Hi there

Well today has being a long day, 8am start, 9pm finish.

Started with:

Remove front subframe

Remove oil pan

Install new ARP bolts and torque to 70lb/ft

Refit oil pump and chain

Refit oil pickup lines

Clean up sump and gasket area.

RTV sump, add gasket and more RTV.

Refit oil pan, making sure dip stick is partially inserted, this was a royal pain in the ass and a lot of swearing happened.

Tighten up sump starting from centre working outwards including all awkward bolts.

Refit power steering pump

Refit power steering pulley

Refit drive belt

Refit oil pipe and power steering brackets

Refit subframe, but do not tighten up much, say one turn.

Refit wishbones

Refit steering rack, very tight hence reason for not tightening up subframe.

Now tighten up subframe bolts, steering rack bolts, steering guilbo, ensure wheels and steering wheel are centre before tightening.

Refit and tighten PS lines, make sure there is a washer either side

Refill power steering fluid, dextron 2/3 ATF/PS fluid for M3.

Tighten wishbones and track rod ends, use a pumpkin jack to prevent nut from just spinning.

Check oil return lines, oil level sensor, headlight sensor/levelling and any other plugs are all connected and re-check all bolts.

Fill with 7l 5W-30 running in oil.

Leave plugs and coils out, crank the engine 5-6 times for 5-8s to build oil pressure and check oil level.

Install plugs and coils.

Start the engine, oil pressure light should go out within 5s, turn steering wheel left to right to flush air out of PS system and leave to idle until warm (80c) oil temp and then give some gentle revs. Once 30 mins passes shut off and drain oil and remove filter for inspection.

If all OK refill with correct Castrol 10W-60

Refit chassis brace, all undertrays, air box, pollen housing, rocker cover, strut brace etc. and check oil level.

Test drive.

Probably missed loads.

The noise myself and others heard in the car park has gone, even after an hours drive so oil upto around 90c, did not get over 100c as keeping revs under 5500rpm but car sounds healthy and is driving fine.

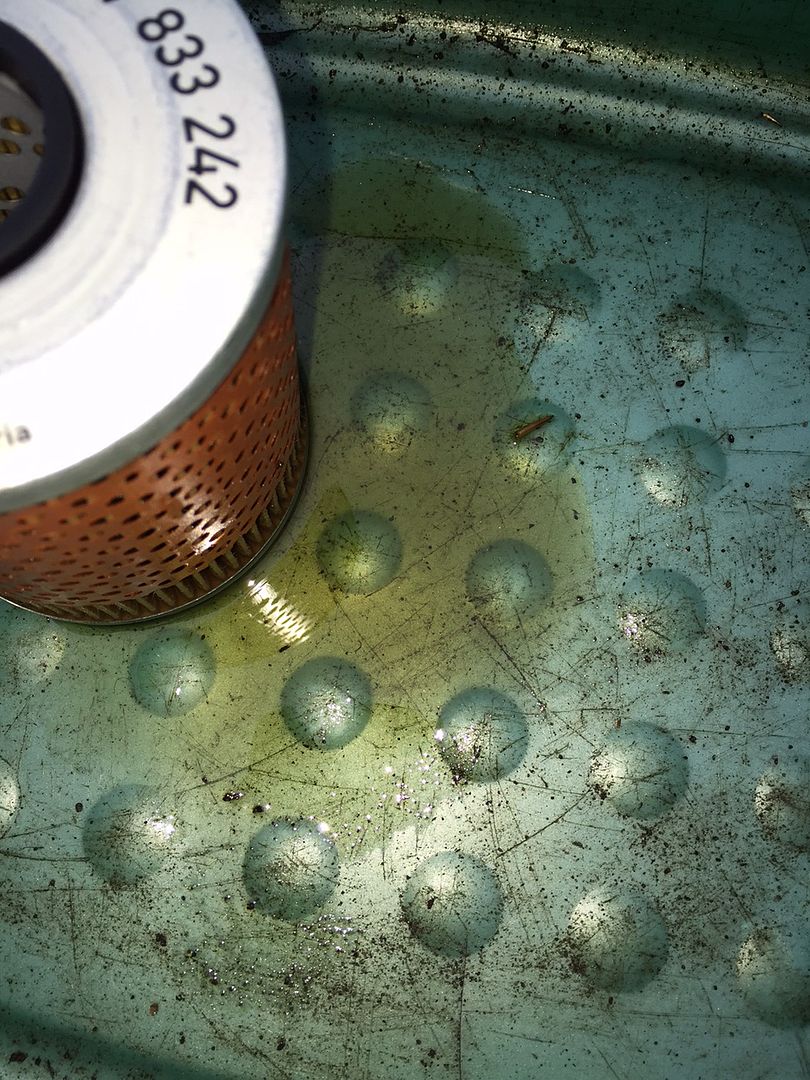

The oil from the filter from running in did seems to have a little debris but very hard to tell whereas before it was very clear, but this I suspect is what was left in the system, couple of picture:

Hopefully that is the last of it, but shall check the current filter in a couple of days to see if anything is in that one, fingers crossed.

It's good to have the car up and running again, drives superb, sounds great with no knocks, but only driven for an hour so far.

I've always being quite willing to work on my own cars, but not done anything major like this since I super charged the Mustang. I've learned a lot completely dissembling the front end of the car and opening up the engine. Quite enjoyed it but hope I don't have to do it again.

Finally a picture of some green from when it was all back together:

Will take the car to a couple of mates garages tomorrow who both build engines for them to have a listen, check the old shells out and inspect the filter in the car to see if they think it's all healthy.