You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Random 3D printing chatter

- Thread starter Cenedd

- Start date

More options

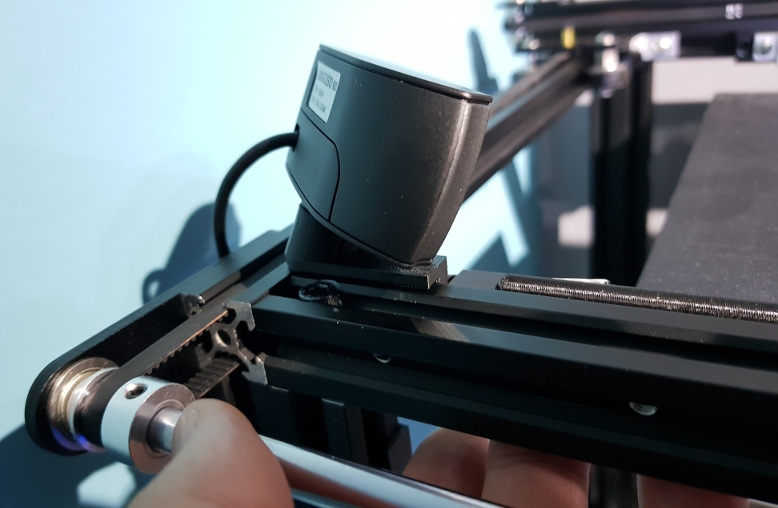

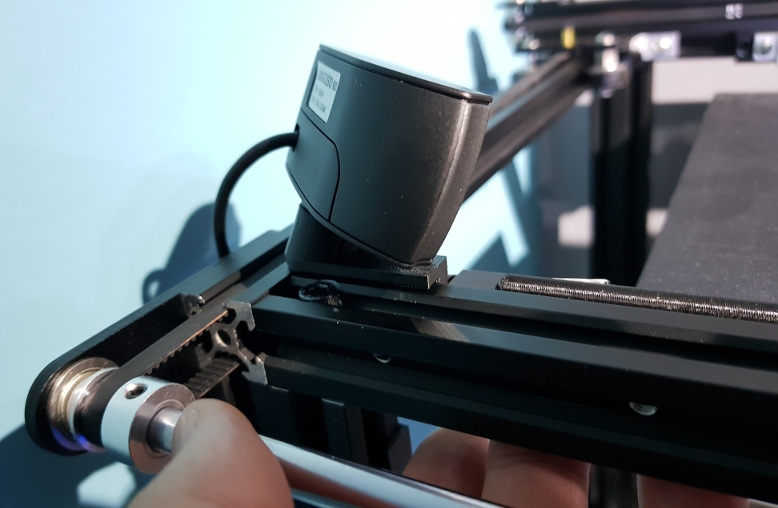

Thread starter's postsGot the camera mount done. In the end I opted to keep it simple and do a fixed mount. Got rid of the male thread (which worked well) and replaced with a female M4 thread purely to make it easier to print - awkward protrusion on only one side then. Didn't immediately fit a bolt but ran a tap through it carefully and it cleaned up fine. The piece of duct tape you can see is a 'magic' "repair" for the first set of LEDs flickering on the light strip....already.

Lol yes, big spool!

My dog took the model boat off my desk. It didn't end well for the boat...

Chris, do you know if that natural Byotec filament will take a stain/dye after its been printed?.

Associate

- Joined

- 23 Jun 2004

- Posts

- 2,470

- Location

- Macclesfield

Chris, do you know if that natural Byotec filament will take a stain/dye after its been printed?.

No I don't, but if I had to guess I'd say no. The wood filaments only take stain because of the actual powdered wood being in there.

No I don't, but if I had to guess I'd say no. The wood filaments only take stain because of the actual powdered wood being in there.

OK Chris, cheers for the info.

Made my first mistake.

I took the sdcard out while it was printing. It came to a stop

Yup, that'll definitely stop it

Yup, that'll definitely stop it

Never had that before

Be glad when they get the Eprom working.

Going to buy some air tight Cereal containers for the filament.

Never had that before

Be glad when they get the Eprom working.

