Cheers Mark

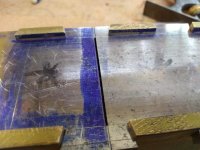

No, the plane will have a fixed sole so no adjustment. What set Mitre planes apart from other planes was the incredibly small mouth opening.

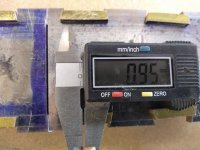

The mouth on a recent Stanley or Record plane might be 5-6mm wide if not more, the mouth on a mitre plane is only 1-2mm. Typically mitre planes where used to take very fine final shavings or plane end grain.

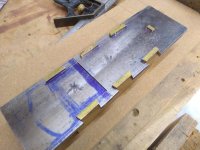

To get a mouth this tight by hand you can really only achieve it by making the sole in two pieces. Traditionally there was a tongue and groove joint to align the two pieces but I thought a V joint would be easier, I was wrong

Engineering is appealing to me too, I'm a furniture maker but like to try my hand at different things, I just enjoy making things I guess.

Can't go wrong with a well looked after "older" Stanley plane.

Like you say the new stuff is probably made in china and not any where near as good quality.

I'd take a good condition second hand plane over a brand new one any day, Unless it's a premium maker like Clifton, Veritas, Lie Nielsen etc.

After that you're moving into bespoke planes like Lazarus, Holtey, Sauer & Steiner, Oliver sparks, etc

But you need very deep pockets for one of those!

Is that so you can adjust the front mouth?

No, the plane will have a fixed sole so no adjustment. What set Mitre planes apart from other planes was the incredibly small mouth opening.

The mouth on a recent Stanley or Record plane might be 5-6mm wide if not more, the mouth on a mitre plane is only 1-2mm. Typically mitre planes where used to take very fine final shavings or plane end grain.

To get a mouth this tight by hand you can really only achieve it by making the sole in two pieces. Traditionally there was a tongue and groove joint to align the two pieces but I thought a V joint would be easier, I was wrong

Engineering is appealing to me too, I'm a furniture maker but like to try my hand at different things, I just enjoy making things I guess.

Can't go wrong with a well looked after "older" Stanley plane.

Like you say the new stuff is probably made in china and not any where near as good quality.

I'd take a good condition second hand plane over a brand new one any day, Unless it's a premium maker like Clifton, Veritas, Lie Nielsen etc.

After that you're moving into bespoke planes like Lazarus, Holtey, Sauer & Steiner, Oliver sparks, etc

But you need very deep pockets for one of those!