You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

(In Win 901) Asteria II: Rearmoured

- Thread starter LePhuronn

- Start date

More options

Thread starter's postsSoldato

- Joined

- 28 Dec 2017

- Posts

- 9,287

- Location

- Beds

@Smffy may be able to recommend someone to CNC larger sheets as he's got something in his pipeline too.

@Smffy may be able to recommend someone to CNC larger sheets as he's got something in his pipeline too.

What’s the design - if it’s sheet metal I can help point you at somewhere to get it lasered pretty cheap. It depends if it needs milling to add relief to the sheet or just precision cut and bent? If you want large items CNC milled it will be expensive vs laser and bent probably about £40 inc delivery for 3mm Aluminum.

Everything's still in planning stage right now, but the main body would be roughly 670x235mm and a back plate around 300x235mm with a 5x10 hole pattern, both in 3mm. Thing is though there's edge chamfering, a few blind holes and some shallow channels cut into it, hence the milling. And then there's the pair of 15mm radius bends

And that's just the 1st of the set, I have 2 more scratch builds in my crazy brain that would follow similar specs

And that's just the 1st of the set, I have 2 more scratch builds in my crazy brain that would follow similar specs

@Smffy sent you a trust about lasering and bending some aluminium...

Yep! Drop you a replay later when at a desk!

My very first ATX crimp

These are proper 18AWG Molex pins on thin-wall 17AWG wire but crimped using a cheap tool I bought purely for Dupont connectors. Annoyingly it looks like the crimp is perfect, but the tool makes a bit of a mess of my SATA pins and I was looking at doing a few double wire crimps with 16AWG pins which my tool won't do, so gotta buy one anyway

But still, my very first ATX crimp

These are proper 18AWG Molex pins on thin-wall 17AWG wire but crimped using a cheap tool I bought purely for Dupont connectors. Annoyingly it looks like the crimp is perfect, but the tool makes a bit of a mess of my SATA pins and I was looking at doing a few double wire crimps with 16AWG pins which my tool won't do, so gotta buy one anyway

But still, my very first ATX crimp

Last edited:

What's going to annoy me the most is Paracord is slippy and needs something to hook onto. It'll be fine for the standard cables where I can use the pins, but I have a few push-fit SATA power and solder-only connections. Gonna try a heatshrink base or a dab of superglue methinks.

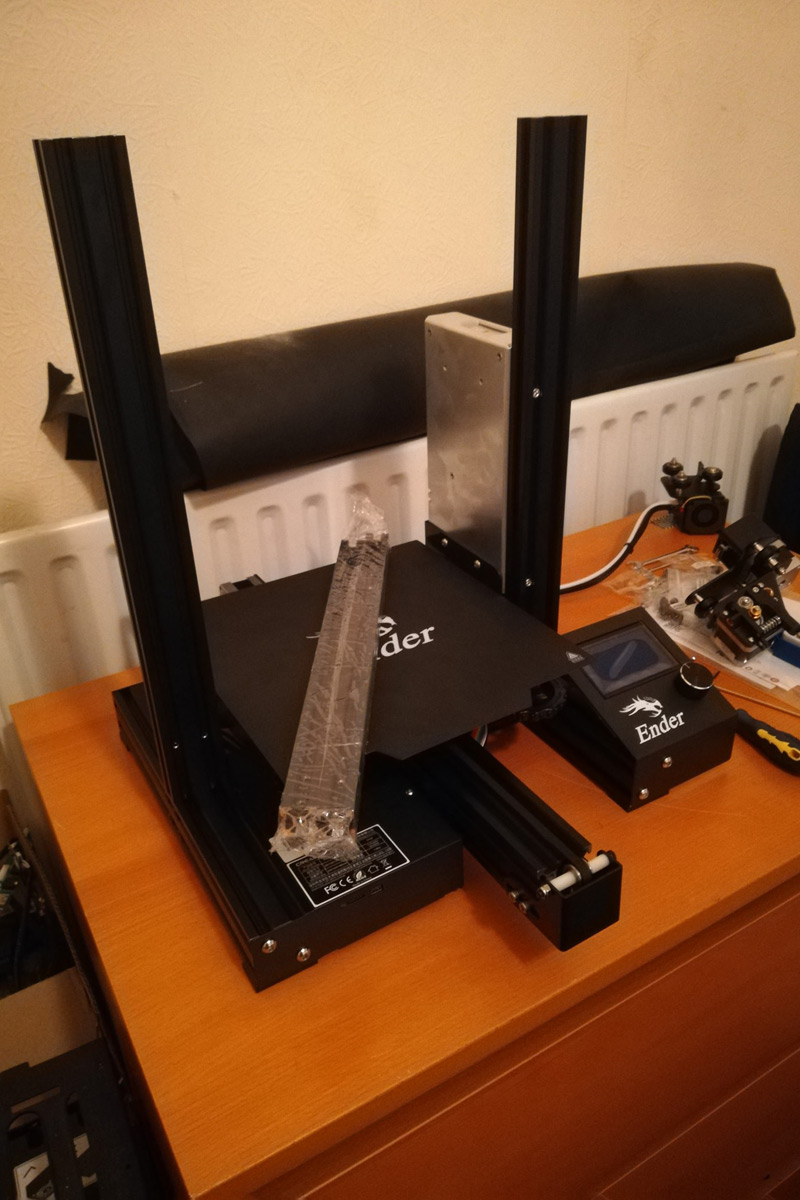

Need to tidy the house first before I carry on, not even soldered up my PCBs yet! Although the 3D printed bits have come out rather well

Need to tidy the house first before I carry on, not even soldered up my PCBs yet! Although the 3D printed bits have come out rather well

Yeah good point. The superglue would be the tiniest flick of a brush just to hold the Paracord in place before melting (Lutro0 does it in his Paracord guide), but even then it won't have anything to melt onto and hold fast. May have to go heatshrink style on my hard drives, not that you can see the SATA power anyway.

Soldato

- Joined

- 28 Dec 2017

- Posts

- 9,287

- Location

- Beds

Superglue makes some unpleasant vapours when heated, don't get them in your eyes!Yeah good point. The superglue would be the tiniest flick of a brush just to hold the Paracord in place before melting (Lutro0 does it in his Paracord guide), but even then it won't have anything to melt onto and hold fast. May have to go heatshrink style on my hard drives, not that you can see the SATA power anyway.

Soldato

- Joined

- 28 Dec 2017

- Posts

- 9,287

- Location

- Beds

Ok, long term damage aside it'll sting like a *****Gotta huff dem fumes! It'll be fine, according to naysayers and fear mongers I should be dead already with the amount of PLA I've been breathing in with my printer

I used to heat guitar frets before removal and theres nothing like a jet of heated cyanoacrylate vapour to the face!