I did a refresh of my loop over the weekend:

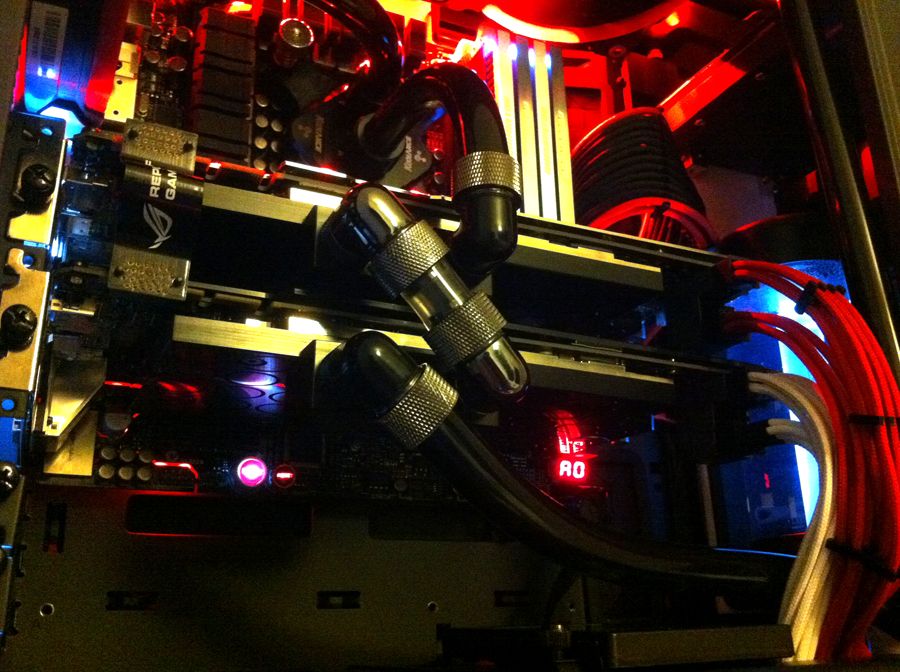

Fresh tubing

New fittings

Relocated the reservoir

Installed an EX pump top on my D5 and property bolted it to the case

When I took my radiator out of cleaning I found that it was actually leaking. It was an XSPX EX240 and I had been using it for around 3 years. I was quite surprised and disappointed. The paint had come away slightly at both ends of the radiator revealing the metal beneath. Both areas looked damp. And after wiping dry they would soon become wet again when I swished water around the radiator.

I had to make an emergency visit to OCers for a replacement.

Fresh tubing

New fittings

Relocated the reservoir

Installed an EX pump top on my D5 and property bolted it to the case

When I took my radiator out of cleaning I found that it was actually leaking. It was an XSPX EX240 and I had been using it for around 3 years. I was quite surprised and disappointed. The paint had come away slightly at both ends of the radiator revealing the metal beneath. Both areas looked damp. And after wiping dry they would soon become wet again when I swished water around the radiator.

I had to make an emergency visit to OCers for a replacement.

. Are they the new compression multi links? I am in the process of getting bits together for my acrylic build and will be using straight acrylic using just the normal bitspower multi links.

. Are they the new compression multi links? I am in the process of getting bits together for my acrylic build and will be using straight acrylic using just the normal bitspower multi links.