Hi there

Really time for an update:

For those who did not know, I converted to full CSL ECU running specification, map sensor etc. Drivability a vast improvement, basically just like a CSL, no hesitation or lack of power down low like Alpha-N can have, though mine was not so bad to be frank, but the CSL map is night and day better. I went with TTFS tune to the specifics of my car and did some data logging to improve it, in the end was a great running car which felt insanely fast on the road.

At the last dyno day I organised at OcUK the tuner did some live tuning on the dyno (via remote login) and fixed some over-fuelling issues and recommended we increase rpm to 8500rpm, stating it is perfectly safe. Got the fuelling spot on and car was running better than ever. Unfortunately 50-100 miles after the dyno the engine developed knocking, so I got RAC recovery.

So in short with the help of Andy (Powerstation) we diagnosed the engine had most likely spun a bearing but still had oil pressure so damage could be minimal. This was simply due to 8500rpm!! So keep your rev limiters stock guys!

So I decided to undertake an engine rebuild by myself in my driveway:

New parts arrived finally, took customs nearly two weeks:

Sump gasket

Rod bearings

ARP Bolts

KW front drop links (old ones had to much play)

Got the oil pump removed, used a cable tie to pull the chain together and then pushed the plastic tensioner out the way, it is reversed threaded but then the nut came off easily, also got myself some HEX sockets as the oil pump hex bolts are super tight. Oil pump and all return lines out the way:

The new bearings are coated and clearly packaged as lower and upper, a picture of a new bearing in end cap, you can clearly see the coating:

Now the fun started, first of all the upper bearings are so fiddly, not much room to get your hands up there, so takes a few attempts, luckily both the bearings and crank survived as I made sure to not touch them.

Plus Andy gave me an excellent idea of when end-cap is removed to then crank the engine until the piston is at the top and to then crank other direction bringing crank back down but leaving the piston dangling in the air, this worked very well.

OLD Bearings VS NEW!

