tonyyeb said:Get on with it

Yes Sir!

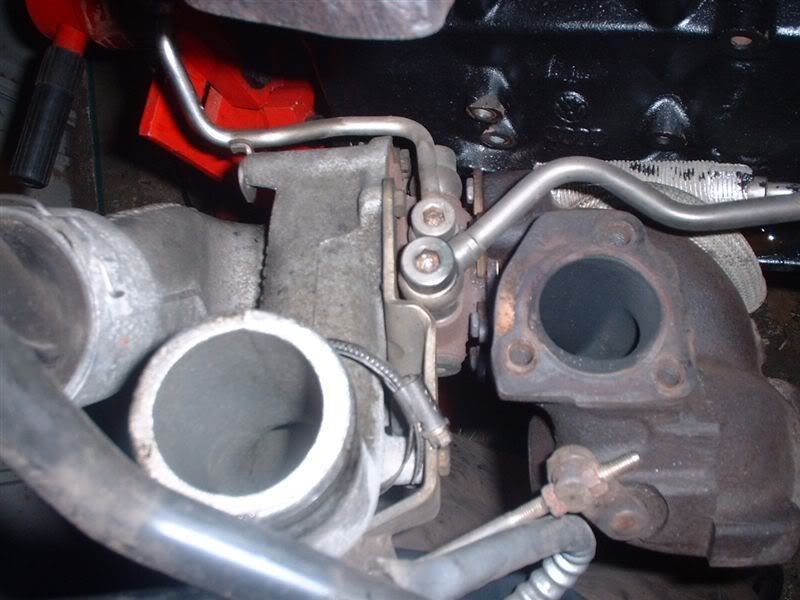

Removed the old turbo from the leon engine tonight:

Before, old rusted small thing!

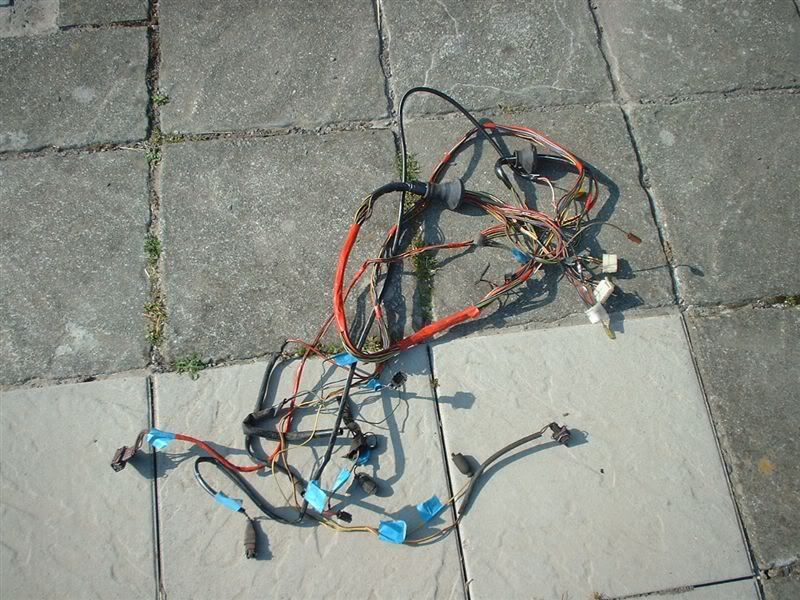

Oil and water pipes that needed to be removed

New small shiny turbo in place, excuse the smudge must have got some oil on the camera!

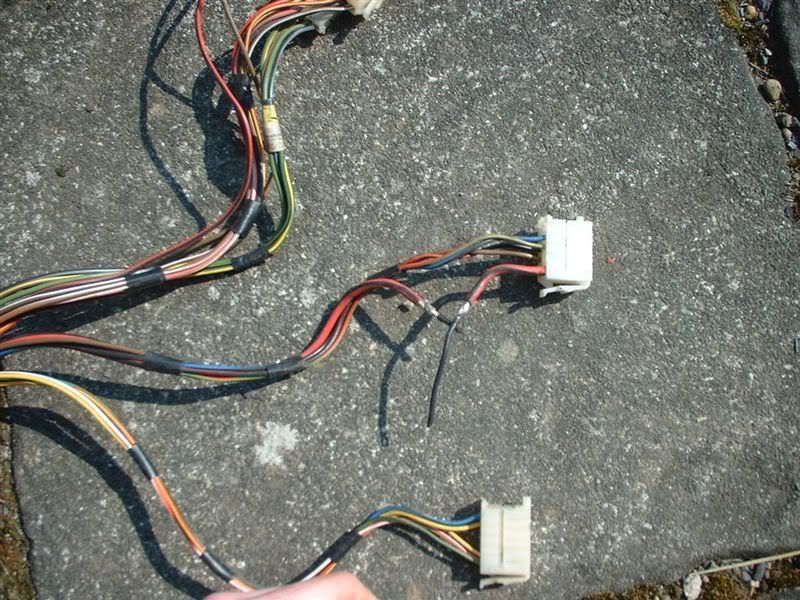

Whilst *gently* tapping the intake pipe back in place I managed to do this

Will have to find another one monday or make an alternative out of silicone pipes or similar. Not bad thats the first breakage in this project!

Last edited:

( I dont think anyone is going to get the nose thing

( I dont think anyone is going to get the nose thing