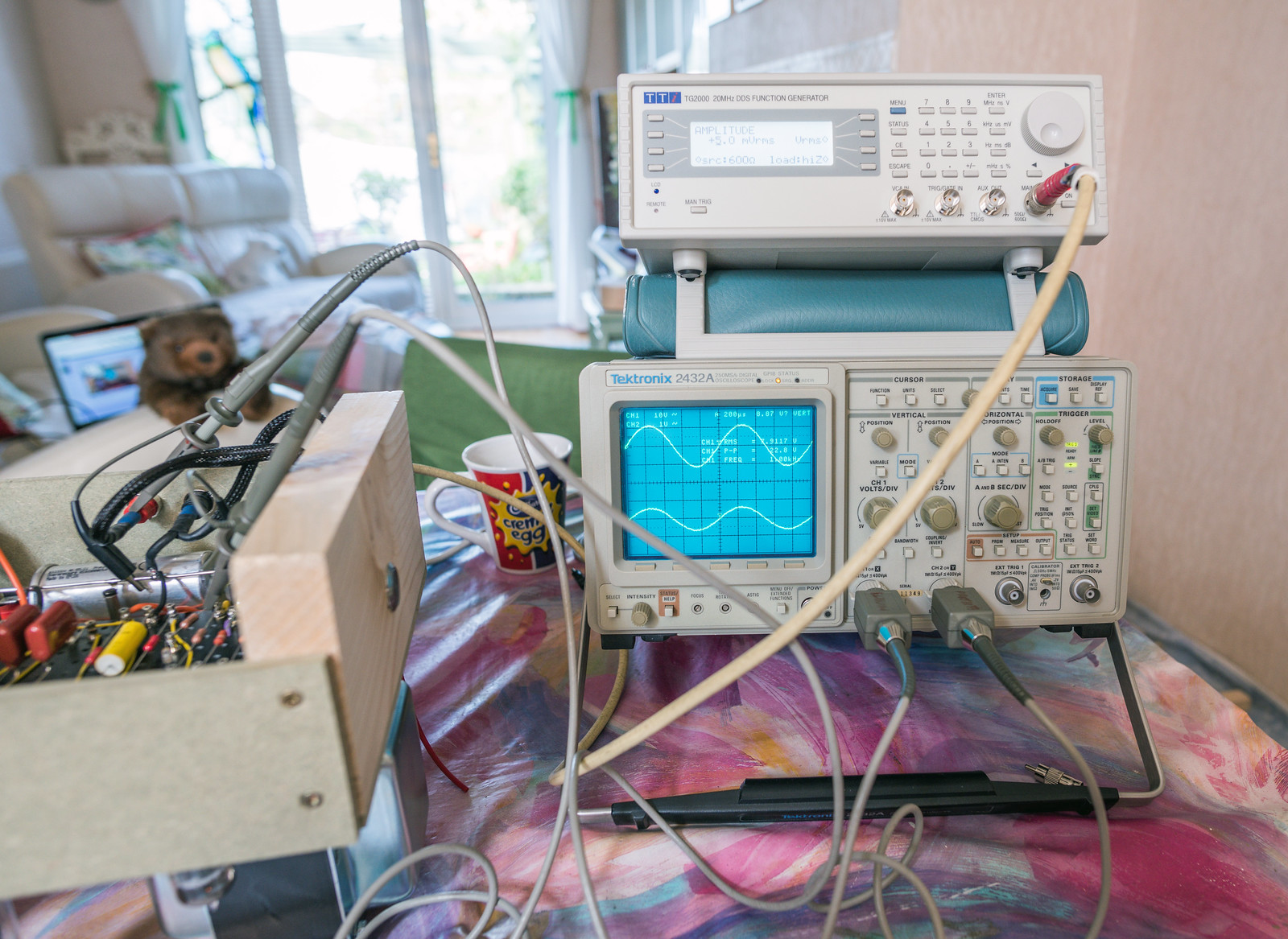

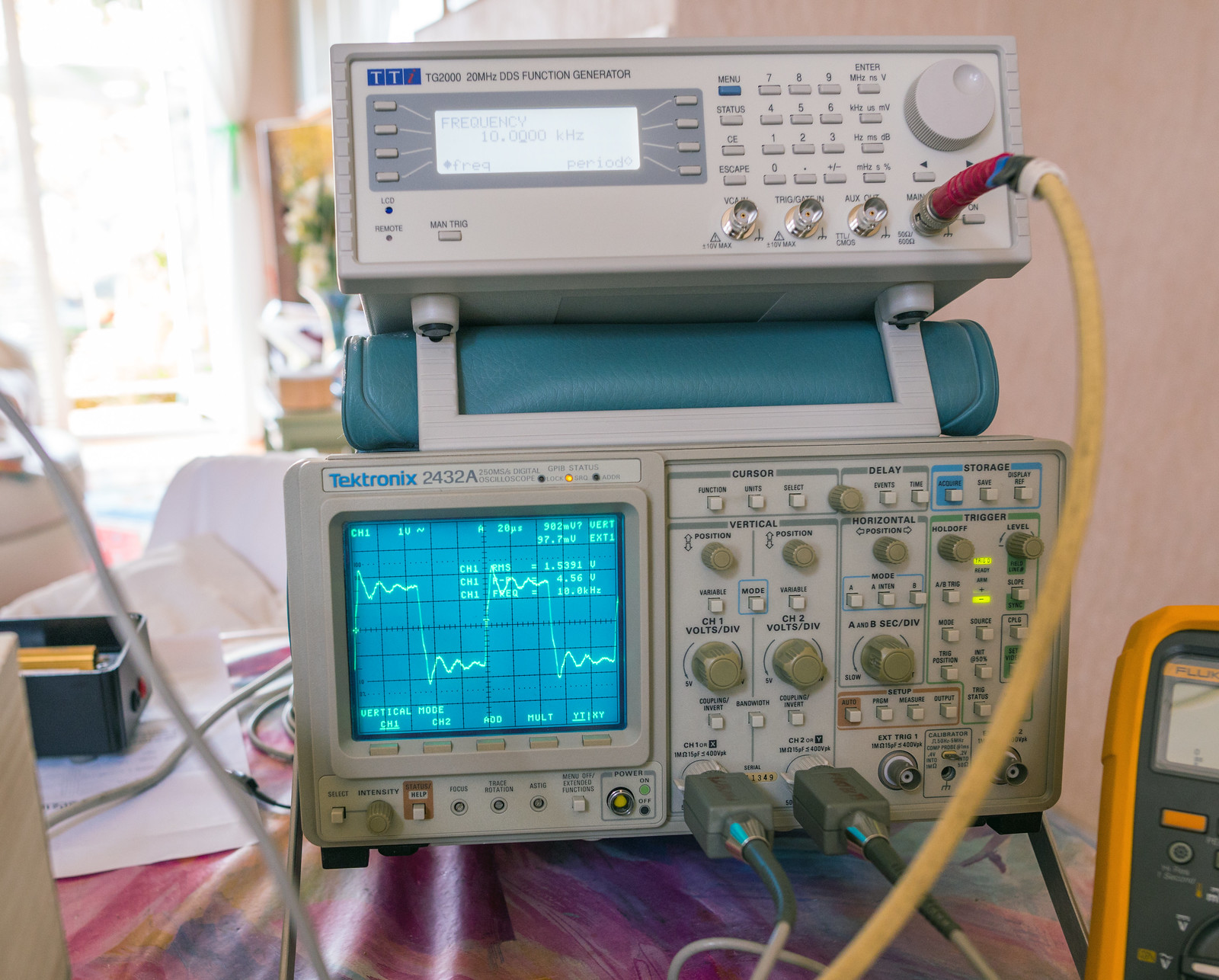

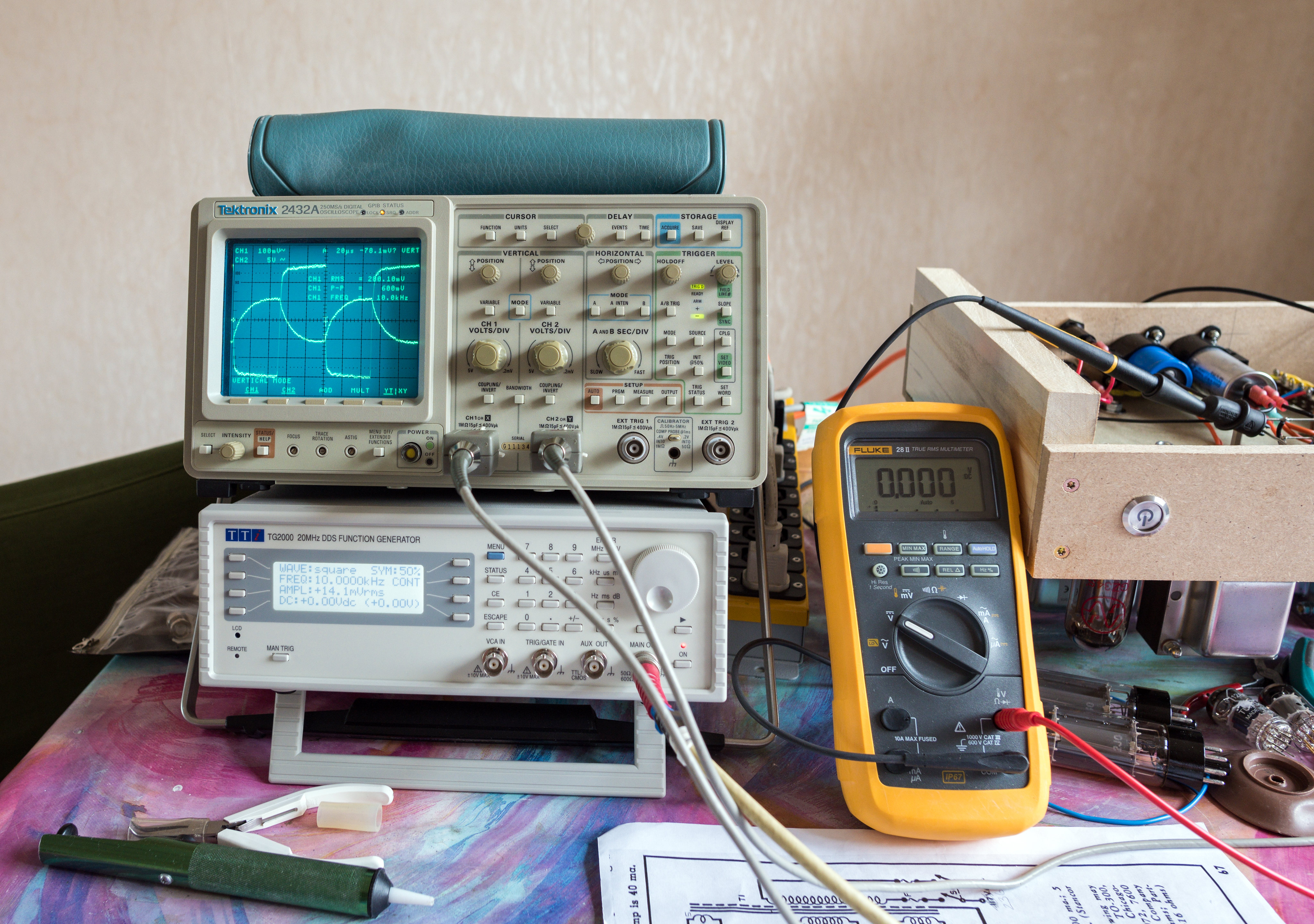

This tested significantly better albeit with some issues still lingering so I ended up disconnecting the feedback completely and running some open loop tests between the anodes of the input valve and the phase splitter as there is definitely something iffy going on. 10KHz square wave input, close to square out of the EF86, utter crap out of the 12AX7.

Took the EL34's out of circuit and tested again. Very suspicious. It definitely looks like the above issue related to stray capacitance.

Someone suggested that the octal sockets having the stray capacitance was a real possibility since the above was measured at the point the signal would enter the grid of the EL34. I replaced the old finder sockets with some new belton ones. Things improved a bit.

I'm now working on constructing the metal chassis from scratch with some spare scrap aluminium I have floating around. (19" 6U rack blanking plates) I was thinking of using aluminium U channel to make up the sides, but having seen

@Sam__ 's scratch build project, that bosch rexroth aluminium extrusion system looks very interesting, if perhaps a bit expensive.