- Joined

- 20 Oct 2002

- Posts

- 17,178

- Location

- In a house

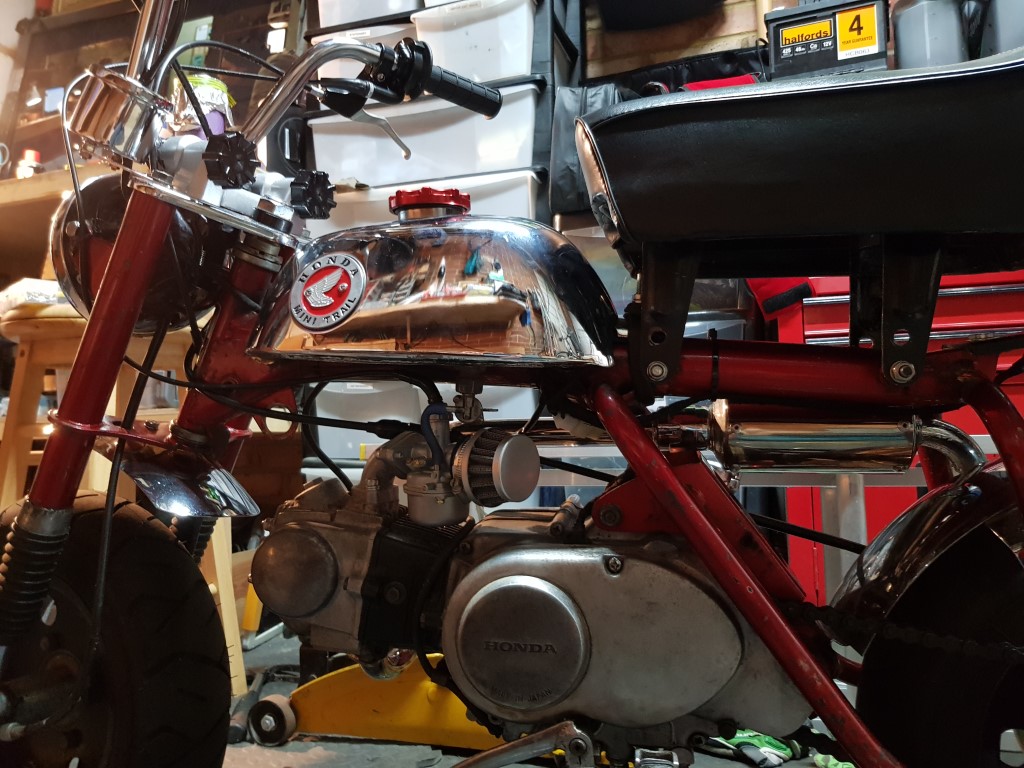

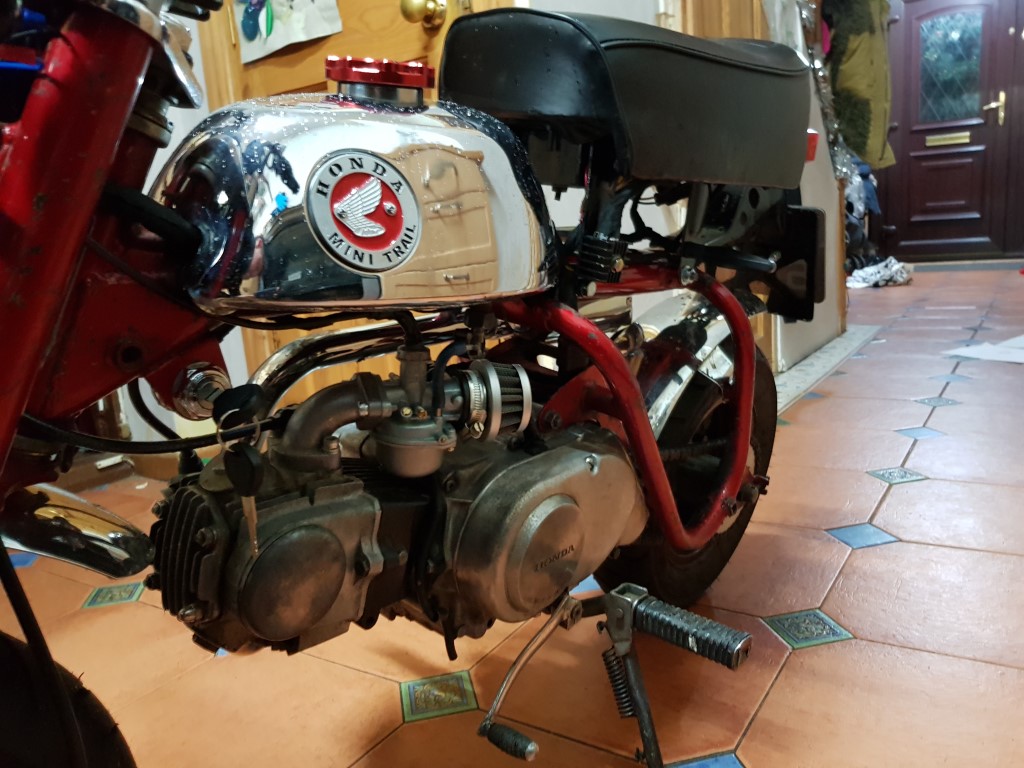

So after some discussions with the vendor and fitting a rev counter for testing on some longer trips, I am almost certain this lack of speed is down to gearing. (27mph at the 8500 rpm in third)

Going to try a few larger front sockets. Standard is 13t, so going to get a 14t and 15t to try ASAP.

Yup, just ordered a 15t front and 31t rear. Should get me about 30% increased top speed, and a corresponding lower acceleration. But as first gear is almost useless, I hope this will be fine, and just make it seem a bit longer!

Should be able to get away with the chain already in use on the bike for testing purposes.

Wow, that's quite a difference @Diddums with the 2 stroke upgrade! However, I have spoken to other owners of this kit, and they are all happy with it. So it's likely to be something specific to mine.

Going to try a few larger front sockets. Standard is 13t, so going to get a 14t and 15t to try ASAP.

Yup, just ordered a 15t front and 31t rear. Should get me about 30% increased top speed, and a corresponding lower acceleration. But as first gear is almost useless, I hope this will be fine, and just make it seem a bit longer!

Should be able to get away with the chain already in use on the bike for testing purposes.

Wow, that's quite a difference @Diddums with the 2 stroke upgrade! However, I have spoken to other owners of this kit, and they are all happy with it. So it's likely to be something specific to mine.

Last edited:

I tried epoxy, and superglue to bring it back, but it just looked terrible. So i ordered in a part from the Philippines and it looked a lot better! here is the original lens before I killed it

I tried epoxy, and superglue to bring it back, but it just looked terrible. So i ordered in a part from the Philippines and it looked a lot better! here is the original lens before I killed it