Looking forward to seeing more, love the pinnacle, cant wait to work in it

lol. the 29th will soon come

Looking forward to seeing more, love the pinnacle, cant wait to work in it

Very interested to see how this turns out. Looks great so far

what about some ventilation fins like on old school lockers?!

maybe too industrial and not refined enough, but could look meaty!

i wonder how disruptive they would be, if they were all facing the same way without much surface between the gaps.... maybe could try and test it by blowing some smoke through a fan onto a mock up....

That would make my day seeing someone in my school locker with a PC fan and a 12V battery setting a piece of paper on fire!

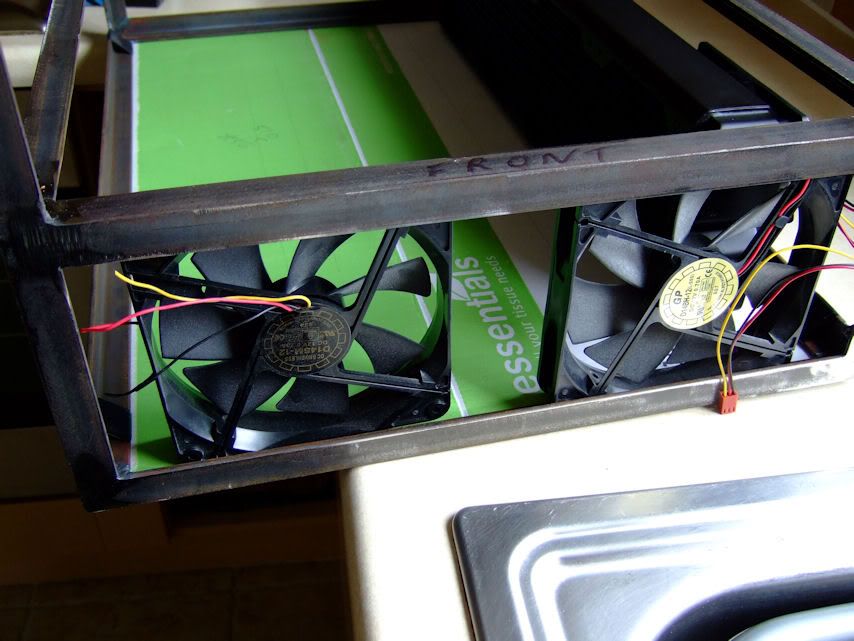

Wht the hell are you building.... Its a monster

Following this now, love builds from scratch especially when "old school" techniques are used. Got to say I'm one for throwing stuff together and see what it looks like

Keep up the good work mate.

I spent my teens putting my computer into various "custom" cases. Started off painting a gateway case black, then crammed everything into an old scanner so the window was the glass panel and then into one of those metal photography cases. Until I settled with modding a lian-li case.

However seeing your start has made me want to knock something up for scratch, and like yourself I've kept cages and motherboard trays over the years just for this sort of project

Again can't wait to see any updates on this.

Hi Piggin would you mind activating your trust and letting me know where you got the dense weave. i've tried a few that have claimed to be dense and aren't but that stuff looks the muts nuts

