You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Left Handed Build

- Thread starter piggin

- Start date

More options

Thread starter's postsAssociate

- Joined

- 7 Sep 2007

- Posts

- 1,222

- Location

- UK

Wow - stunning looking build so far, looks like a professional concept case.

I would be interested in hearing the mechanics of laser cutting. Do you need some CAD software that you give to the laser cutter firm? How long does it take? Approx cost etc?

Anything you can share without getting in trouble with "you-know-who" would be much appreciated.

Anything you can share without getting in trouble with "you-know-who" would be much appreciated.

not keen on the fan grills but they are certainly different.

Personally I really like the look of the fan grills, but I do wonder if their asymmetry might cause turbulence and perhaps unwanted noise.... Perhaps not if the fans are really slow. I guess piggin will soon find out!

Wow - stunning looking build so far, looks like a professional concept case.

Thanks Rhodri, I was going with a Mountain Mods style case.

I would be interested in hearing the mechanics of laser cutting. Do you need some CAD software that you give to the laser cutter firm? How long does it take? Approx cost etc?

Anything you can share without getting in trouble with "you-know-who" would be much appreciated.

All the panels came through (can't put the name up as they are competitors but they do water cooling for Pc's & come from Bridgend, south wales)

You can supply them with drawings (CAD or paper) & they will do the rest. As for time & cost, that depends on what you want & how deep your pockets are.

very nice

not keen on the fan grills but they are certainly different.

the quality of the work so far is superb.

nice one piggin

Thank you rjkoneil for your praise

I understand that this design will not be to everyone's taste but I like it & its different.

Maybe I can start my own trend for individual case design

Personally I really like the look of the fan grills, but I do wonder if their asymmetry might cause turbulence and perhaps unwanted noise.... Perhaps not if the fans are really slow. I guess piggin will soon find out!

John, all the fans will be run through zalman fan controllers, so noise will not be a problem (fingers crossed)

As you said, I will soon find out.

Soldato

- Joined

- 16 Nov 2010

- Posts

- 16,513

- Location

- Swimming in a lake

It's finally here! No more desk computer

Looks good though!

kd

Looks good though!

kd

Just went through all 8 pages and this has to be the best thread I've read here on overclockers forums. Love the dedication and motivation you have mate, can't wait to see the final build

Subbed!

P.S. EK Rings are the way to go!

Thanks nayan, I am very happy that you have enjoyed my thread.

Hopefully you have enjoyed it for its technical merit

It was always my intention to make this 'light hearted' & enjoyable for others.

As for the EK ring, its the only way to go

It's finally here! No more desk computer

Looks good though!

kd

Thanks KD, 'The Shelf' will be a thing of the past soon & Mrs Piggin can't wait.

