Time for a progress update with some particularly potatoey pictures!

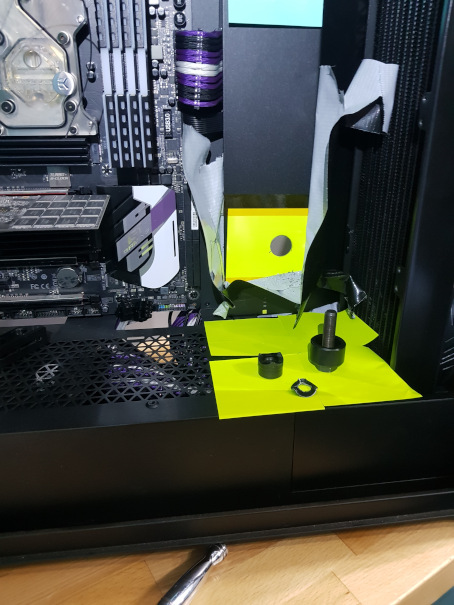

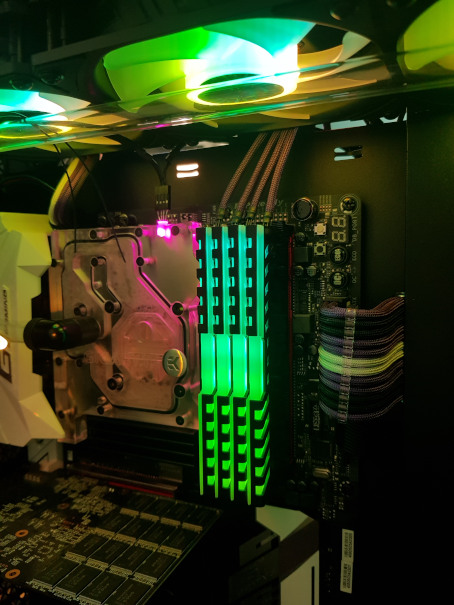

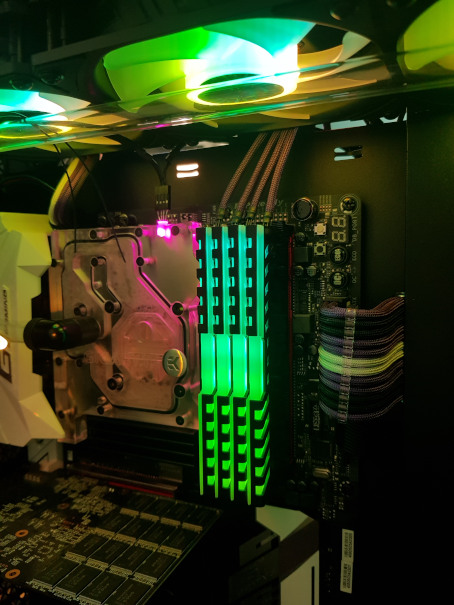

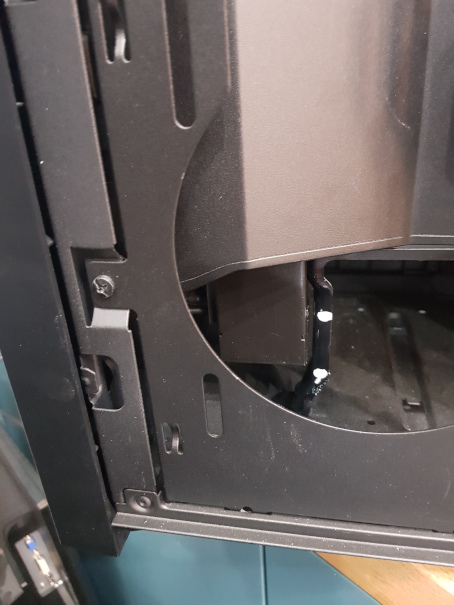

Right, first up we have the pass-through drilled and installed. Piece of tube is just for measuring the bends-to-be. Donor PC has now been stripped so we have the GPU in place with some luverly-looking power leads

It's a good job I remembered to carefully account for the length of that GPU when I was mounting the res or it may only JUST have it! Good job I didn't forget aaaall about it and just centre the res on the backplate behind it!

There's 12mm....but as they say, clearance is clearance

Need to bend a tube from the shroud to the GPU and from GPU to CPU (inlet is hiding behind the dangling LED)...but I'll get to that in a sec.

Under the plastic clip-on bit is the drain. For once in my builds, this is actually at the lowest point!

That tube carries on....

...and after a nice 90° bend (unlike the 88° first attempt

) connects to the outlet of the pump.

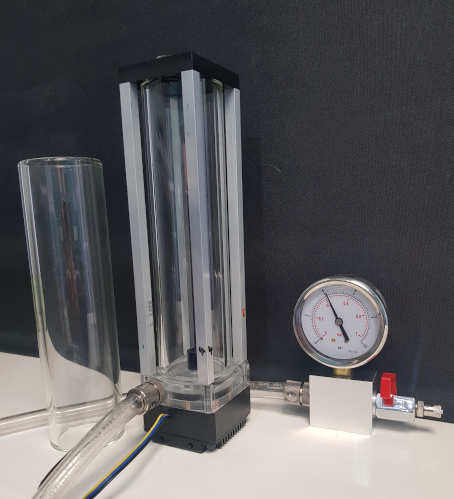

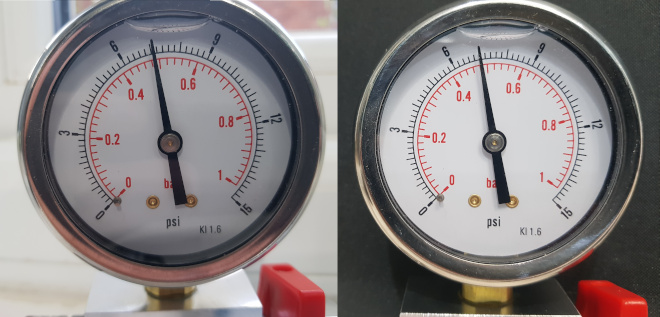

I plugged up the CPU, swapped the res' pressure-relief mebrane for a stop plug and hooked up the pressure tester last night. So far, this is all good. The top joint (the D-plug) where the res hangs from the fittings did spread a little but nowhere near letting go as it's restrained by the bottom fitting. In actual use it won't spread like that as the aforementioned pressure-relief membrane will....er, relieve the pressure.

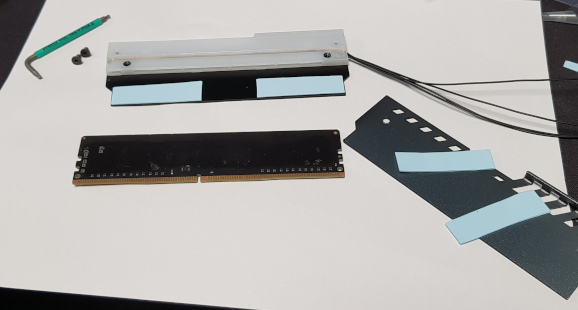

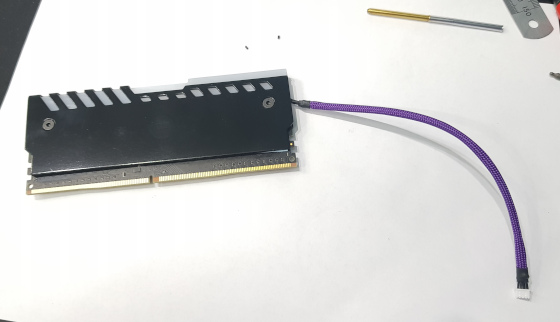

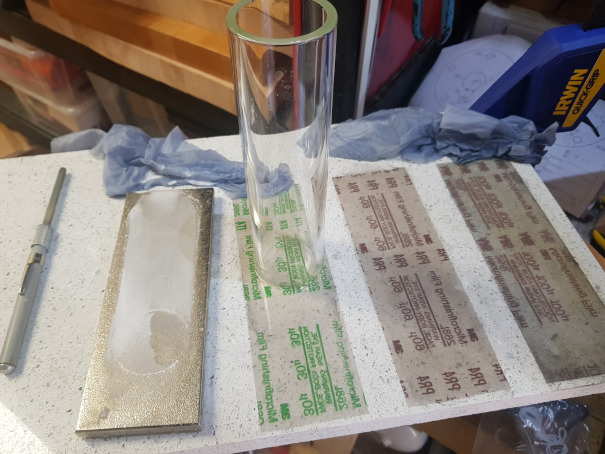

Now, I said I'd get back to the tubes to be bent for the GPU...and there's a reason for that. I decanted my parcel tube of spare tubing and got out the spare 12mm lengths to have a go at making a mess of the next bends. Odd, they don't fit the mandrels....ah, these are 13mm tubes and won't fit the fittings *facepalm* Se we're mostly on hold until OCUK post me some more. You wait, they'll hit the post just in time to get caught in another strike

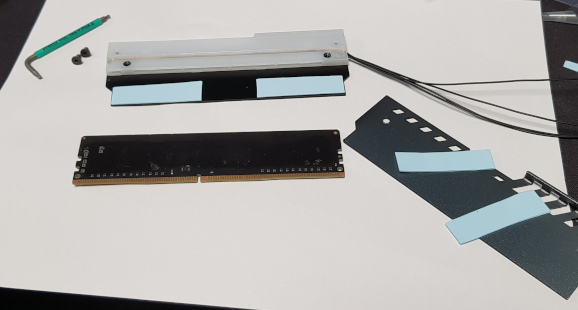

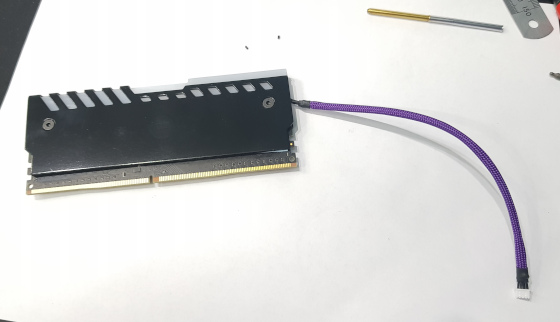

Aquaero is also out of the donor PC, the screen removed (don't need it) and the slightly redesigned mounting plate being printed on the 3D printer. The holes weren't 32mm and 137mm centres, they were 31.5mm and 137.5mm or something like that. Not the round numbers I'd approximated at without removing it from the donor. I also need to allow some countersinking (not enough space behind the plate without it) at the back for the screws to go through from there instead of threaded holes like I'd planned.

So things are moving along...but delayed. You'll know the tubing has arrived when you feel the colourful language flowing in abundance.....as I fail to get the bends in the right place. The run is about 300mm and I've order 4x1000mm lengths....I have THAT much faith in myself

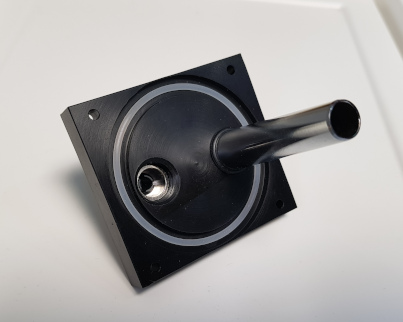

Centre punch, step drill (normal drills tend to make triangular holes in thin metal) to 10mm and then a Q-punch (thing with a bolt through it at the bottom) to take it up to 20.4mm for the 20mm pass-through fitting. Then a spot of deburring to get rid of the sharp edges.

Centre punch, step drill (normal drills tend to make triangular holes in thin metal) to 10mm and then a Q-punch (thing with a bolt through it at the bottom) to take it up to 20.4mm for the 20mm pass-through fitting. