I've been using it regularly since the start of August and it's been running great. It sounds superb. It's surprising just how loud 20-30W is capable of. Having resampled all of the valves, at best, the differences between them are subtle. I'm currently sticking with the JJ KT77's as they are a matched pair rather than a quartet and they are also the cheapest so I can wear these down whilst I work on building the second amp. Swapping valves around all the time isn't going to bode well for the sockets or the valves and I wouldn't want to wear half a quartet. I'll use the quartets once I have both amps finished. Currently I've got the left channel powered by my solid state amp and the right channel via the valve amp. They sound remarkably similar, though I think the valve amp has a tubbier bass which I reckon is down to the low damping factor due to the higher output impedance.

I moved it from behind the door to where the turntable was which has helped with cooling. The turntable needed to move anyway as the top of the "flexi-rack" is not stable enough for the turntable. I had to tip toe around whenever it was on. That will get it's own wall shelf at some point.

Did another video with better audio this time. (albeit worse IQ)

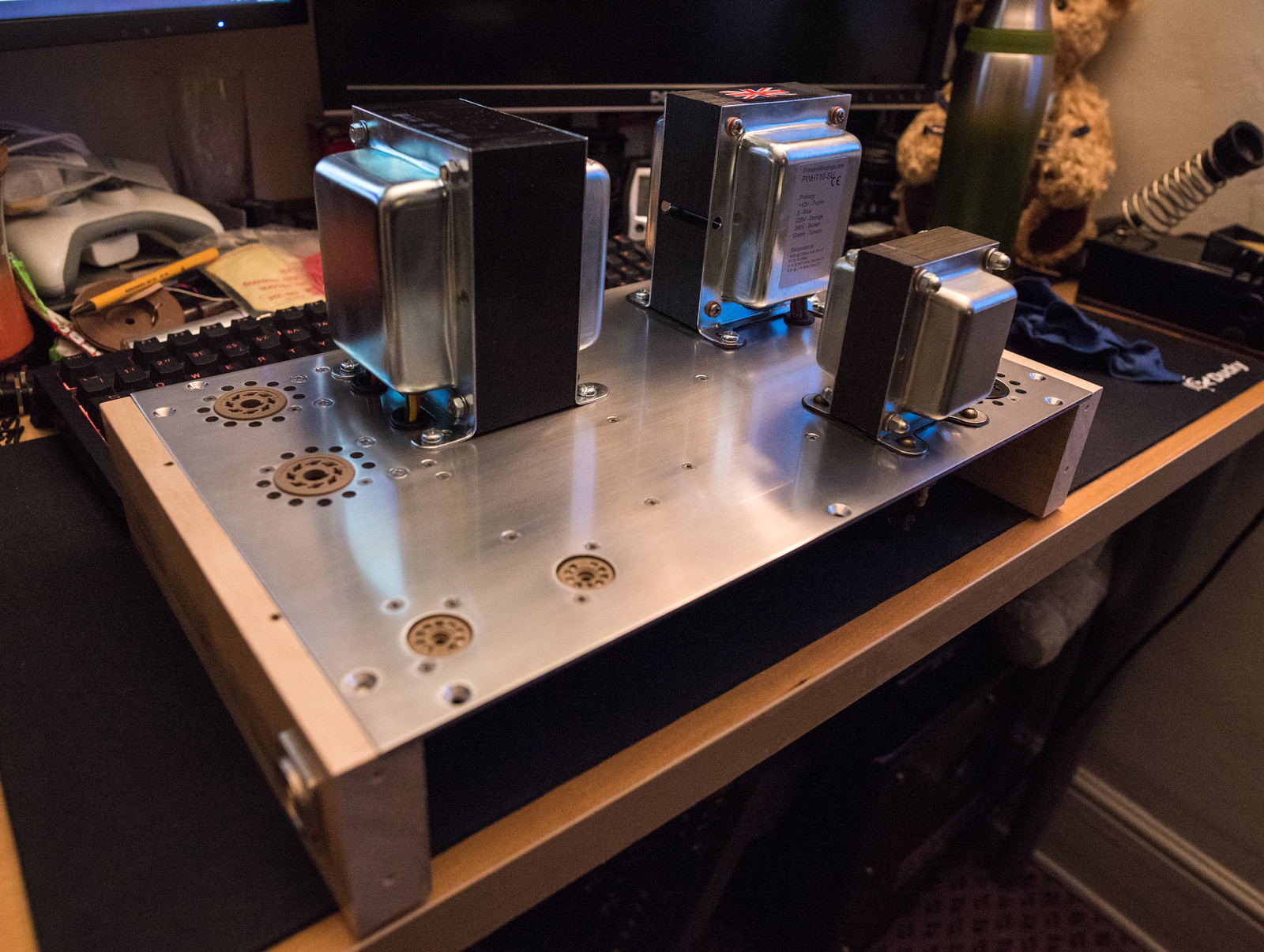

I'm still working on the "how to build an all metal chassis" issue. I'm torn between the simpler 3mm aluminium plate on a wooden frame like I've already build against an all metal box like a hammond 1444 folded aluminium chassis. An american company called Landfall Systems seems to make an extremely good looking item but shipping and taxes are likely to be painful.

I moved it from behind the door to where the turntable was which has helped with cooling. The turntable needed to move anyway as the top of the "flexi-rack" is not stable enough for the turntable. I had to tip toe around whenever it was on. That will get it's own wall shelf at some point.

Did another video with better audio this time. (albeit worse IQ)

I'm still working on the "how to build an all metal chassis" issue. I'm torn between the simpler 3mm aluminium plate on a wooden frame like I've already build against an all metal box like a hammond 1444 folded aluminium chassis. An american company called Landfall Systems seems to make an extremely good looking item but shipping and taxes are likely to be painful.

Last edited: