They go to OEM’s first for testing/validation typically 6-12 months before retail.

If they aren't out, they aren't out, and desktop chips also go out for validation.

Being able to make ANY chips and being able to release to ship for revenue are entirely different things. You can make a run of chips with a 3% yield, get 50 working chips from several wafers and send them out to OEMs, that doesn't mean they can or will ship at that point.

Server only came 'first' when desktop and server used the exact same chips and there wasn't any real die size difference. IE if Intel had a P4 they used for both desktop and server, the exact same chip, why wouldn't they sell it first for server. When server chips started to be completely different and much larger, they don't come first and haven't for many generations. Not even close to coming first.

Zen 2 is going to be different simply because they are using the same chiplets and again with the same chips at the same size, the most important market money wise comes first. This would likely not be the case if the i/o die was made on 7nm and most certainly wouldn't be true if it was monolithic.

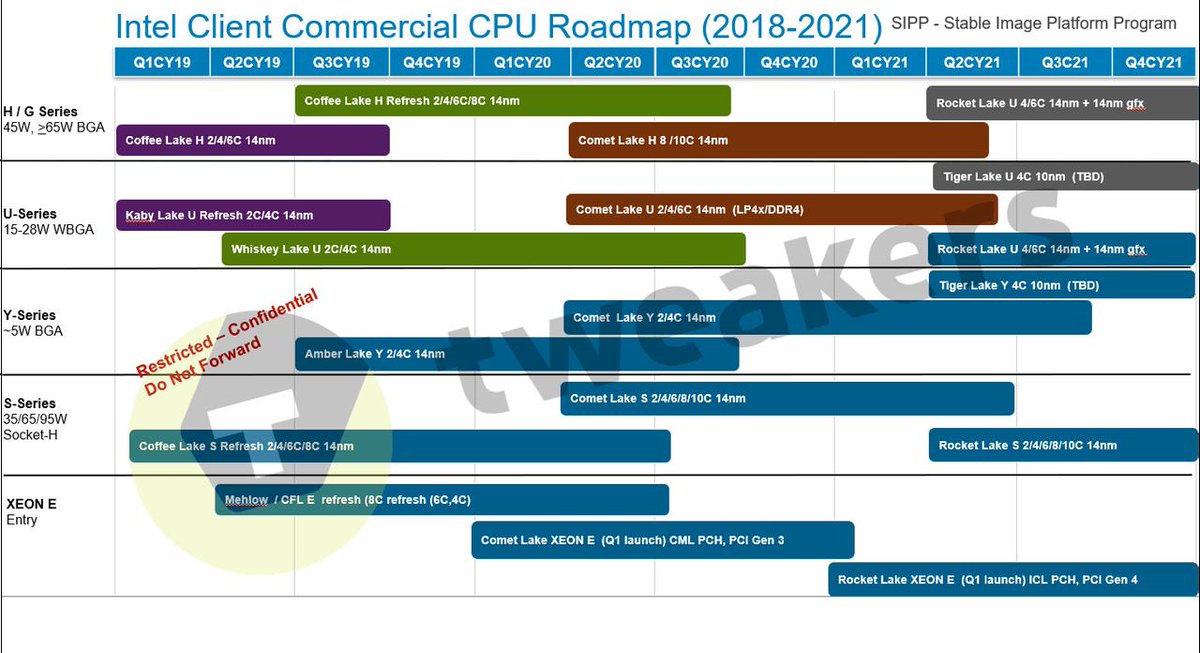

10nm has already 'launched' and the first chips on show were low yield dual core parts, 10nm dual/quad core mobile low power chips is what Intel is aiming for in late 2019, sounds like it will probably be several months into 2020 before we get desktop parts which are probably in the 120-150mm^2 range and from what we've seen of OEM leaks in past days, 14nm Cooperlake server is only hitting volume late 2019/early 2020 and icelake server is likely going to be Q3/q4 2020.

Process nodes are simple, yields are defined by defect rate and die size. With the same defect rate, which is down to the node, then yields go down exponentially with die size. <100mm^2 quad core (on 10nm, dual core on 14nm) will always have higher yields than a 100-200mm^2 die, which will always have a higher yield than 300-400mm^2 dies and so on and so on.

Early on a node when yields are worse and defect rate is higher profit on exceptionally low yield larger dies aren't actually financially viable. There is little point selling a product that both has little margin due to low yields and kills demand for existing chips but you can't produce in volume because of again, the low yields.