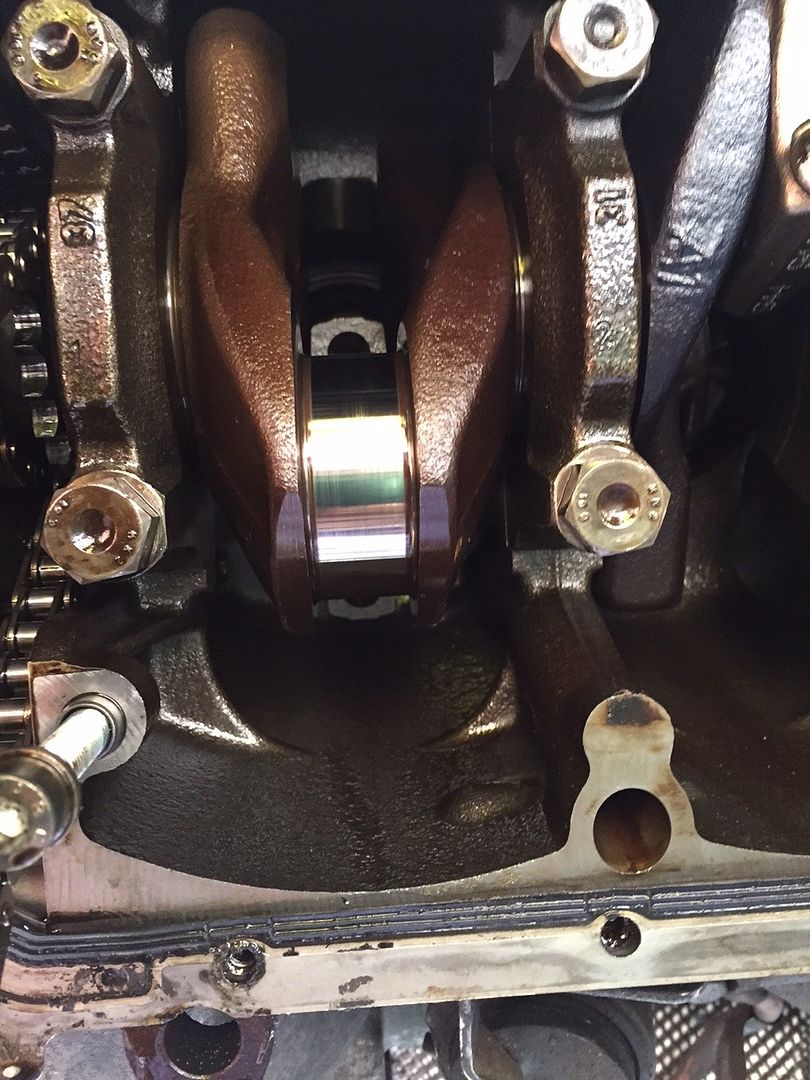

Anyway all the bearings were coming out and were all looking fine, I was beginning to worry that maybe I had another issue. But the last cylinder I did was number ONE.

As soon as I took the end cap of I noticed an issue, which was the end cap was quite a bit hard to get off and when it did come off the shell remained on the crank as did the rod side as well.

At this stage I thought none of the others did this and feared they were maybe welded to the crank but I touched them and they did move they just seem hydrolocked to the crank with oil, yes oil another good sign.

I got them off and well they tell a story:

This was close, very close!!!!

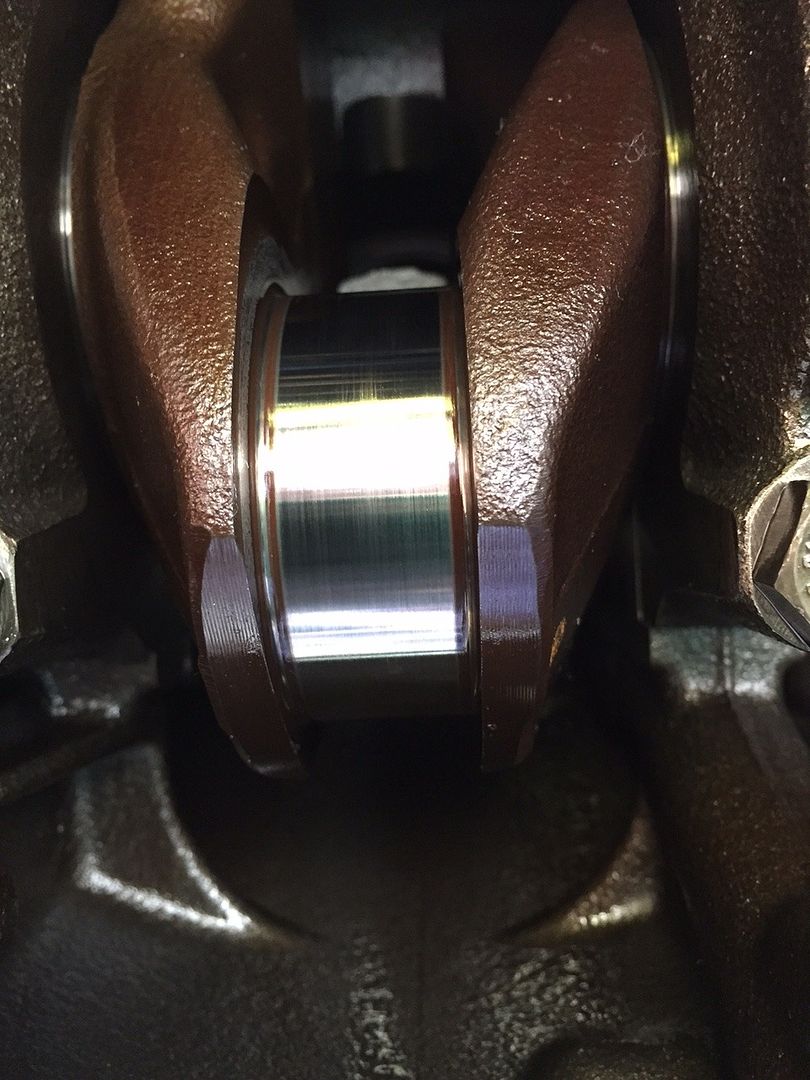

I inspected the crank and much to my relief it looked identical to how the crank looked at all the other cylinders, nice and shiny with no marks, scratches or pitting:

That's a relief!!

Car all back together with ARP bolts very easy tightening process of just tighten by hand and then torque to 70lb/ft.

Now to put it all back together.

Refit oil pump and chain

Refit oil pickup lines

Clean up sump and gasket area.

RTV sump, add gasket and more RTV.

Refit oil pan, making sure dip stick is partially inserted, this was a royal pain in the ass and a lot of swearing happened.

Tighten up sump starting from centre working outwards including all awkward bolts.

Refit power steering pump

Refit power steering pulley

Refit drive belt

Refit oil pipe and power steering brackets

Refit subframe, but do not tighten up much, say one turn.

Refit wishbones

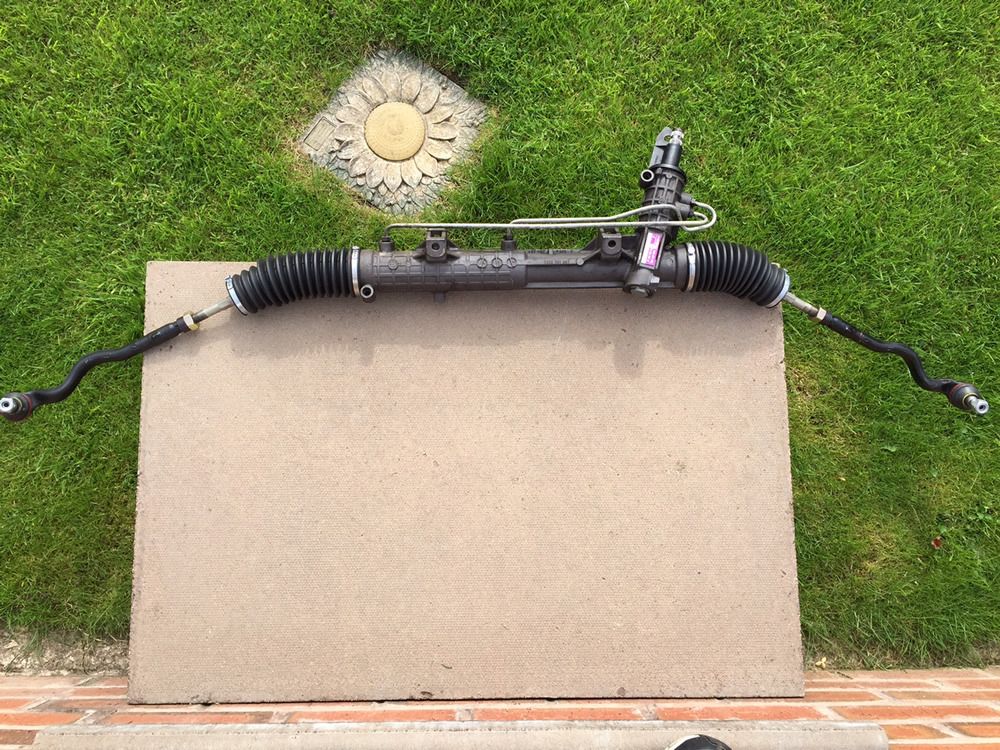

Refit steering rack, very tight hence reason for not tightening up subframe.

Now tighten up subframe bolts, steering rack bolts, steering guilbo, ensure wheels and steering wheel are centre before tightening.

Refit and tighten PS lines, make sure there is a washer either side

Refill power steering fluid, dextron 2/3 ATF/PS fluid for M3.

Tighten wishbones and track rod ends, use a pumpkin jack to prevent nut from just spinning.

Check oil return lines, oil level sensor, headlight sensor/levelling and any other plugs are all connected and re-check all bolts.

Fill with 7l 5W-30 running in oil.

Leave plugs and coils out, crank the engine 5-6 times for 5-8s to build oil pressure and check oil level.

Install plugs and coils.

Start the engine, oil pressure light should go out within 5s, turn steering wheel left to right to flush air out of PS system and leave to idle until warm (80c) oil temp and then give some gentle revs. Once 30 mins passes shut off and drain oil and remove filter for inspection.

If all OK refill with correct Castrol 10W-60

Refit chassis brace, all undertrays, air box, pollen housing, rocker cover, strut brace etc. and check oil level.

Test drive.

Probably missed loads.

The noise myself and others heard in the car park has gone, even after an hours drive so oil upto around 90c, did not get over 100c as keeping revs under 5500rpm but car sounds healthy and is driving fine.

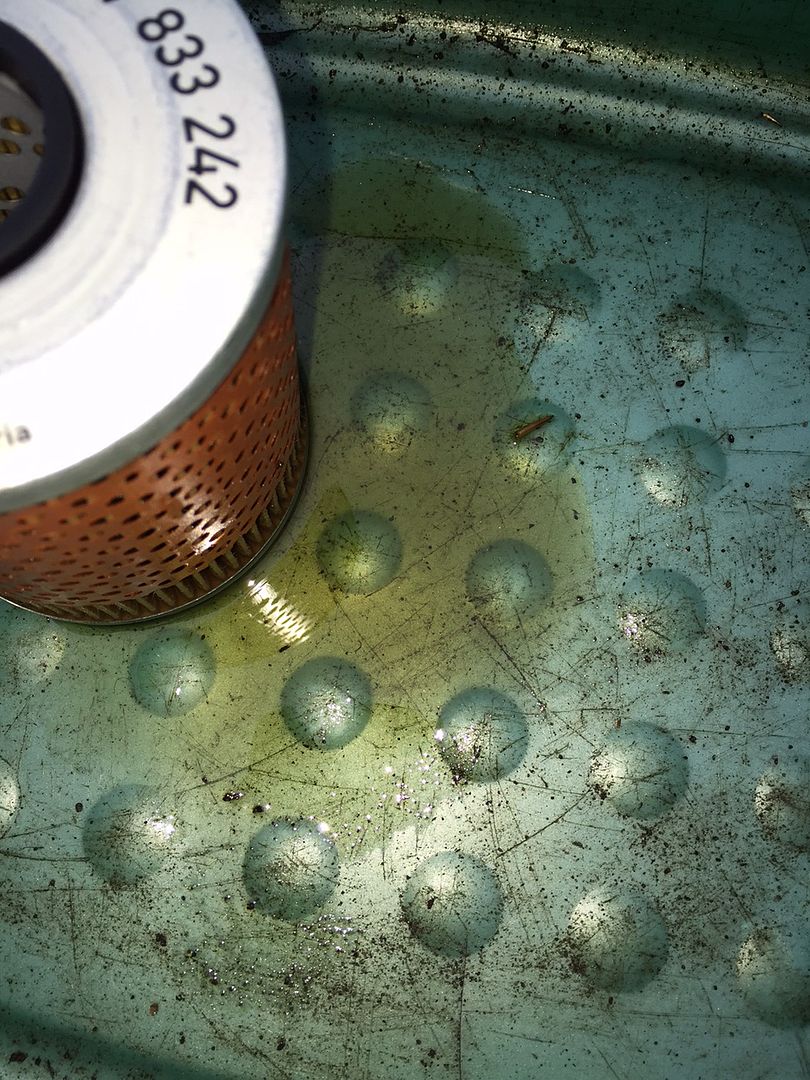

The oil from the filter from running in did seems to have a little debris but very hard to tell whereas before it was very clear, but this I suspect is what was left in the system, couple of picture:

Hopefully that is the last of it, but shall check the current filter in a couple of days to see if anything is in that one, fingers crossed.

It's good to have the car up and running again, drives superb, sounds great with no knocks, but only driven for an hour so far.

I've always being quite willing to work on my own cars, but not done anything major like this since I super charged the Mustang. I've learned a lot completely dissembling the front end of the car and opening up the engine. Quite enjoyed it but hope I don't have to do it again.

