You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Random 3D printing chatter

- Thread starter Cenedd

- Start date

More options

Thread starter's postsI love the screen setup

It's really coming together....

Finger on the power switch when you do the first Z home lol! I've seem people crah the nozzle big style!

I used to trip the BLTouch with my finger.

Associate

- Joined

- 23 Jun 2004

- Posts

- 2,470

- Location

- Macclesfield

Do those textured glass plates only stick PLA? Tried some PET-G and it just won't stick to the bed - and 1st layer is well squished onto it. Tried scrubbing it with IPA and it was slightly better but not good enough to prevent prints coming off mid-print. Do I have to resort to a glue stick? (this is on my Sidewinder X1 - not tried the CR-6 yet).

Do those textured glass plates only stick PLA? Tried some PET-G and it just won't stick to the bed - and 1st layer is well squished onto it. Tried scrubbing it with IPA and it was slightly better but not good enough to prevent prints coming off mid-print. Do I have to resort to a glue stick? (this is on my Sidewinder X1 - not tried the CR-6 yet).

Chris, on my CR6 textured side up, PetG I use a glue stick, print at 230 head 60 bed and they come out perfect, wait till bed is cold before you remove the print.(still hard to remove print)

I love the screen setup

It's really coming together....

I used to trip the BLTouch with my finger.

Yea the screen is an awesome little addon. Need to buy an SKR for my old printer now so I can use the full touch screen goodness on that as well. The bl touch I have on there now just fires stuff

On thing I can tell you for nothing, today we need to correct all the splices in the wiring. The skr doesn't like the way the endstops for y & z min share power pins, it also gets stroppy about the way the fans are wired and share pins with an endstop. If you trip that endstop the board turns off (and yes ive checked the wiring and board pinout many times), it is super odd. I see why they did it as it significantly cuts down on wire runs and with the ramps board it was fine but here odd things be happening.

Last edited:

I used to trip the BLTouch with my finger.

That's far too much of a good idea and takes all the risk out of it. Why didn't I think of that?

Associate

- Joined

- 23 Jun 2004

- Posts

- 2,470

- Location

- Macclesfield

Chris, on my CR6 textured side up, PetG I use a glue stick, print at 230 head 60 bed and they come out perfect, wait till bed is cold before you remove the print.(still hard to remove print)

Thanks, will have to order a glue stick

Associate

- Joined

- 23 Jun 2004

- Posts

- 2,470

- Location

- Macclesfield

Associate

- Joined

- 23 Jun 2004

- Posts

- 2,470

- Location

- Macclesfield

Can we see some results?

lol sure when I have some, just unpacked it a few minutes ago

lol sure when I have some, just unpacked it a few minutes ago

Hah, crack on then!

Do those textured glass plates only stick PLA? Tried some PET-G and it just won't stick to the bed - and 1st layer is well squished onto it. Tried scrubbing it with IPA and it was slightly better but not good enough to prevent prints coming off mid-print. Do I have to resort to a glue stick? (this is on my Sidewinder X1 - not tried the CR-6 yet).

I heat up the bed to 60c then do a auto bed level.

Then press home and make sure some print paper can go in between the bed and nozzle.

If not or it's to lose. Use the up\down key next to the home button to get it righ.

Associate

- Joined

- 23 Jun 2004

- Posts

- 2,470

- Location

- Macclesfield

Hah, crack on then!