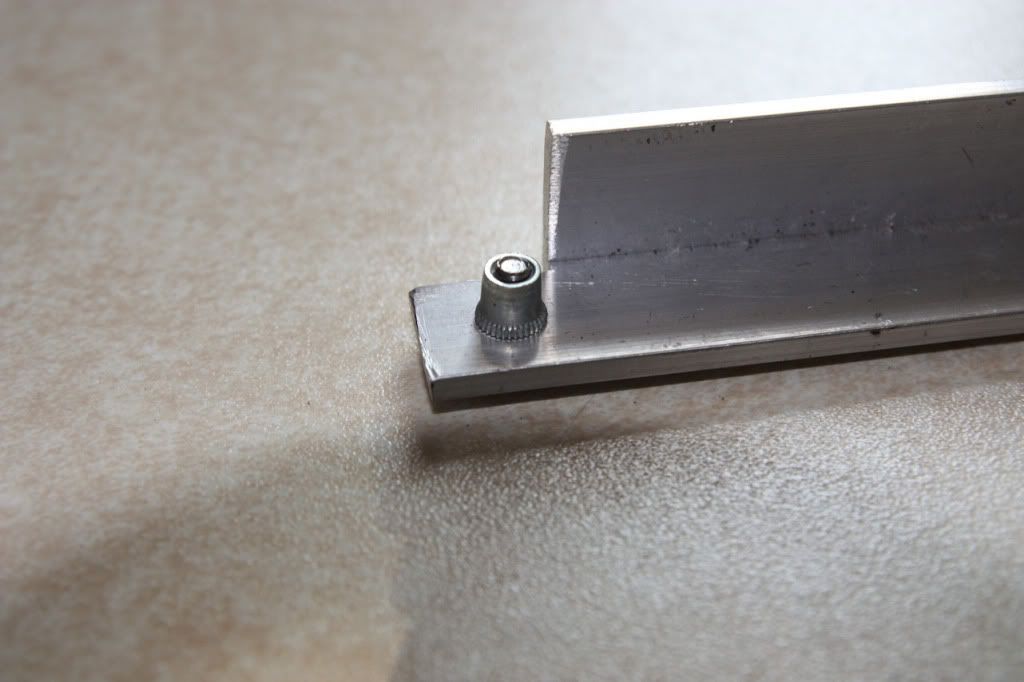

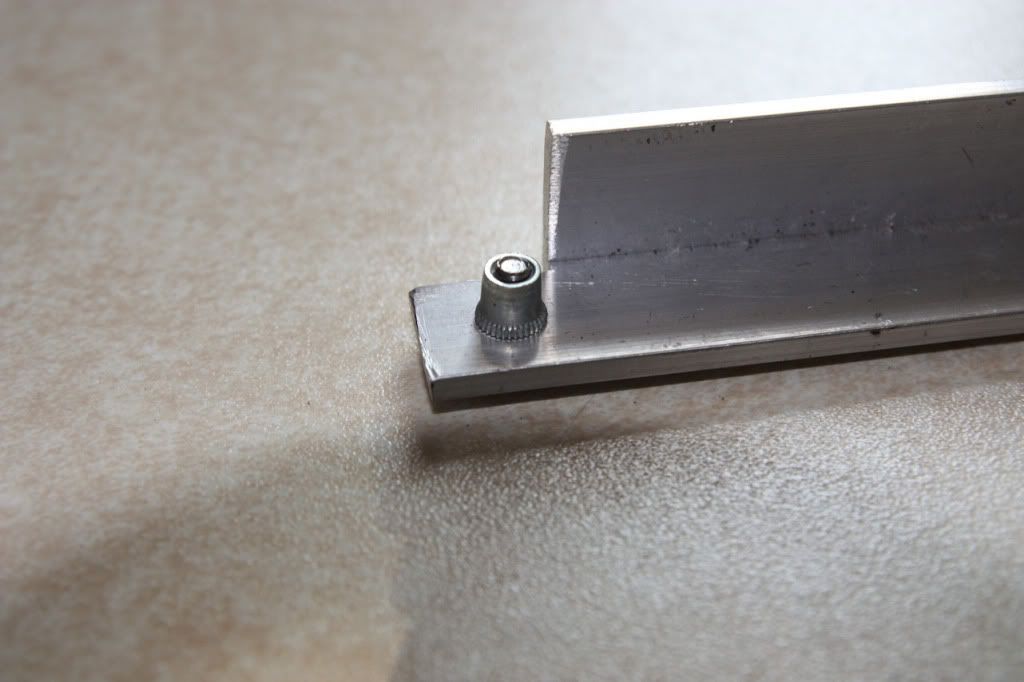

As I have been asked by a few people about the nut rivets I used. I thought I would give you all a more in-depth run down of what I have done to date:-

Firstly I placed the panel on top of the frame in the correct place

I then drilled a 4mm hole in the frame

To stop the panel from moving, I pop riveted the panel in place. (I did this in a few places)

I then drilled all the 4mm holes into the frame & drilled the heads of the pop rivets out.

The nut rivets that I used were 4mm thread with a counter sunk head (to give a flush finish on the frame)

I measured the outer diameter of the rivet to give me the correct size drill

I then drilled all the holes on the frame with a 5.93mm drill

To ensure the panels sit flush, a counter sinking tool was used

All the holes were then counter sunk.

If the counter sink is not deep enough, then the rivet sits high & not flush to the frame.

More material has to be removed

Now the rivet will sit flush

Screw the rivet nut onto the end of the 4mm insert for the rivet nut gun.

Put the rivet in the counter sunk hole & squeeze the handles together.

The nut is deformed underneath & the thread is in perfect condition.

Firstly I placed the panel on top of the frame in the correct place

I then drilled a 4mm hole in the frame

To stop the panel from moving, I pop riveted the panel in place. (I did this in a few places)

I then drilled all the 4mm holes into the frame & drilled the heads of the pop rivets out.

The nut rivets that I used were 4mm thread with a counter sunk head (to give a flush finish on the frame)

I measured the outer diameter of the rivet to give me the correct size drill

I then drilled all the holes on the frame with a 5.93mm drill

To ensure the panels sit flush, a counter sinking tool was used

All the holes were then counter sunk.

If the counter sink is not deep enough, then the rivet sits high & not flush to the frame.

More material has to be removed

Now the rivet will sit flush

Screw the rivet nut onto the end of the 4mm insert for the rivet nut gun.

Put the rivet in the counter sunk hole & squeeze the handles together.

The nut is deformed underneath & the thread is in perfect condition.

I then drilled all the holes on the frame with a 5.93mm drill

Where do you get one of those from? Is that a 6mm drill bit or is it 15/64th if such a drill exists?

Sounds like a lot of effort, but I guess it's to get a better look than pop rivets, which I completely understand. And given that they have a thread I assume that you'll be able take the panels off afterwards, which is clearly a very good thing.

Once again it all seems well thought out, as we're come to expect from a Piggin enterprise (the Stye, the Shelf and now the left-handed build..).

Yes, I have a 15/64th drill

(I have a full set of drills from 1/64th up to 1/4" in 1/64th increments)

I don't think you have to be that accurate, as a 6mm drill will do.

As for the effort, I did not want to drill & tap 80 holes in the frame.

Also, I can always drill out the rivet if the thread is ever damaged.

As for the panels, they will all be removable (the rear will be a little more difficult as the PSU will be attached)

"Well thought out" lol, Mrs Piggin would argue that nothing is well thought out but thanks M8 for the complement

(I have a full set of drills from 1/64th up to 1/4" in 1/64th increments)

I don't think you have to be that accurate, as a 6mm drill will do.

As for the effort, I did not want to drill & tap 80 holes in the frame.

Also, I can always drill out the rivet if the thread is ever damaged.

As for the panels, they will all be removable (the rear will be a little more difficult as the PSU will be attached)

"Well thought out" lol, Mrs Piggin would argue that nothing is well thought out but thanks M8 for the complement

As for the effort, I did not want to drill & tap 80 holes in the frame.

80!!! That does sound like a bit of overkill. I know it's too late now but I wonder if you only needed one per corner and one in the middle of each side (as opposed to the 2 you have). That would have saved 24 holes wouldn't it? And made it easier to remove a panel with only 8 screws to undo.

I assume that sliding panels would have been harder to manufacture, which is why you went for the totally screwed* in approach?

** By that I mean just using screws... or even bolts.

Last edited:

Soldato

- Joined

- 16 Nov 2010

- Posts

- 16,513

- Location

- Swimming in a lake

Can't be too much left to do now surely?

Guessing painting and stuff?

Secretly hoping there's quite a bit left because this has been a really good build log to watch so far!

kd

Guessing painting and stuff?

Secretly hoping there's quite a bit left because this has been a really good build log to watch so far!

kd

Simply an epic thread! I am hanging off the edge of my seat waiting for new pictures of this truly amazing and frankly awe inspiring build!

Stoner81.

Thanks Stoner81, I am very happy you are enjoying my build.

Hopefully more pictures very soon

80!!! That does sound like a bit of overkill. I know it's too late now but I wonder if you only needed one per corner and one in the middle of each side (as opposed to the 2 you have). That would have saved 24 holes wouldn't it? And made it easier to remove a panel with only 8 screws to undo.

I assume that sliding panels would have been harder to manufacture, which is why you went for the totally screwed* in approach?

** By that I mean just using screws... or even bolts.

John, I looked at using only 8 bolts per side as you suggested but decided to go with 12 as it looked better. Also the panels are very large & require a lot of holding on.

I also agree that it would have cut down on some of the labor time but the nut rivets are very easy to use & take very little time.

As for the sliding panels, they are not easy to make.

Can't be too much left to do now surely?

Guessing painting and stuff?

Secretly hoping there's quite a bit left because this has been a really good build log to watch so far!

kd

kd, I would not worry if I was you. lol

There is a lot of work still to do (motherboard tray, internal shelf, brackets, drive holders, wiring, fans, mounting equipment, piping up, fan grills, window & painting)

And that's what I can think of off the top of my head.

I think this build log will be around for some time to come.

I have just stumbled across this thread, almost by accident, and than just had to sit back and read all 8 pages of it!

It has to be one of the most interesting and entertaining 'stories' I have found for a long time, and I will make sure I 'bookmark' it now, so as to receive regular updates, as I have a feeling it will be one of those projects which will never be 100% completed, but will, like Topsy, just continue to grow and grow!

Hopefully both Mr and Mrs P. are now restored to full health again, and are not annoying each other too much!

I only wish I had the money, time and patience (and skills) to undertake such a project, but I know I never will... still, I do enjoy my own modest (by this standard anyway!) builds though.

Keep up the good work... and the regular updates!

It has to be one of the most interesting and entertaining 'stories' I have found for a long time, and I will make sure I 'bookmark' it now, so as to receive regular updates, as I have a feeling it will be one of those projects which will never be 100% completed, but will, like Topsy, just continue to grow and grow!

Hopefully both Mr and Mrs P. are now restored to full health again, and are not annoying each other too much!

I only wish I had the money, time and patience (and skills) to undertake such a project, but I know I never will... still, I do enjoy my own modest (by this standard anyway!) builds though.

Keep up the good work... and the regular updates!