Picked up the car from Matt at Mprove today after it had it week long boot repair.

Here are some photos Matt took whilst performing the repair, re-inforcement plates and resin injection.

First of all how the car looks with the entire rear removed from the car:-

THE CRACKS!

The first image is the rear passenger side bush and it is common that they crack along where the body angles and as can be seen my car has a small crack there. It is easy to see this without removing the entire rear subframe and was the reason for this job being done.

The second picture is far more worrying that is the front drivers side mounting and it is severely cracked, that was a ticking time bomb as the spotweld had clearly exploded and cracked in all directions and also where the bolts goes into the body work was cracking around it too.

Needless to say this repair was needed, they have seen far worse to the point where boot floors are more or less hanging out the car as this is a design floor in the E46 chassis, yes all E46 suffer from this, but more so M3's due to more stress being put on the chassis. You boys with superchargers and turbo's on your E46 are even more prone to this damage. Get the floor re-inforced!

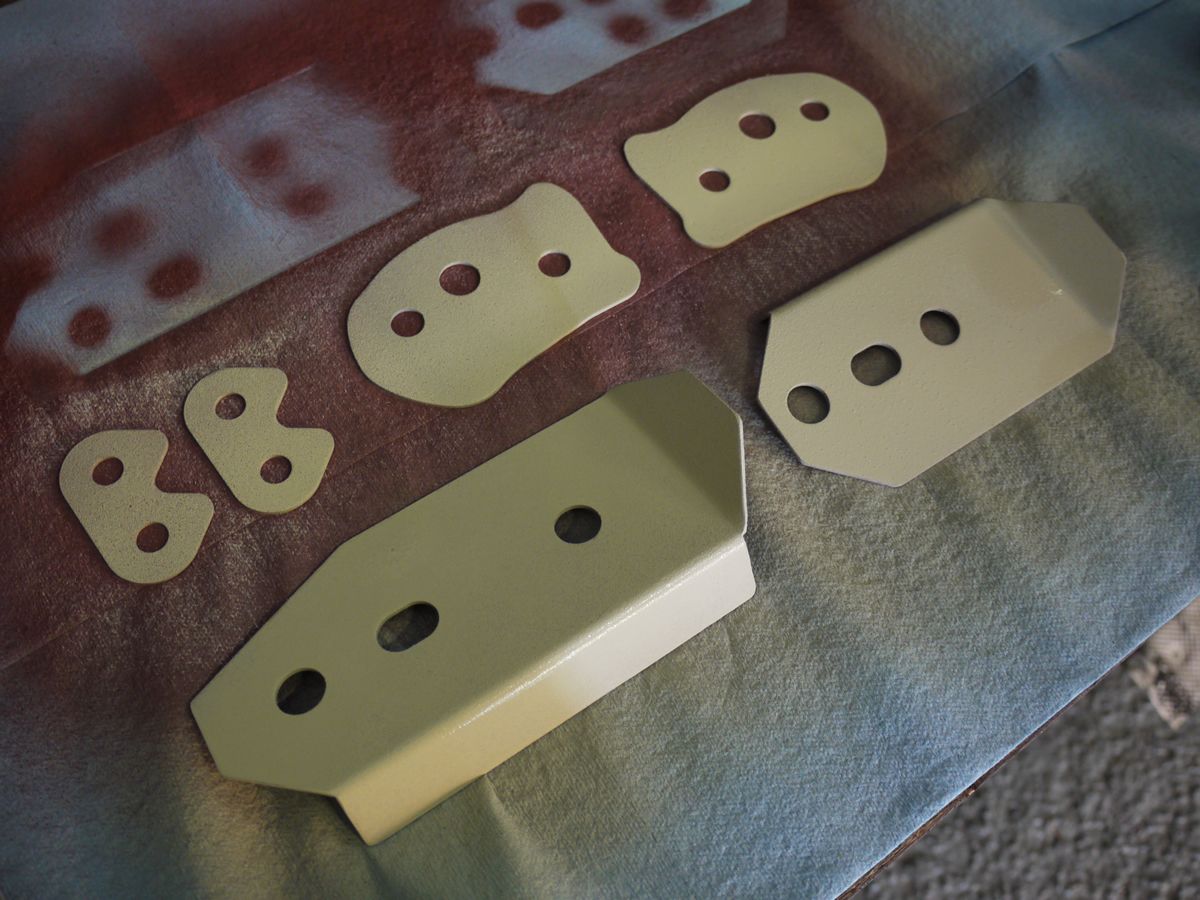

The cracks are repaired by drilling them at the ends to prevent them going further and then welding them back up. They are then plated with re-inforced plates and bonded into place which help to spread the stress more evenly and of course are re-inforced to prevent it from happening again.

Pictures of the plates and install:-

Matt then painted the whole underside of the car in BMW OEM Mushroom paint, to remain factory look and of course the underseal protection it gives to prevent rush etc.

Then all new subframe bushes, bolts and mounts are installed, I decided to stick with BMW OEM as I enjoy driving the car on the road so I don't want it to have loads of NVH or harshness. Pictures of bushes and subfram back on.

A nice picture of the whole rear end showing of the Eibach rear camber arms.

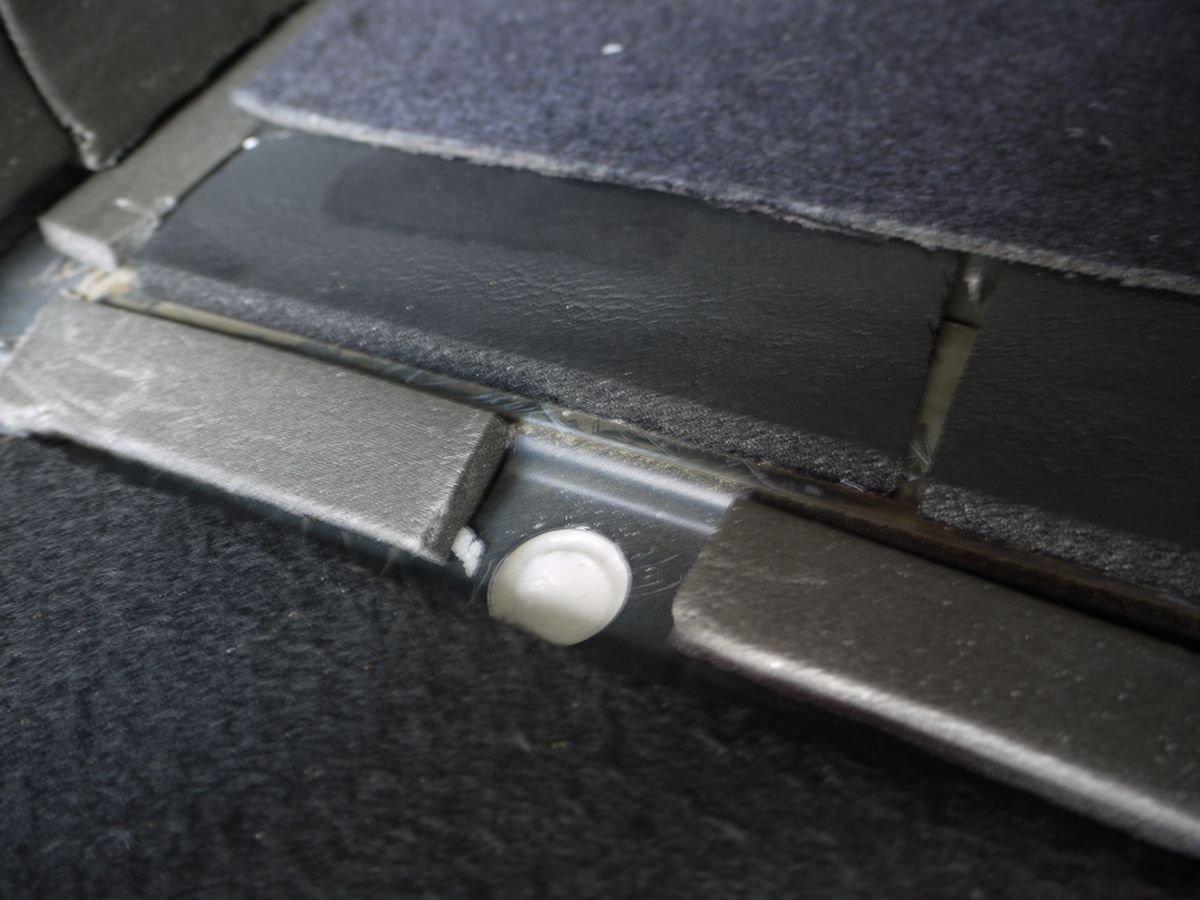

Then final procedure is to inject the rear end just as BMW would do with Resin to further strengthen the chassis, this stuff literally has no weight but is unbelievable strong.

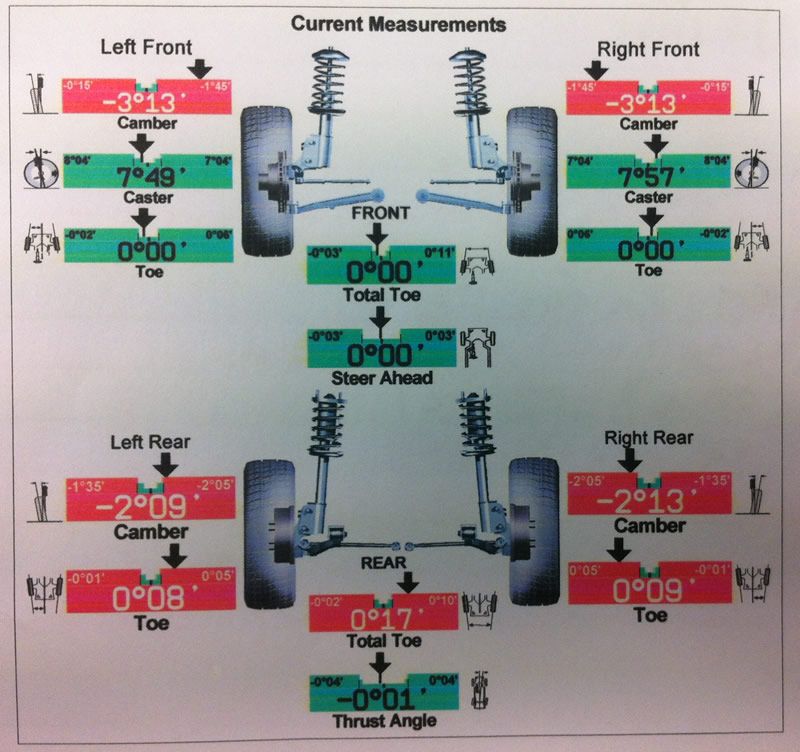

They re-installed and set the GEO to the same measurements they took before they dismantled everything. Only driven the car home on motorway so can't comment too much but the car seems quieter from the rear-end which is no doubt from the fresh bushes as the old ones were not looking so great, but after 100,000 miles you can't expect so.

I now have peace of mind, I can hoon it out of junctions, even use launch control and drive the car as hard as I dare too without worry of the boot falling out. Plus the car is completely re-bushed now front to rear including engine and transmission mounts.

Driving my car compared to my old CSL and mine is just in a different league and compared to other M3's I've driven mine is just so tight and a lot lot quicker, so I've done something right.

Whats left:-

Rear harness / cage

CSL roof, maybe......

That's it, I don't want to go supercharged or cams, the car drives so nice and has so much power/torque everywhere, I'd not want to spoil that drivability or the fact that the power to weight is pretty much perfect, any more and I'd spend more time controlling wheel spin than going forwards on the road. Could certainly take more power on track though with slicks for sure.