Going to buy some air tight Cereal containers for the filament.

I use Octoprint so no worries with SD cards now.

I need to get some more bags. Not got enough to cover all my filament and a couple of them have gone bad from moisture.

I use Octoprint so no worries with SD cards now.

I need to get some more bags. Not got enough to cover all my filament and a couple of them have gone bad from moisture.

Dry them out in an oven about 40c for a few hours.

Or get a food drier for £30 to do the job.

I am hoping I can get the CR-6 SE to work wireless at some point.

But for the money it's great.

Dry them out in an oven about 40c for a few hours.

Or get a food drier for £30 to do the job.

I am hoping I can get the CR-6 SE to work wireless at some point.

But for the money it's great.

I don't have a thermometer to test how low my oven will go. Far too many posts on reddit of melted spools

I do plan to get a cheap dehydrator though for sure.

Any of you guys had issues with extruder jamming and can shed any light on mine? I'm trying to print a part that has some complicated support - it's essentially a lid and there are cut-outs in the top of it so it's running support from the bed to where it starts the roof. Don't ideally want to print it the other way up as there would be marring on the show-face then. Problem I'm getting is that it gets 1.5 to 2.5mm up the print and then you can hear the extruder clicking as it fails to feed. I've pulled it back out, cleaned the nozzled just in case and re-threaded it. Feeds smooth. What seems to happen is that the teeth of the extruder chew up the filament enough that it flattens it - this happens a few times and then it's too difficult to push it down the tube and it fails. Had it print a number of layers with no filament. I've been running a 6mm retract as guides said to start at 5mm and go up from there to cure dribbling. This worked pretty well for a 23.5 hour print the other day but I'm guessing that with the small, intricate supports being printed, that there are lots of repeated retracts and that's chewing it too much. It could be though that it's getting chewed when it fails to feed - I'm not really certain if it's cause or effect. I'm trying a print now (same model) but with the retract set to 1mm to see if that helps. Mainly after anyone's experience of this to know if I'm barking up the right tree. Printer, for reference, is an Ender 5 Pro running a Capricorn bowden tube.

Managed some Evryone TPU prints earlier. Pretty much same settings as PLA - including the 6mm retract. Tried it without and it was too dribbly. I think the speed settings in Fusion 360 (as a slicer) are pretty slow anyway as the recommend 'slow' speeds were significantly faster than the defaults - which are 26mm/s for internal perimeters, 18mm/s for external perimeters, 0.4 multiplier for first layer, 250mm/s for rapid travel (not extruding) and I've no idea for infil - can't find anything else with a mm/s unit!

Edit: ....and now, I find it! 60mm/s sparse infill, 40mm/s solid infill.

Managed some Evryone TPU prints earlier. Pretty much same settings as PLA - including the 6mm retract. Tried it without and it was too dribbly. I think the speed settings in Fusion 360 (as a slicer) are pretty slow anyway as the recommend 'slow' speeds were significantly faster than the defaults - which are 26mm/s for internal perimeters, 18mm/s for external perimeters, 0.4 multiplier for first layer, 250mm/s for rapid travel (not extruding) and I've no idea for infil - can't find anything else with a mm/s unit!

Edit: ....and now, I find it! 60mm/s sparse infill, 40mm/s solid infill.

Any of you guys had issues with extruder jamming and can shed any light on mine? I'm trying to print a part that has some complicated support - it's essentially a lid and there are cut-outs in the top of it so it's running support from the bed to where it starts the roof. Don't ideally want to print it the other way up as there would be marring on the show-face then. Problem I'm getting is that it gets 1.5 to 2.5mm up the print and then you can hear the extruder clicking as it fails to feed. I've pulled it back out, cleaned the nozzled just in case and re-threaded it. Feeds smooth. What seems to happen is that the teeth of the extruder chew up the filament enough that it flattens it - this happens a few times and then it's too difficult to push it down the tube and it fails. Had it print a number of layers with no filament. I've been running a 6mm retract as guides said to start at 5mm and go up from there to cure dribbling. This worked pretty well for a 23.5 hour print the other day but I'm guessing that with the small, intricate supports being printed, that there are lots of repeated retracts and that's chewing it too much. It could be though that it's getting chewed when it fails to feed - I'm not really certain if it's cause or effect. I'm trying a print now (same model) but with the retract set to 1mm to see if that helps. Mainly after anyone's experience of this to know if I'm barking up the right tree. Printer, for reference, is an Ender 5 Pro running a Capricorn bowden tube.