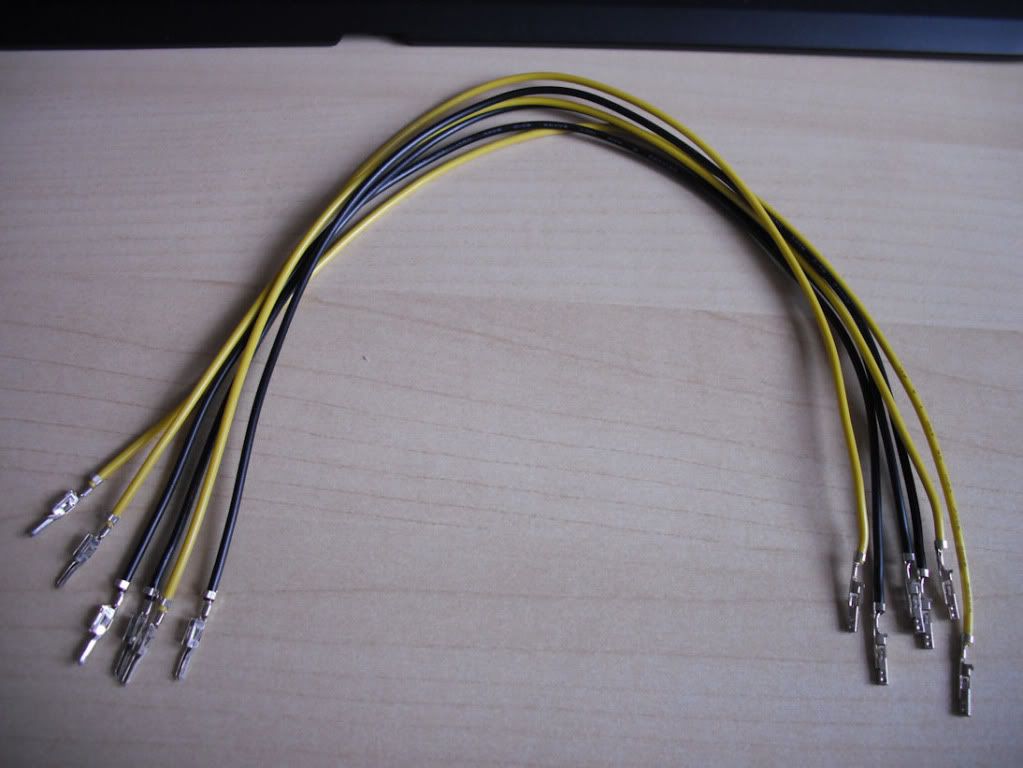

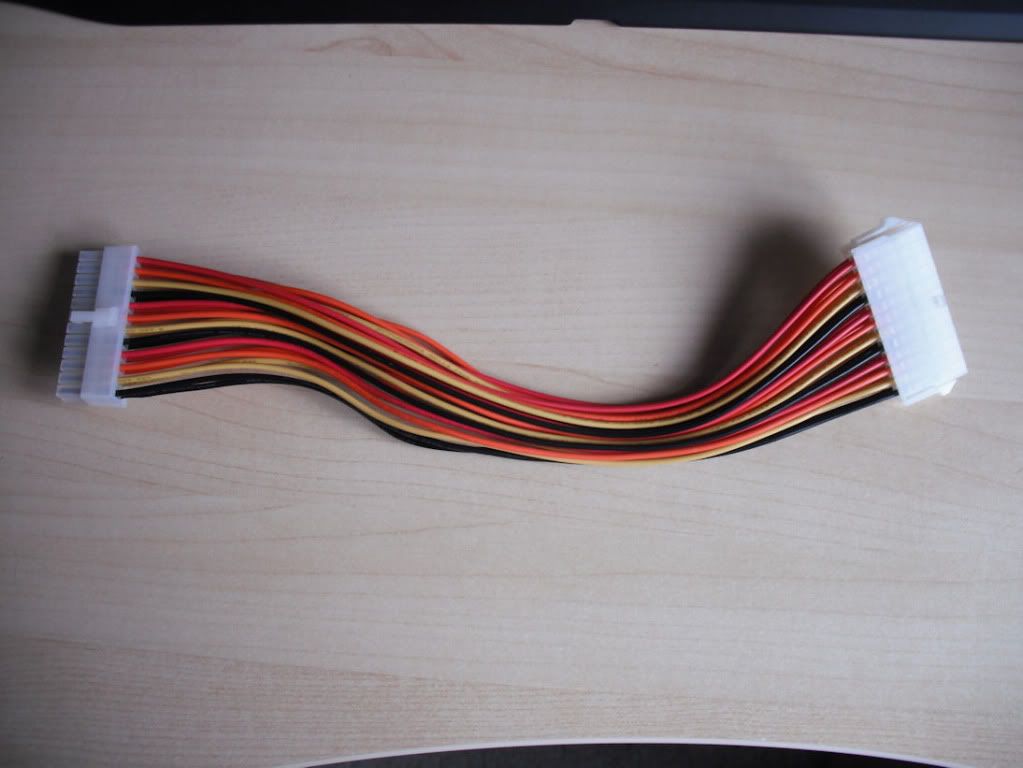

Really impressed by this build - Love the kit going into this build as much as I'm loving watching the case coming to life (so to speak lol)

I've spent so long looking through older threads of build logs that it's quite frustrating having to wait for updates now lol

Great job fella

*subscribed*

Cheers for the link Piggin. I've just ordered a shed load of the black in various sizes. Should see me through a few mods.

