Hi there

New parts arrived finally, took customs nearly two weeks:

Sump gasket

Rod bearings

Main bearings

ARP Bolts

KW front drop links (old ones had to much play)

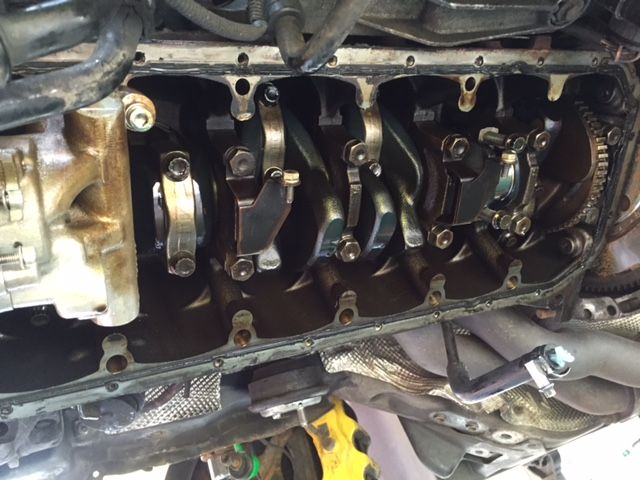

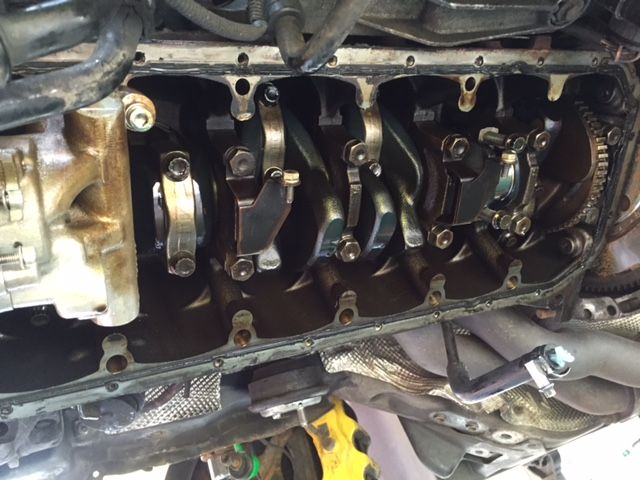

Got the oil pump removed, used a cable tie to pull the chain together and then pushed the plastic tensioner out the way, it is reversed threaded but then the nut came off easily, also got myself some HEX sockets as the oil pump hex bolts are super tight. Oil pump and all return lines out the way:

The new bearings are coated and clearly packaged as lower and upper, a picture of a new bearing in end cap, you can clearly see the coating:

Now the fun started, first of all the upper bearings are so fiddly, not much room to get your hands up there, so takes a few attempts, luckily both the bearings and crank survived as I made sure to not touch them.

Plus Andy gave me an excellent idea of when end-cap is removed to then crank the engine until the piston is at the top and to then crank other direction bringing crank back down but leaving the piston dangling in the air, this worked very well.

ARP BOLT ISSUE!!

So all was good, I went to put the ARP bolts in and even though I have the larger 11mm ARP bolts (10mm is other size) they do not seem to torque up. They tighten up by hand just fine (only tried one) but when trying to torque up to the 50lb/ft as per instructions the bolt comes lose again.

Trust me when this happened I absolutely pooed myself as I thought I had stripped the threads. But the ARP bolt came out look fine, again it hand tightens but comes lose when trying to torque up. So one of two things is wrong, either the ARP bolts has stripped some of the thread in the rod end or they are too small. The stock bolts which are actually a 12mm bolt head go in and torque up just fine, no issues.

Tomorrow I am going to buy a new smaller range torque wrench as the wrench I was using was a Halfords big unit with a range of 50lb/ft - 150+ lb/ft so maybe it is not working quite so well and was trying to apply a lot more than 50lb/ft. Though the stock bolts were in extremely tight, took plenty of leverage to undo them.

So will give the ARP's one last try tomorrow with a smaller torque wrench but if that fails then I guess I will just stick with the BMW OEM bolts, BMW TIS says to re-use the bolts but I think I shall order new ones as you simply do not know if they are stretched or not?

A picture comparing the stock M12 bolt (left) to the ARP M11 bolt (right).

So you can see ARP use less threads and BMW use more, so it could have maybe stripped some threads in the ROD end but as the BMW uses more threads and has a lower tightening torque the stock bolt torques up fine.

Question is as I cannot really tell do you guys reckon the ARP bolts shaft/thread is actually 1mm less in diameter compared to stock or they both the same and only the head is different in size?

OLD Bearings VS NEW!