Finally a picture of some green from when it was all back together:

After 500 miles running in

500 miles running in done so far, so last night I dropped the oil, absolutely zero particles in the oil and the oil was still clean and no odd smells of fuel or burn.

Opened up the filter and to me it looked fine far far less copper in it than the initial 40 minute engine run-in I did, infact practically zero copper particles in the filter and only the odd carbon deposit. Took it to local engine builders and both same comment, looks absolute spot on, nothing to worry about.

The photo is near on useless and it makes it look like it is full of shiny particles but its just the filter material, so pretty pointless in posting, but hey ho posted it anyway.

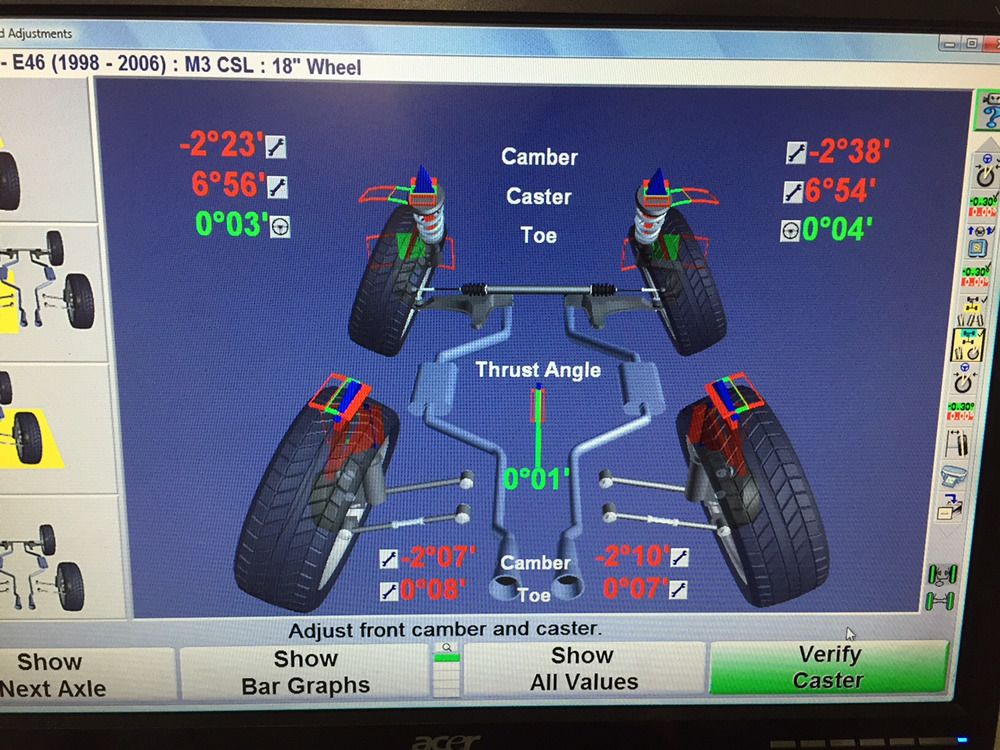

Had the alignment checked and all bolts re-checked, alignment was spot on, had not gone out whatsoever so I got it absolute 100% correct the way I dismantled the car, very happy.

Finally some green!

All the above I actually did months ago, the car has done well over 2000 miles now, it feels the strongest it has ever being. Apart from this I have not really done much at all with the car though apart from just drive it. So seems I successfully rebuit my engine and did a good job, still running fine and zero oil leaks.

Actually since June things have being pretty crazy, my father passed away and well I've simply being enjoying life and having great fun overseas. I am off overseas again next week for a few weeks again.

But tomorrow I shall be doing some work on the M3, namely a purple rack (AKA CSL ratio steering rack) and changing the oil to check on it. So will make an update hopefully, but not really planning any track work now this year, like I say am spending way to much time overseas enjoying myself so car has kind of taken a sidestep and just being used as a daily and weekend toy.