Managed some Evryone TPU prints earlier. Pretty much same settings as PLA - including the 6mm retract. Tried it without and it was too dribbly. I think the speed settings in Fusion 360 (as a slicer) are pretty slow anyway as the recommend 'slow' speeds were significantly faster than the defaults - which are 26mm/s for internal perimeters, 18mm/s for external perimeters, 0.4 multiplier for first layer, 250mm/s for rapid travel (not extruding) and I've no idea for infil - can't find anything else with a mm/s unit!

Edit: ....and now, I find it! 60mm/s sparse infill, 40mm/s solid infill.

Retractions, I had this on a print a while back and I just slowed down the retractions. I used to retract at 100mm/s now its down at like 60mm/s, I retract 7mm as I found a longer retraction actually helped rather than a shorter one.

Associate

- Joined

- 23 Jun 2004

- Posts

- 2,470

- Location

- Macclesfield

Any of you guys had issues with extruder jamming and can shed any light on mine? I'm trying to print a part that has some complicated support - it's essentially a lid and there are cut-outs in the top of it so it's running support from the bed to where it starts the roof. Don't ideally want to print it the other way up as there would be marring on the show-face then. Problem I'm getting is that it gets 1.5 to 2.5mm up the print and then you can hear the extruder clicking as it fails to feed. I've pulled it back out, cleaned the nozzled just in case and re-threaded it. Feeds smooth. What seems to happen is that the teeth of the extruder chew up the filament enough that it flattens it - this happens a few times and then it's too difficult to push it down the tube and it fails. Had it print a number of layers with no filament. I've been running a 6mm retract as guides said to start at 5mm and go up from there to cure dribbling. This worked pretty well for a 23.5 hour print the other day but I'm guessing that with the small, intricate supports being printed, that there are lots of repeated retracts and that's chewing it too much. It could be though that it's getting chewed when it fails to feed - I'm not really certain if it's cause or effect. I'm trying a print now (same model) but with the retract set to 1mm to see if that helps. Mainly after anyone's experience of this to know if I'm barking up the right tree. Printer, for reference, is an Ender 5 Pro running a Capricorn bowden tube.

Managed some Evryone TPU prints earlier. Pretty much same settings as PLA - including the 6mm retract. Tried it without and it was too dribbly. I think the speed settings in Fusion 360 (as a slicer) are pretty slow anyway as the recommend 'slow' speeds were significantly faster than the defaults - which are 26mm/s for internal perimeters, 18mm/s for external perimeters, 0.4 multiplier for first layer, 250mm/s for rapid travel (not extruding) and I've no idea for infil - can't find anything else with a mm/s unit!

Edit: ....and now, I find it! 60mm/s sparse infill, 40mm/s solid infill.

Many printer problems can be put down to using poor quality filament, some (usually cheaper ones but not always!) are simply more prone to blocking the nozzle. Also, some nozzles are not made that well and inside the bore just before the aperture there is a sharp(er) shoulder rather than a smooth transitional cone shape. That increases resistance. Then there are things like using a temperature that is too low for the filament (even PLA can vary 190-230, and the thermistors can lie about what the actual temperature is). There's obviously too much resistance for the extruder, and whilst you could try increasing the pressure on the knurled drive gear with the adjustment screw I don't feel that is the way forward here - not unless it was a consistent finding with a selection of filaments. Honestly, I would try some known-good filament first and see if the problem persists.