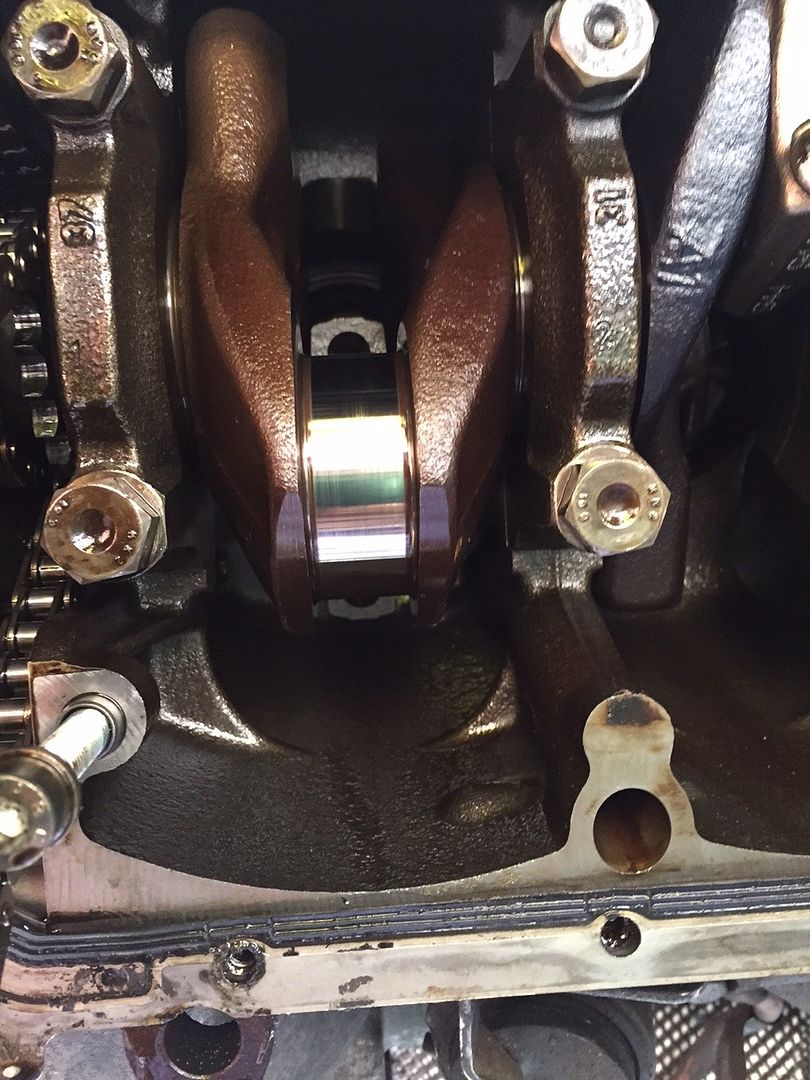

Anyway all the bearings were coming out and were all looking fine, I was beginning to worry that maybe I had another issue. But the last cylinder I did was number ONE.

As soon as I took the end cap of I noticed an issue, which was the end cap was quite a bit hard to get off and when it did come off the shell remained on the crank as did the rod side as well.

At this stage I though none of the others did this and feared they were maybe welded to the crank but I touched them and they did move they just seem hydrolocked to the crank with oil, yes oil another good sign.

I got them off and well they tell a story:

This was close, very close!!!!

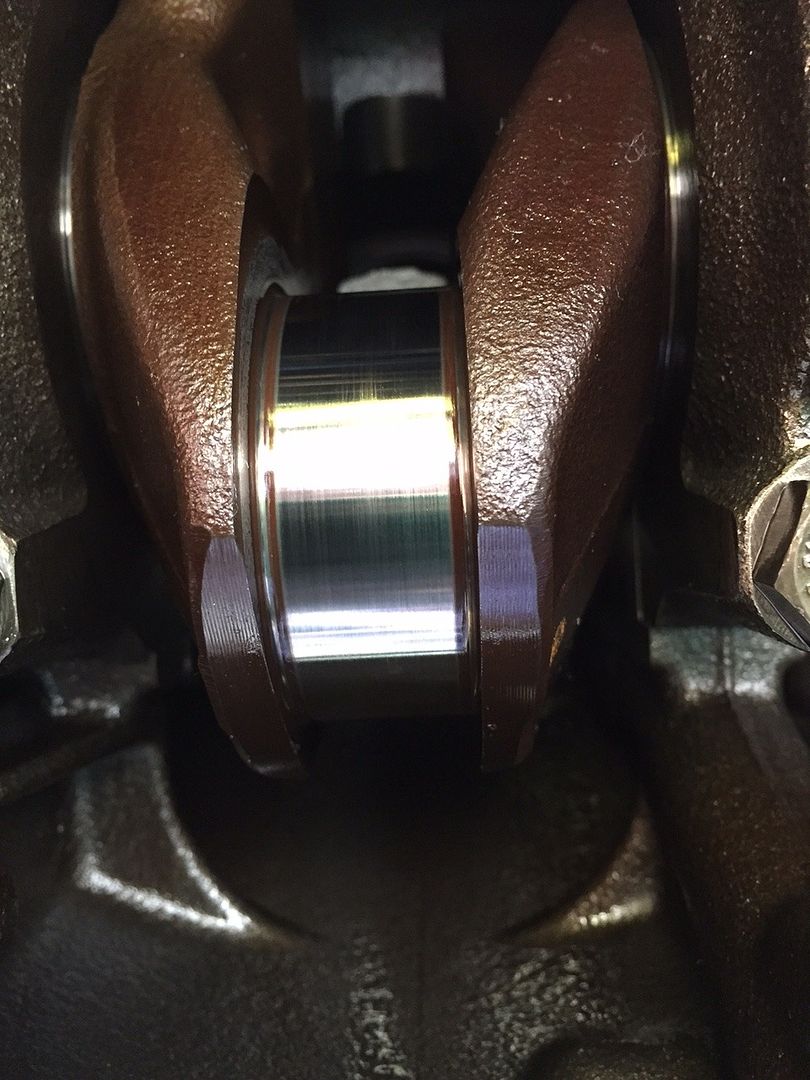

I inspected the crank and much to my relief it looked identical to how the crank looked at all the other cylinders, nice and shiny with no marks, scratches, pitting:

That's a relief!!

So for now I've put it all back together, I am gonna buy a smaller range torque wrench from Halfords tomorrow and give the ARP's another shot, if they still just spin or if anyone here is 100% sure the ARP bolts do look smaller then I shall just stick the BMW bolts, but shall re-order some fresh ones from BMW as I have no idea if any of the stock bolts are stretched or not so don't particular want to chance re-using them, just to have a repeat of this issue down the road.

Based on getting new bolts it is just one more days work to get them tightened, sump back on and rest of the car put all back together.