Blanking Plates

What is some good news is that I've finally finished the core construction of the case. Still lots of new holes and whatnot to put in for tube runs, mounting points, etc, but it's nice that the procrastination is done with and I can stop faffing about.

To keep the stock look going I wanted to blank off the front half of the radiator area underneath the glass panels, but I also need easy access to that area for working with tubing, running cables and the DDC cooling fan. So the idea is to have 2 plates attached with thumb screws that are folded around the upright and horizontal parts of the case body. Unfortunately previous bending attempts on tiny flaps of alu met with the same issues I had on the larger case parts; try to bend too wide a piece and the bend radius shoots up.

Let's try perforating the fold lines then and see if we can lessen the resistance.

Fold lines marked and center punched

Drilled (forgot to switch to a 1mm bit before starting

)

Lined up in the folder

And folded up, with no real improvement in bend radius down the length.

I guess ultimately I'm not reducing the amount of material to be folded with such small holes. Ah well, no big. Looks fine once the holes are filled and put in place.

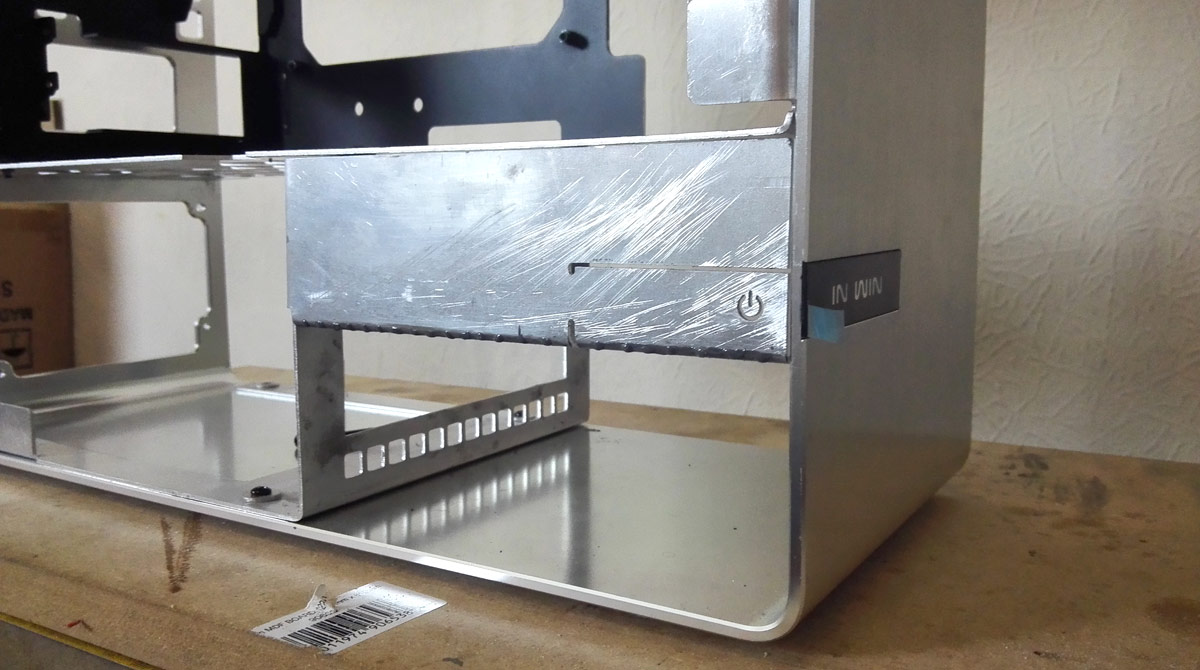

Annoyingly though it looks like something got into my bag of smaller metal bits and scratched them during a recent tidy up. Should buff out no problem before powder coating, but it's an extra job.

I have a choice of panel for the front side:

Both replicate the stock 901's power button in that it's a springy tongue of material resting against a tactile switch. I'm going initially for the version with a power icon cut into it so I can try and light it up.

For this to work as intended, I need to slice off a bit of the new bodywork to give an inset for the plate to press into.

It's about 3mm deep and angled up to the "hinge" on the blanking plate.

So when the plate is in position...quick balancing act!

The upper half of the plate is flush against the bodywork, and the folded tab on the far side is pushed over 90 degrees to give a tight grip. The lower half then can be pressed in and trigger a tactile switch set up behind it.

In place

Minor disappointment in that with all the bending issues I've had all dimensions are just a tiny bit off what was originally planned, so the power button strip is now about 3mm lower than it should be and no longer lines up with the In Win logo on the front of the case. I really hope I can buff those scratches out without resorting to filler

they're not actually deep so fingers-crossed smoothing them off and then powder coating will hide it.

I might have spares though, assuming they're not scratched up too. Worst-case scenario I just remake them, but I'm inclined to just use alu angle so I don't have to worry about folding it. The thumbscrew tab bends nicely, and I can just round off the sharp angle edge. An option...

Either which way, with this bit done and the lower portions finally supported, threaded (again) and all screwed together, the actual reconstruction is done. Finally. Hurrah.

but hopefully I'll have something fun to report on soon.

but hopefully I'll have something fun to report on soon. but hopefully I'll have something fun to report on soon.

but hopefully I'll have something fun to report on soon.

Have you effectively created low-profile steel nuts? That maybe sit in the aluminium's hole with a flange to stop it pulling through?

Have you effectively created low-profile steel nuts? That maybe sit in the aluminium's hole with a flange to stop it pulling through?

they're not actually deep so fingers-crossed smoothing them off and then powder coating will hide it.

they're not actually deep so fingers-crossed smoothing them off and then powder coating will hide it.