You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

***Official Electronics Thread of Officialness (it starts off with lots of Nixie Tube Clock goodness

- Thread starter Aod

- Start date

More options

Thread starter's postsWouldn't mind a build log for this sort of thing, including plans etc. Ive always fancied making my own PCB's, but do not know where to start!

I'm making a PCB right now! It's currently in the developer tank, which is why I'm able to post here.

I remembered your request so I'm taking photos on my phone and I'll try and write it up later on. Although I'm using the etching facilities at work, it's no more advanced than a glorified hobbyist setup so it's still the same procedure.

The ability to make your own PCBs is so useful. I'd highly recommend learning.

I always intended to but never got around to it. As for etching, I have a laser cutter, so cutting out stencils etc for photoresist is not an issue. I also have a laser printer, so transparencies are easy as well  . I also now have the space. I also plan on making my own anodising setup.

. I also now have the space. I also plan on making my own anodising setup.

. I also now have the space. I also plan on making my own anodising setup.

. I also now have the space. I also plan on making my own anodising setup.Soldato

- Joined

- 28 Mar 2005

- Posts

- 11,255

- Location

- Newbury

My kit arrived yesterday, so I thought I'd make start today.

I went for the IN-12/IN-17 kit from PVE as I've not done any electronics since my GCSEs, and thought it would be a better re-introduction than one of the big kits, I doubt there's (will definitely be doing a bigger one afterwards though ).

).

Finished the High + Low Voltage components so far. Will probably have another crack later.

Noticed them when I went to get my instructions, they look pretty epic.

I went for the IN-12/IN-17 kit from PVE as I've not done any electronics since my GCSEs, and thought it would be a better re-introduction than one of the big kits, I doubt there's (will definitely be doing a bigger one afterwards though

).

).Finished the High + Low Voltage components so far. Will probably have another crack later.

Pete from PVE emailed me last night to say that he's finished the kits for the IN-18 nixie tube clocks so I ordered one straight away - It looks a beast!

Noticed them when I went to get my instructions, they look pretty epic.

Soldato

- Joined

- 28 Mar 2005

- Posts

- 11,255

- Location

- Newbury

And finished today.

Really enjoyed making it, looking at some other kits already.

Really enjoyed making it, looking at some other kits already.

Pete from PVE emailed me last night to say that he's finished the kits for the IN-18 nixie tube clocks so I ordered one straight away - It looks a beast!

What makes it a beast?

Sounds good. I've been thinking about improving the virtual ground circuit on my CMOY from it's current 741 Op-amp to something else. Was a little put off building that Sijosae's circuit because Tangent says it's the least accurate. Surely it can't be less accurate than a resistor voltage divider ground?

Please update with pics and stuff.

It'll be the least accurate of the buffered circuits, rather than the simple unbuffered ones I would suggest

Circuit messily thrown together on protoboard:

... and a test one

+ and - Inputs on left, and three outputs on right V+ VGND and V-

I will be adding a pair of 0.47uF caps across the outputs in the final circuit. They're not on the original circuit diagram though.

Finally tried my new soldering iron in earnest  . Its so much better than my previous iron, which was a £50 soldering station from the lovely overpriced high street store!

. Its so much better than my previous iron, which was a £50 soldering station from the lovely overpriced high street store!

Bought this one:

http://www.ersa.com/art-0rds80-358-1997.html

I say I bought it, but really, it was a present from my business to me. Wanted one with micro tips, and plenty of different designs. Got some nift features, like standby power, auto off and programmable temperature buttons. A worthwhile investment for me!

. Its so much better than my previous iron, which was a £50 soldering station from the lovely overpriced high street store!

. Its so much better than my previous iron, which was a £50 soldering station from the lovely overpriced high street store!Bought this one:

http://www.ersa.com/art-0rds80-358-1997.html

I say I bought it, but really, it was a present from my business to me. Wanted one with micro tips, and plenty of different designs. Got some nift features, like standby power, auto off and programmable temperature buttons. A worthwhile investment for me!

I use a £60 Precision Gold 48W soldering station from a well known high street store, it was on offer for £30 back in Jan 2008, done me fine so far.

This is my home made stepper motor driver for my MakerBot extruder, it uses a Pololu A4983 as the driver chip. It's been working fine for a few months now, I really need to get the schematic drawn up as several people have asked me for it.

