matt100 said:oh I get you, you mean like a prop? I could try that but it's not sagging, its bending under pressure I think as per the diagram above..

I'll play tonight and see what I can do..

As an aside, do we think I could get this thing into the bios with no water etc? Just using the waterblock as a big passive heatsink for literally 30 seconds just to make sure it boots before I make the working space even more difficult?

Yeah that should be fine. Your copper waterblock weighs 330g, so its heat capacity is ~120J/K. Assuming your proc disappates 80W, running for 30 seconds would heat it up by no more than 30s*(80W)/(120J/K) = 20°C. That's ignoring heat loss to surroundings too (blow into one pipe of the waterblock if you want to get some airflow going, hehe).

The pentium won't cook itself, it can throttle if things get too hot anyways.

Last edited:

and I really don't want to be dreaming up solutions at 1am!

and I really don't want to be dreaming up solutions at 1am! ics..

ics..

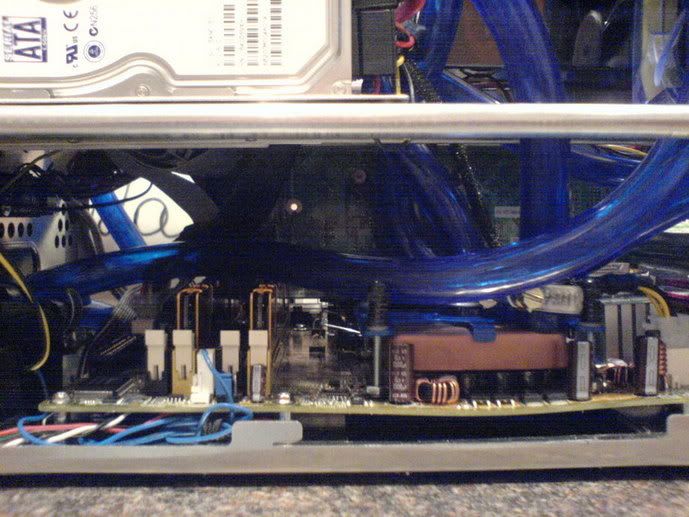

that dremel is earning its keep here.. also need to cut away a bit more of the backplate because the hoseclip is in the way...

that dremel is earning its keep here.. also need to cut away a bit more of the backplate because the hoseclip is in the way...