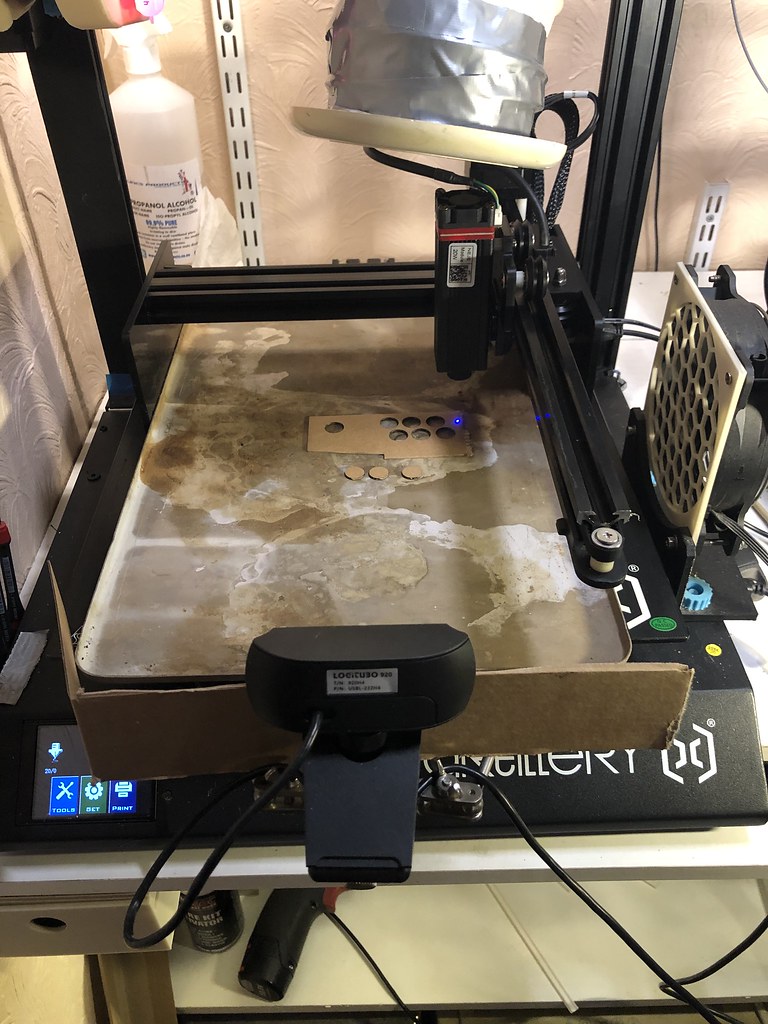

Laser hardware and drivers/supplied software were easy. Getting it to behave with LightBurn was a right PITA. Finally sorted at 3am today after trawling wiki and LightBurn forum. Using an old oven tray to protect the printer bed so I can cut right through stuff. Only sliced some cardboard up so far. Could not do this without the extractor and that's for sure - takes a minute to clear the smell of burning even then. I have a smoke alarm right above it (a bit of extra protection in case an overnight 3D print goes wrong) but it hasn't been triggered yet

,

,I heat up the bed to 60c then do a auto bed level.

Then press home and make sure some print paper can go in between the bed and nozzle.

If not or it's to lose. Use the up\down key next to the home button to get it righ.

Got everything on the printer including auto bed levelling (currently using bilinear) and also lcd levelling but havent played with that yet, baby stepping is all set up, upped the stepping to 1/32 stepping on the 2208 drivers and also fiddled with the abl margins for about an hour to really get it spot on. I have trammed the hell out of it and tested it like crazy, I think it's pretty much ready for the prime time. Literally all I need to do is set up all the fans, dial in the extruder properly and print a benchy

Oh and its basically silent in operation so good work on the build my friend

Oh and its basically silent in operation so good work on the build my friend

Oh and print some brackets/cases for all the new hardware. I did have to rip out all the wiring for y/z min yesterday as I was getting some odd behaviours on endstops with this board. The z endstop is no longer necessary so removed that entirely as the bl touch acts as z endstop for homing. So bit by bit it's evolving to a ready point. I'm just really taking my time with it, you can't rush perfection.

Last edited:

Got everything on the printer including auto bed levelling (currently using bilinear) and also lcd levelling but havent played with that yet, baby stepping is all set up, upped the stepping to 1/32 stepping on the 2208 drivers and also fiddled with the abl margins for about an hour to really get it spot on. I have trammed the hell out of it and tested it like crazy, I think it's pretty much ready for the prime time. Literally all I need to do is set up all the fans, dial in the extruder properly and print a benchyOh and its basically silent in operation so good work on the build my friend

Oh and print some brackets/cases for all the new hardware. I did have to rip out all the wiring for y/z min yesterday as I was getting some odd behaviours on endstops with this board. The z endstop is no longer necessary so removed that entirely as the bl touch acts as z endstop for homing. So bit by bit it's evolving to a ready point. I'm just really taking my time with it, you can't rush perfection.