This is my home made stepper motor driver for my MakerBot extruder, it uses a Pololu A4983 as the driver chip. It's been working fine for a few months now, I really need to get the schematic drawn up as several people have asked me for it.

Mine was a 48W LCD Display Solder Station. Don't get me wrong, at 5 years of faithful service, it done well! But the major limitation was tips. When doing SMD work, it struggled. There were never really any decent replacement tips, and the large tips could have been better. They were a PITA to change, and never fit once used a few tips due to the thermal expansion. This new one is a joy to use, mainly because its clearly a production iron, but then, I never paid for it  .

.

I plan on buying the latest extruder for my makerbot, the one I have is #28, and 2nd gen. Its been mothballed for the past 2 years since I just have not had time to do the work it needs! Needs new Z rods, as the ones I have are not straight, the HBP needs installing, and the extruder could do with an upgrade as it was never that reliable!

.

.I plan on buying the latest extruder for my makerbot, the one I have is #28, and 2nd gen. Its been mothballed for the past 2 years since I just have not had time to do the work it needs! Needs new Z rods, as the ones I have are not straight, the HBP needs installing, and the extruder could do with an upgrade as it was never that reliable!

TBH... When I first saw the clock, I thought it was fugly but as I read on I think I've been bitten by the bug. Especially as it can be set with GPS (thanks freek). I may challege my boss to see who can make the best one with housing; as we get 4 weeks off for Christmas. But I have a feeling that he may chicken out like he did yesterday when he asked me to soldier a caps back on to a laptop system board and to replace a circuit board from a tolley that he took apart.

Last edited:

Also picked up a old scanner to make a uv exposure box in a little bit.

Now to try and set fire to something not attached to me

Have you made any progress?

Soldato

- Joined

- 27 Apr 2004

- Posts

- 5,549

- Location

- Doncaster, S.Yorks

Got to stop reading this thread, im almost about to cave in and purchase a kit but not quite sure which one, i like the ones with stand up tubes, but OTF's one is quite nice looking aswell and more so from price point of view.

OK, here's my guide to making a PCB.

First of all, you need to design the layout for your circuit board. I use Autocad because it's very easy to make the layouts in, but it doesn't really matter what you use as long as you can print it out. What you're after is a negative image i.e. black where you don't want any copper. It's not that easy to do in Autocad so I print out a normal image on a transparency like so...

...and then reverse it using a UV sensitive artwork reversal film.

If you've got a printer that has a setting for printing out a negative then you can use that and you don't have to bother with the reversal. Alternatively, plan ahead and draw a negative to begin with. Now I use a laminator and laminate the board with photoresist myself, but you can buy pre-laminated boards which is probably a better bet for a hobbyist. I then take the laminated board, place the negative image on top of it and then expose it in a UV lightbox for about 14-15 seconds. Once this is done, you get something that looks like this...

The image is bad because it was taken in a low light environment as I was trying to avoid unintentional exposure (ooh err missus). The dark blue is where the photoresist has been exposed to UV light. These are the bits we want to remain copper. The grey-blue areas are unexposed photoresist. At this stage, I peel off the protective sheet and place the board in the developer tank. Developer is potassium carbonate and it should be diluted to about 25:1. I think you can get this from RS. After 15 minutes in the tank, it looks like this...

