Okay, to keep everyone up to date with how things are looking, I have these few pictures.

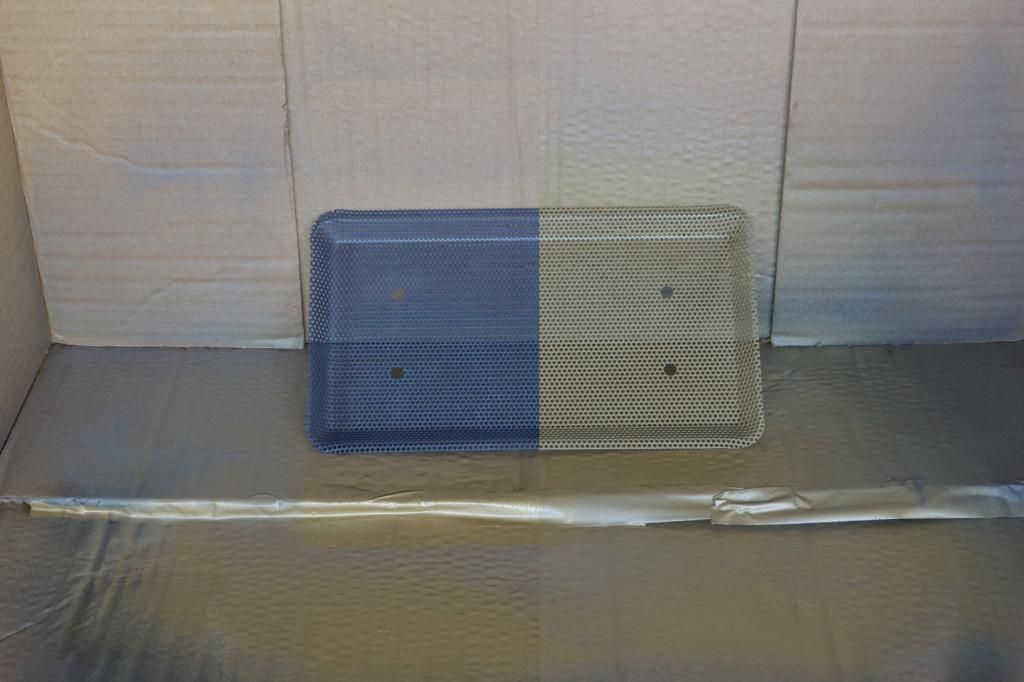

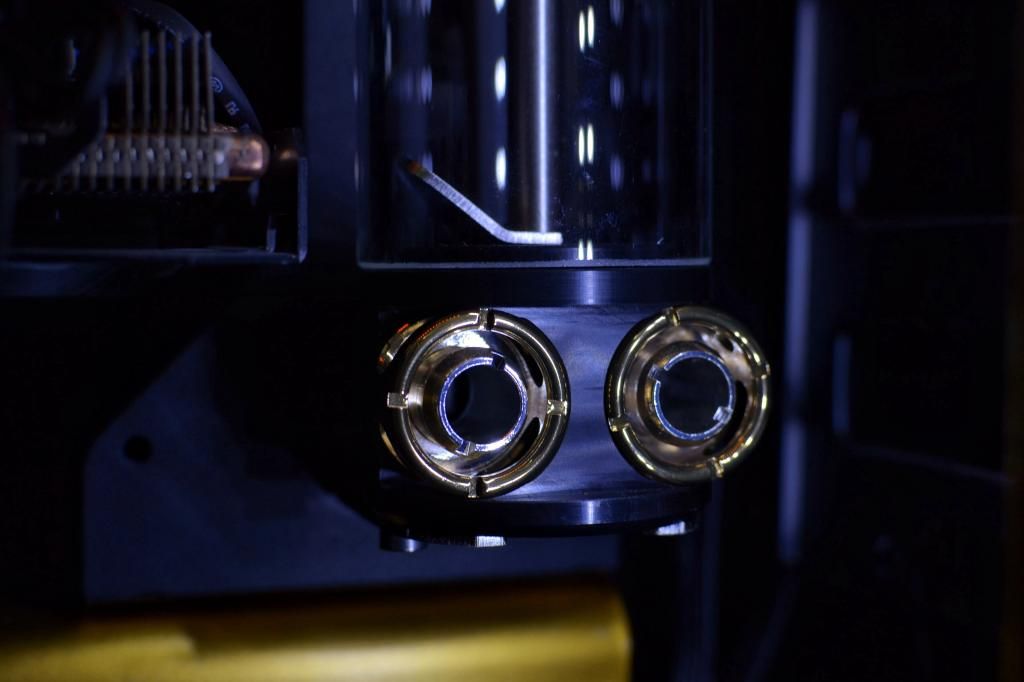

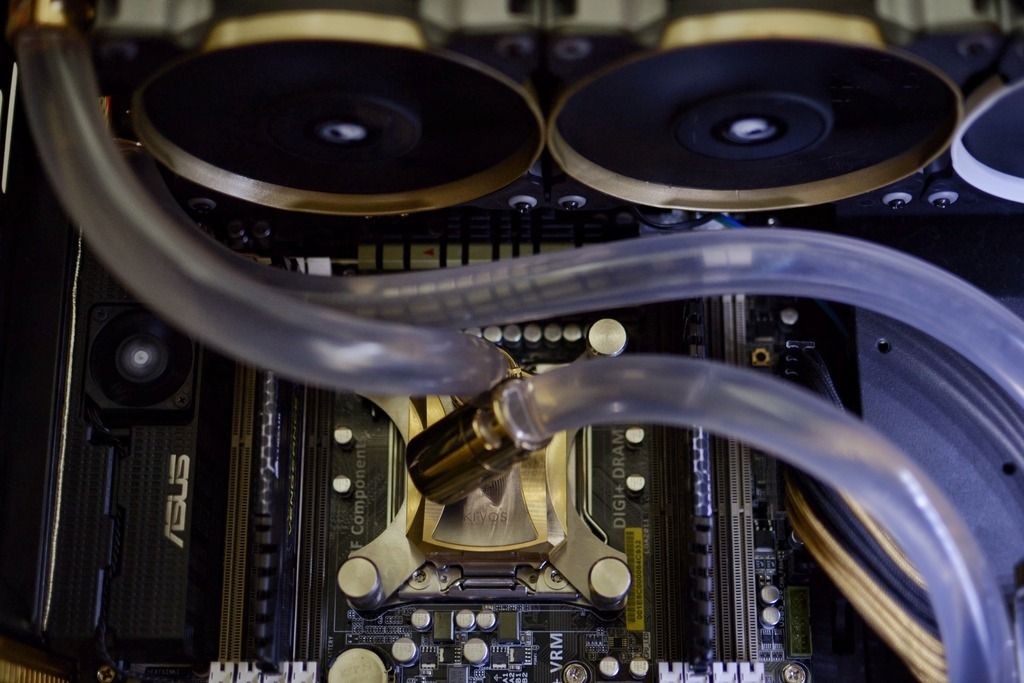

First up is this extremely frustrating incident. The Fittings can't sit next to each other as the inlet & outlet are 1mm too close together. So, a 45 degree rotary is on it's way to hopefully fix the isssue!

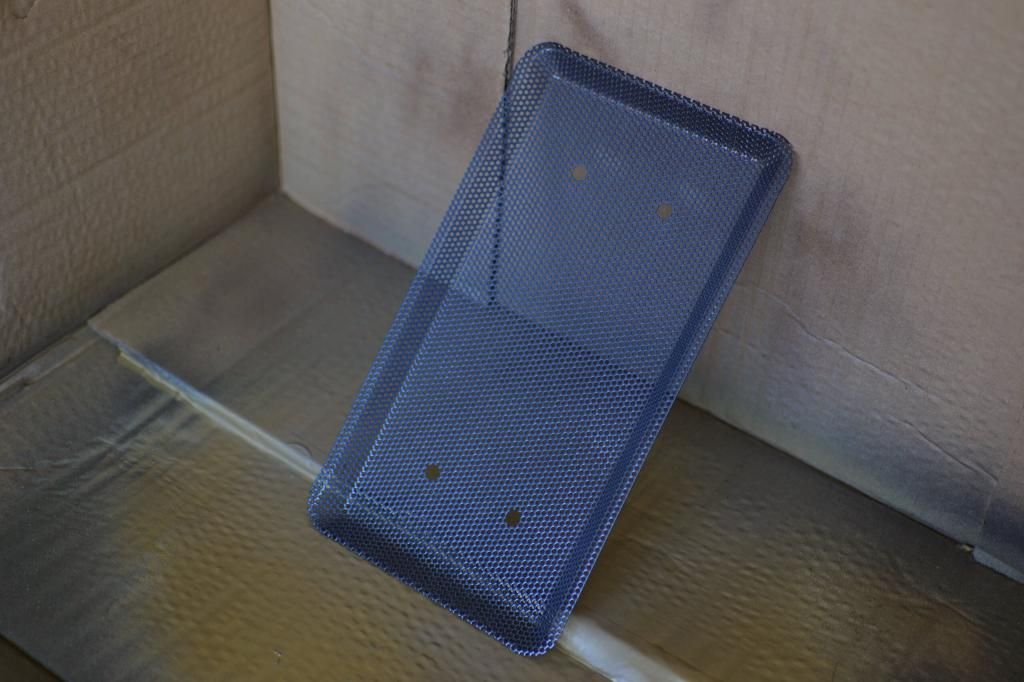

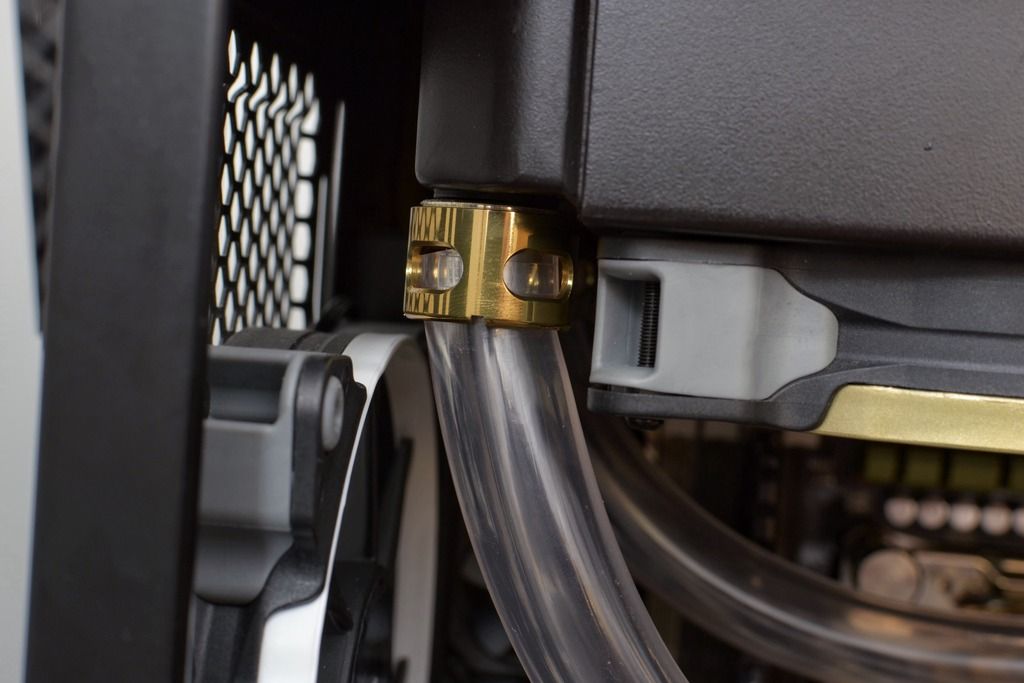

Until the 45 degree rotary arrives, this is how I've secured the tubing for the leak test (which obviously failed majorly!). The zip tie isn't visible when I'm not holding the other tube up, so it's not too bad appearance-wise.

Will this be a problem? It's on the barb just fine, but because of the angle & the length of tubing being so short, it's got a bit of tension pulling the tube like this. Will this leak or should I be okay?

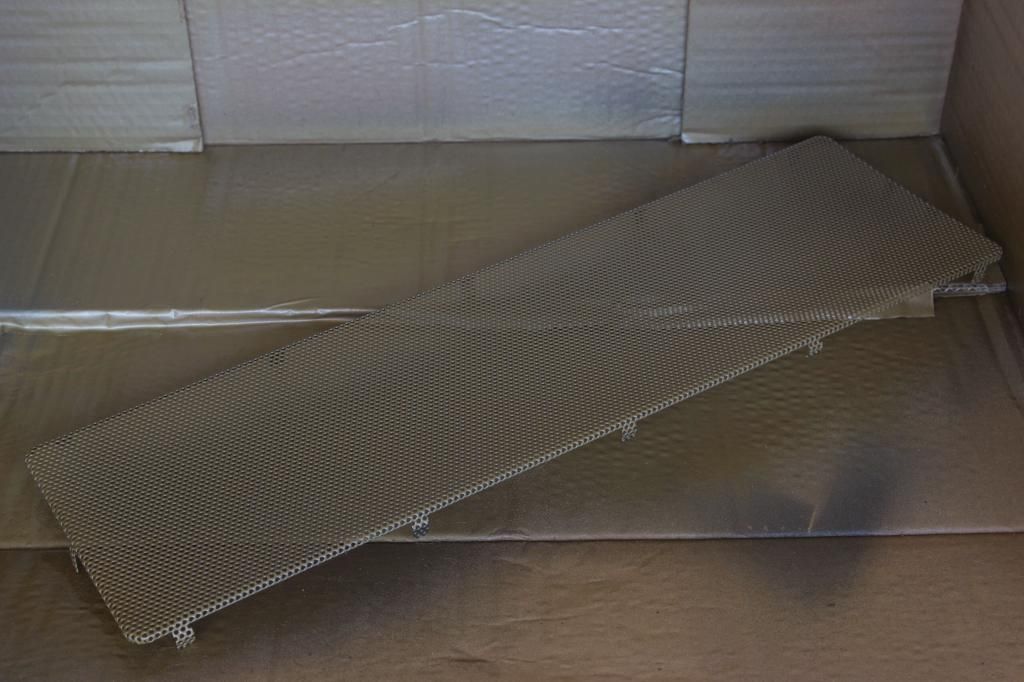

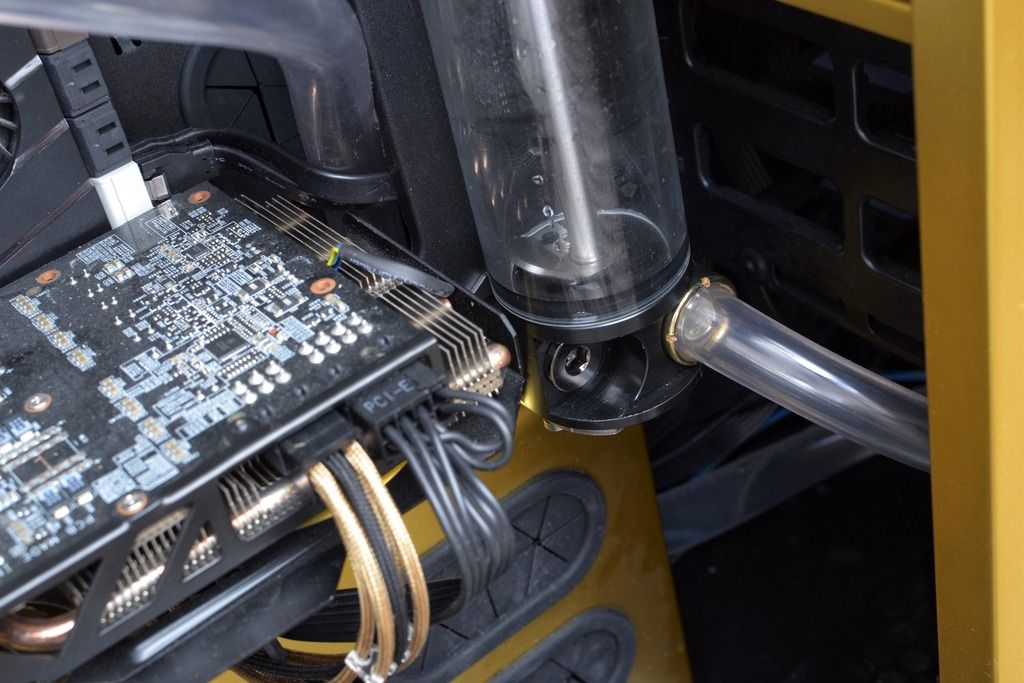

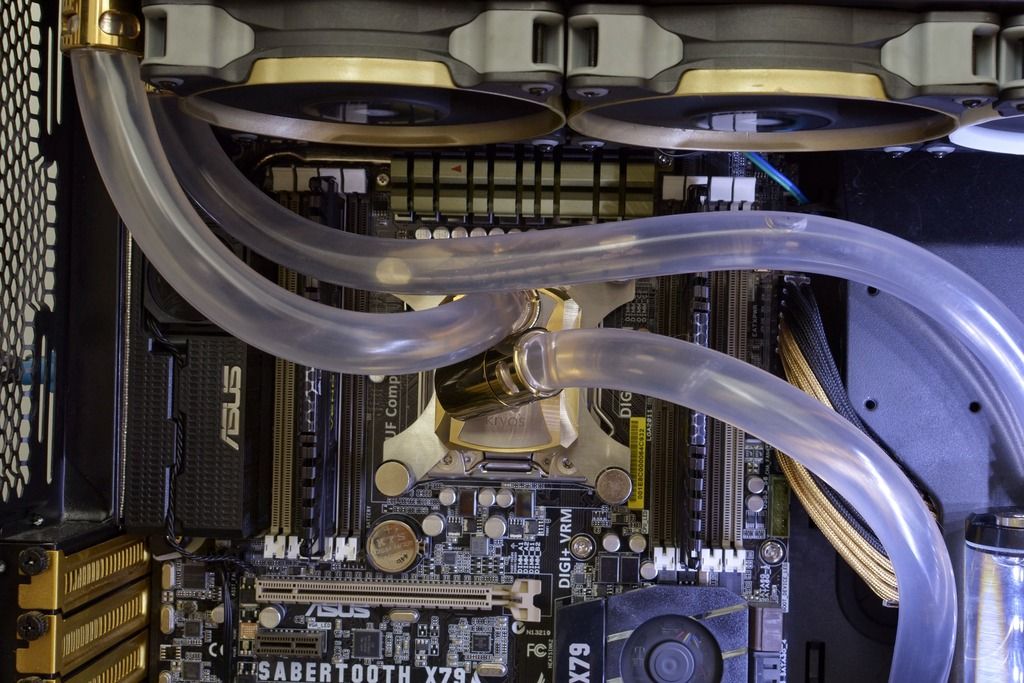

From the res down & round the back as discretely as possible to the pump, then out the pump, straight up behind the res bracket towards the cpu. Wanted to keep the tube routing as clean as possible for this, hence the awkward res - pump route.

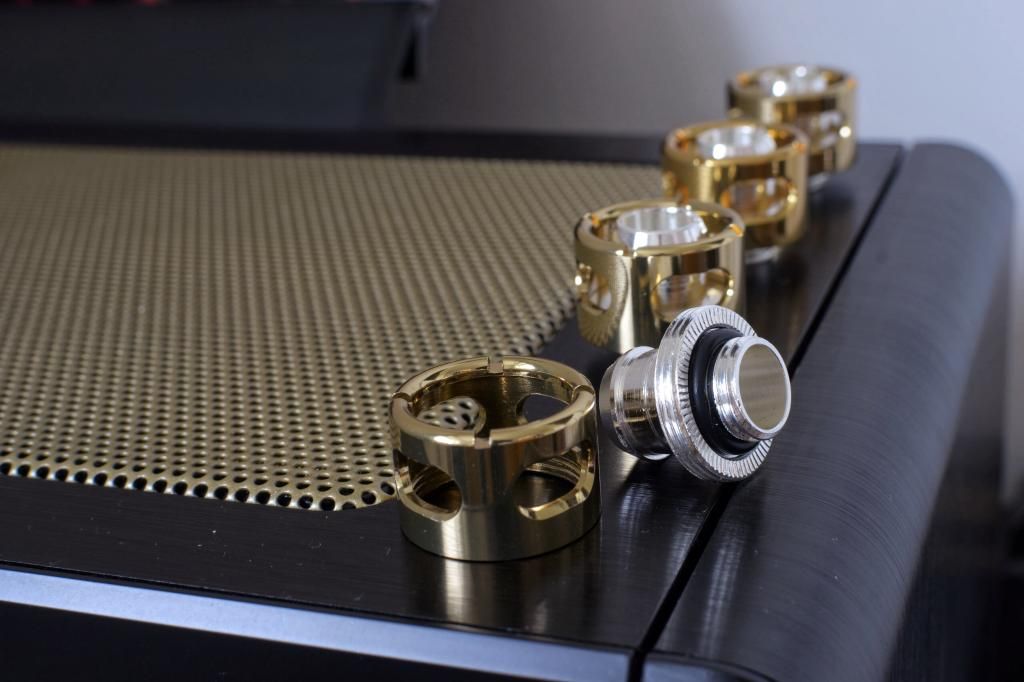

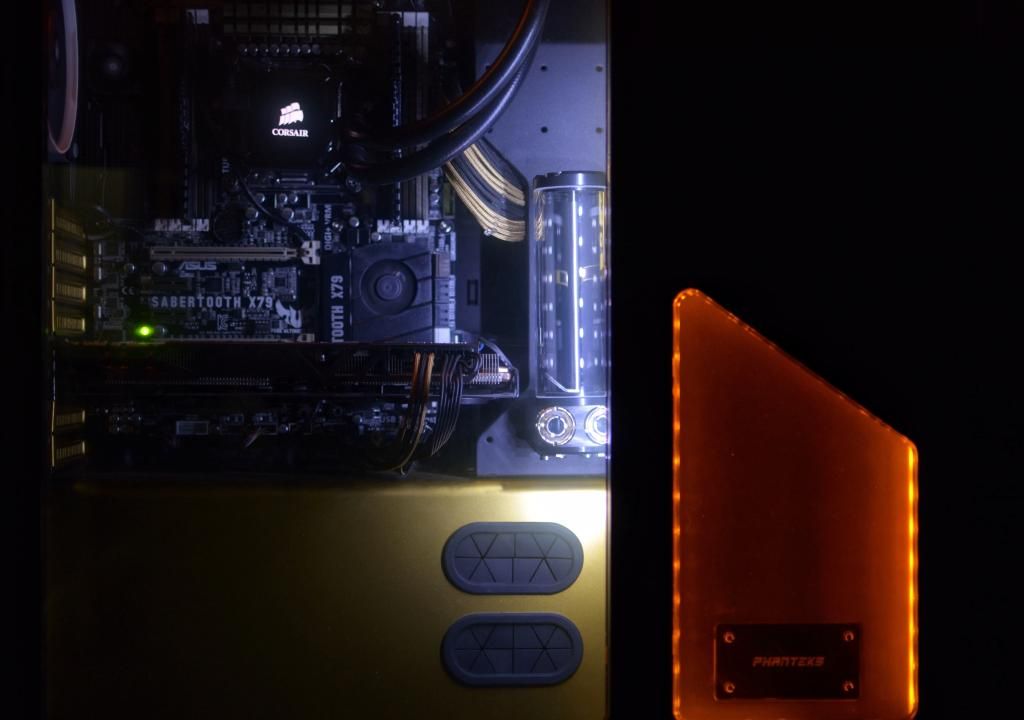

And here's the finished loop. All ready to get filled once the pump O-ring and 45 degree rotary turn up. Quite pleased actually!

Sorry guys & girls!

Sorry guys & girls!

Anyone wanna take a guess who it could be?!

Anyone wanna take a guess who it could be?!