Looking forward to your first print

@ChrisLX200 that cut is very crisp, awesome result!

Looking forward to your first print

Here it is a 20x20 config cube! An almost perfect cube off by just .1 of a mm in every axis.

Some things I have been fighting with:

1) Cura doesn't seem to want to print properly - every time it seems to dig down on the second layer (not raising z enough) killing the print - If I send the same gcode to Pronterface it prints fine. Cura is also doing weird things randomly on certain models like printing half the first layer and then jumping 2 cm across the bed and starting again, very odd and unexplained.

Right now i'm slicing in Prusa Slicer generating gcode, exporting the gcode, modifying in the g29 and then sending that via pronterface - I don't like this so last night I set up Slic3er (sp?) to give it a go toady.

2) All my models print mirrored - So I have to mirror all models before slicing (no idea why this is yet) and it doesn't make sense!

3) The titan - If I use the proper formula for the titan eg (steps per mm = motor steps (200 1.8deg) x micro stepping (changed to 16 using UART to test) x gearing (3) / (hob diameter (7.3) x pie (3.14) - I get 418.8 - However if I then put that into Firmware I get a serious amount of over extrusion so have had to drag this figure back to 260mm steps to get anything like a print. (effectively running about 60/70% extrusion) - It makes zero sense. Unless there is something different about this Titan (?) that isn't covered in the documentation. I know this is a real dea E3D titan as well so am stumped.

I'm half tempted to rip the extruder off and measure the gear wheel and hob wheel to see if they are what they should be. Even weirder I did the 100mm test and with the 418 it pulls the perfect amount through, I genuinely can't explain the extrusion numbers, they make no sense. I guess the gear ratio or hob diameter could be different which will throw out these numbers.

Weirdly it's not only me and seems to be happening for others on core XY - Others in this thread experience the same https://forum.duet3d.com/topic/356/why-am-i-having-to-run-with-an-extrusion-multiplier-of-60

I just cant work out why! And it seems that neither can others.

What ive set up so far:

1) 2208's in UART for that sweet digital adjustment! For troubleshooting i'm currently running 16 stepping.

2) Bilinear bed levelling with custom set margins, using g29 after g28 on every print - Makes a big difference to the first layer and after plenty of testing I can confirm that it is working well for sure. Weirdly there are some bits here that mirror those backwards/mirrored prints. It thinks the front of the machine is the back and the back is the front, so the z probe offsets are backwards as are the bed margins for front/back. Nothing I can change makes it act any differently and if I correct it the problem moves to X rather than Y. (this could be related to the x/y belt setup but I haven't explored that fully). I do know it caught me out and caused almost an entire day of confusion.

3) Baby stepping (not used it yet) - am setting Z offset with eeprom and M851 gcode.

4) Z safe homing and homing with the sensor, all that works pretty damn well.

If anybody here is a bit of a core XY expert then I would love some input

Last edited:

First layer sliced in slic3er.. so far it looks really nice.

Edit - Slicer problems are now fixed, turns out my skipping problems was just the drivers needing more cooling! I now have 2 fans cooling them bad boys. - y mirror problems and extruder confusion remains - I can now slice and print in cura - but I prefer what prusa slicer does first layer!

- y mirror problems and extruder confusion remains - I can now slice and print in cura - but I prefer what prusa slicer does first layer!

Edit - Slicer problems are now fixed, turns out my skipping problems was just the drivers needing more cooling! I now have 2 fans cooling them bad boys.

- y mirror problems and extruder confusion remains - I can now slice and print in cura - but I prefer what prusa slicer does first layer!

- y mirror problems and extruder confusion remains - I can now slice and print in cura - but I prefer what prusa slicer does first layer!

Last edited: