- Joined

- 7 Dec 2010

- Posts

- 223

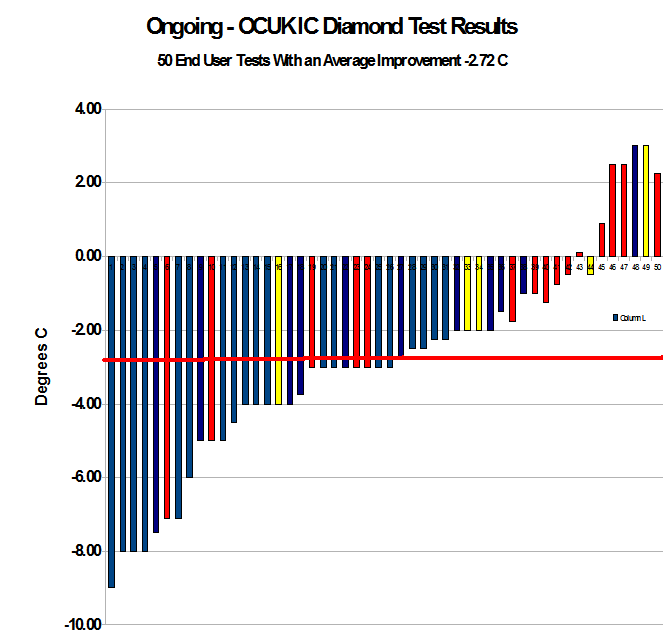

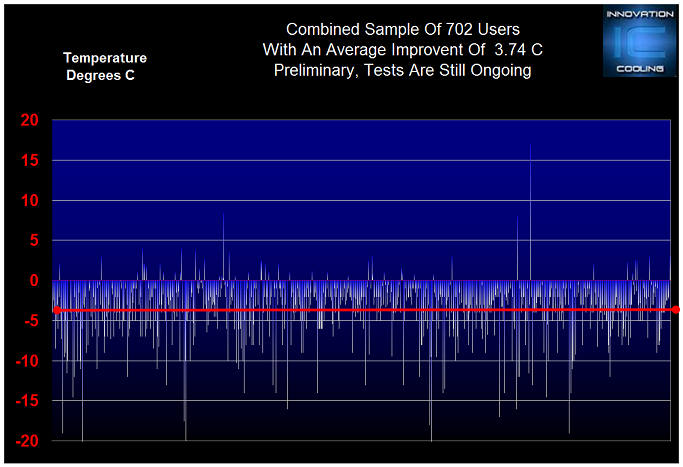

Actually pretty much the way we do our comparisons, multiple test dies for months and comparisons made on the same die. We record the data every morning to get a trend line up or down. have to be rigorous about ambient's

You and WingZero30 should be in R&D as your interest lies in that direction.

You and WingZero30 should be in R&D as your interest lies in that direction.