It doesn't seem to be the nozzle that's presenting the resistance to be honest. It seems to be the filament in the tube when there are multiple locations of chewing on in - one is ok but a few and it becomes a problem. I've probably printed half a roll of this stuff so far - it's dribbly and shatters if you look at it wrong but hasn't previously given me this sort of problem until Fusion sliced some overly stupid support at it. I'm printing it at the moment with 1mm retraction and it so far it's got about 4mm up which is a significant improvement. Doesn't seem to be too dribbly either for some reason. Have noticed it hitting the support it's just roughed as it travels (often seemingly pointlessly) to another area to print some other support and then back again. The joy and bane of Fusion here is that it is constantly updated.....sometimes for the better and sometimes not so much. One I particularly noticed was that they briefly got rid of the move bed down (or up, if you prefer) after the end of the print. It still had a park command but no Z move so the nozzle sat where it finished and melted a little puddle in the print. That's back again now - which saves editing it in manually.

Ok, Fusion defaults to 30mm/s for retracts. Good to know I'm not well outside the retraction range for this setup. Not sure why it's not dribbling more with only 1mm when it did at 5mm and 0.5mm. The joys of the 3D printer eh?!Retractions, I had this on a print a while back and I just slowed down the retractions. I used to retract at 100mm/s now its down at like 60mm/s, I retract 7mm as I found a longer retraction actually helped rather than a shorter one.

Associate

- Joined

- 23 Jun 2004

- Posts

- 2,470

- Location

- Macclesfield

Well I've never had the extruder chew a chunk out of the filament except when there was a blocked nozzle (or exceptionally high resistance for some other reason - like the teflon tube in the hot end was burned and swollen). I've had nozzles that block again 5 mins after clearing (or thought I'd cleared it...) because there was something I was just pushing back up into the body of the thing. Once I got so fed up with one nozzle I heated it to cherry red with a torch to burn it out, then cleaned with 1.9 and 0.4mm drills  It actually still worked after that - no blockages either.

It actually still worked after that - no blockages either.

It actually still worked after that - no blockages either.

It actually still worked after that - no blockages either.Ok, Fusion defaults to 30mm/s for retracts. Good to know I'm not well outside the retraction range for this setup. Not sure why it's not dribbling more with only 1mm when it did at 5mm and 0.5mm. The joys of the 3D printer eh?!

That could be your prime amount, there is a setting for how much "extra" filament is used after a retraction to be honest I just played around with a ton of retraction settings in the slicer until the printer was happy and the results looked decent. if you do shorter retracts with the same prime the net result is more filament at the end of the nozzel. I only know this because i'm using a random extruder that has no instructions

I've set up the new printer pretty much now so ill be playing with that properly in the coming weeks so something new to learn.

I've set up the new printer pretty much now so ill be playing with that properly in the coming weeks so something new to learn.

Last edited:

Cheers, that's helpful. Makes sense to have a setting for "unretract distance". I have multiple references to "prime" in Fusion....but none of them, of course, look related to what you've said.

There's "nozzle priming" but that's a line before printing to get it flowing.

There's "Change Extra Restart Length" but I think that's if you have multiple extruders since it describes as "Extra restart extrusion after tool change".

Some stuff on "Prime Extrusion Width" and "Prime Edge Clearance Distance" but it's on the "Skirt-brim" tab.

My dimensions don't seem to be coming out exactly as they should so I'm not sure things are going to fit quite right anyway. eg length modelled at 118.1mm and printed at 117.6mm. Width modelled at 56.5mm, printed at 56.1mm. These are near enough the same error margin over a long enough distance that I don't think it's a percentage size difference....although, they are in different axes so I suppose it could be different percentages per axis. Definitely a problemfor tomorrow to be replaced with a beer!

There's "nozzle priming" but that's a line before printing to get it flowing.

There's "Change Extra Restart Length" but I think that's if you have multiple extruders since it describes as "Extra restart extrusion after tool change".

Some stuff on "Prime Extrusion Width" and "Prime Edge Clearance Distance" but it's on the "Skirt-brim" tab.

My dimensions don't seem to be coming out exactly as they should so I'm not sure things are going to fit quite right anyway. eg length modelled at 118.1mm and printed at 117.6mm. Width modelled at 56.5mm, printed at 56.1mm. These are near enough the same error margin over a long enough distance that I don't think it's a percentage size difference....although, they are in different axes so I suppose it could be different percentages per axis. Definitely a problem

Yup. Prime then paint.Hey.

Is Acrylic paint ok for PLA?

Vallejo acrylics work nicely