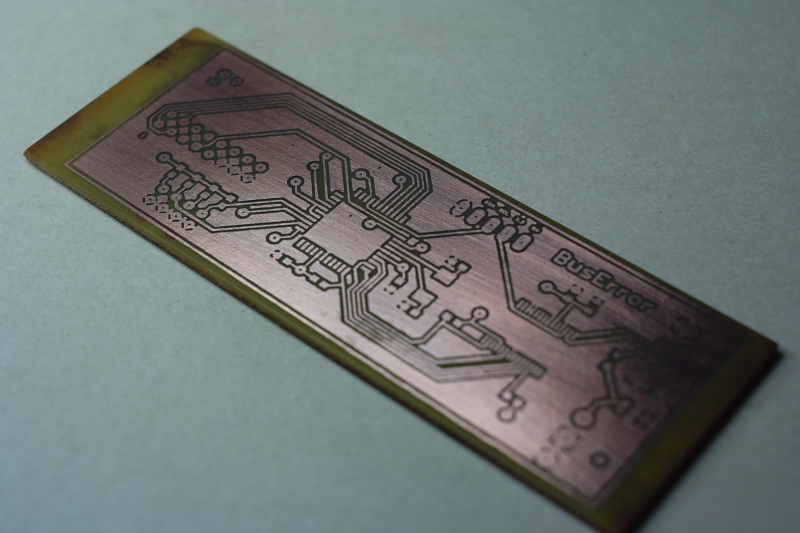

Now you can easily see that the unexposed photoresist has been removed. When the board goes in the etching tank, the exposed copper will be removed, leaving only the copper underneath the remaining photoresist. The etching chemical is ferric chloride and it's nasty stuff so be careful with it. I also can't remember what concentration is used, so consult the data sheet carefully!

After ten minutes in the etching tank, the copper is all gone bar a little around the edges, which is why you always leave a little bit of space around your intended PCB. There's only one problem - our lovely PCB is still covered by photoresist. The solution is very easy to get hold of - surgical spirit. You don't need much. I fill a spray bottle with it and just spray a little over the surface. It takes a few minutes for the reaction to start, but when it does, this happens...

You then put the board in some water and the photoresist comes away with no effort to leave you with a lovely PCB.

All you need to do then is cut to size and drill the holes. It will probably take a couple of hours to complete this process on your first go, but you'll get much quicker with practice. Note that where I say "tank" you can easily substitute any old container which is big enough to hold your board and which won't leak the chemicals. Always read the chemical data sheets and wear rubber gloves when handling boards which have been in chemicals.

I hope you enjoyed this little PCB build log and hope it inspires some of you to investigate making some boards.

First of all, you need to design the layout for your circuit board. I use Autocad because it's very easy to make the layouts in, but it doesn't really matter what you use as long as you can print it out. What you're after is a negative image i.e. black where you don't want any copper. It's not that easy to do in Autocad so I print out a normal image on a transparency like so...

...and then reverse it using a UV sensitive artwork reversal film.

If you've got a printer that has a setting for printing out a negative then you can use that and you don't have to bother with the reversal. Alternatively, plan ahead and draw a negative to begin with. Now I use a laminator and laminate the board with photoresist myself, but you can buy pre-laminated boards which is probably a better bet for a hobbyist. I then take the laminated board, place the negative image on top of it and then expose it in a UV lightbox for about 14-15 seconds. Once this is done, you get something that looks like this...

The image is bad because it was taken in a low light environment as I was trying to avoid unintentional exposure (ooh err missus). The dark blue is where the photoresist has been exposed to UV light. These are the bits we want to remain copper. The grey-blue areas are unexposed photoresist. At this stage, I peel off the protective sheet and place the board in the developer tank. Developer is potassium carbonate and it should be diluted to about 25:1. I think you can get this from RS. After 15 minutes in the tank, it looks like this...

Now you can easily see that the unexposed photoresist has been removed. When the board goes in the etching tank, the exposed copper will be removed, leaving only the copper underneath the remaining photoresist. The etching chemical is ferric chloride and it's nasty stuff so be careful with it. I also can't remember what concentration is used, so consult the data sheet carefully!

After ten minutes in the etching tank, the copper is all gone bar a little around the edges, which is why you always leave a little bit of space around your intended PCB. There's only one problem - our lovely PCB is still covered by photoresist. The solution is very easy to get hold of - surgical spirit. You don't need much. I fill a spray bottle with it and just spray a little over the surface. It takes a few minutes for the reaction to start, but when it does, this happens...

You then put the board in some water and the photoresist comes away with no effort to leave you with a lovely PCB.

All you need to do then is cut to size and drill the holes. It will probably take a couple of hours to complete this process on your first go, but you'll get much quicker with practice. Note that where I say "tank" you can easily substitute any old container which is big enough to hold your board and which won't leak the chemicals. Always read the chemical data sheets and wear rubber gloves when handling boards which have been in chemicals.

I hope you enjoyed this little PCB build log and hope it inspires some of you to investigate making some boards.

You can do pretty much the same thing by printing on magazine paper in a laser printer, using a cloth iron to bind it to a normal copper clad board, dunk the board in water to remove the paper (that leaves the toner stuck to the board) and etching as usual.

I can easily get traces if 12 mils (12/1000th inch). Minimum I do is 8, which is way more than necessary in most cases..

I can easily get traces if 12 mils (12/1000th inch). Minimum I do is 8, which is way more than necessary in most cases..