Other factors have to come into ofcourse but I would say continue if you can. It is something different from the norm to see someone building a case themselves. Looking good so far though

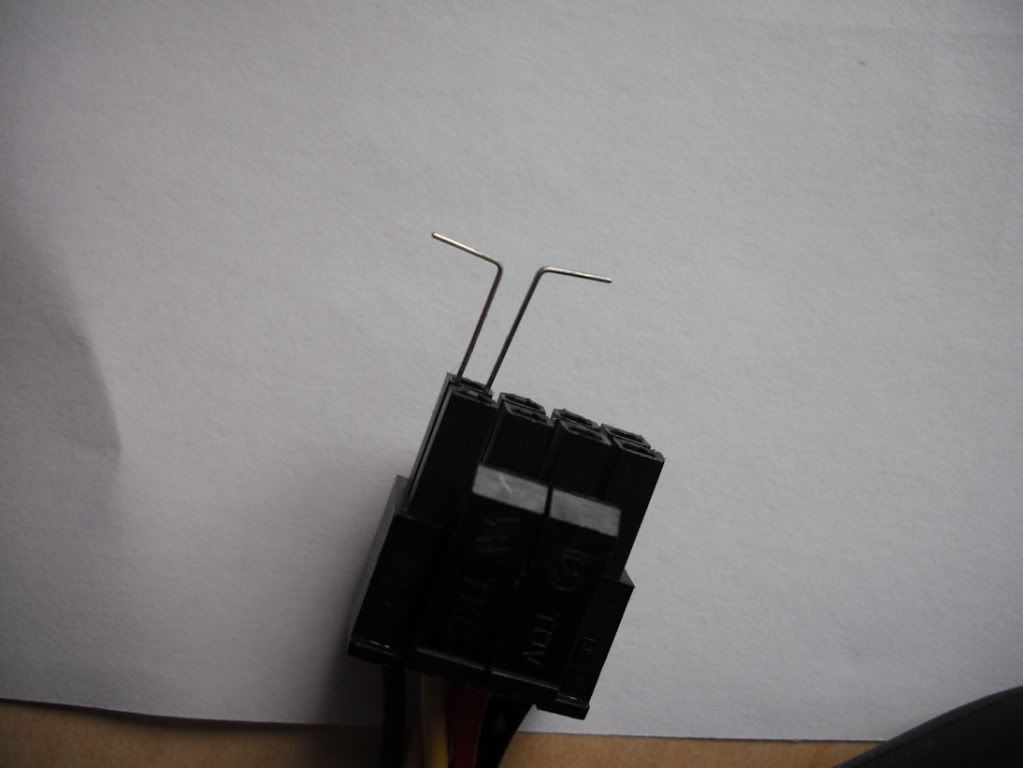

Ohthat is a little more than a minor set back. Its doing it all the old fashioned way, if you had of done all the cad modelling then it would be fine

Always a let down when something like this happens but hopefully you can find a way round it

Well you seem to have everything you need. Nice monitor, once it's clean, I imagine your desk is going to look very nice indeed.

Me and you both, hurry up is needed. For me, it's mum and dad who ain't seeing the funny side. My dad bet me £100 yesterday that my build wouldn't be finished before christmasI'll show him!

Where are you planning on putting the beast? Under the table would be plain blasphemy, and madness...

Anyway, any idea on what kind of design you are looking at? Clean, military, windowed etc? When I see the the framework all I can think of is that Wolfenstein mod from years ago, I liked that one a few years ago. Are you looking at extremes such as digital camo or stencil spay paint or more subtle effects?

Can't wait to see how this pans out. I think you should get some of the 'billet' rad grills from the American modding shop for the rads to give it a real solid effect. Personally, I wouldn't go for an over-industrial effect, but there's nothing I like more than a solid, metal case!

I did include a pic but it had a logo so I wasn't sure if they were a competitor or not.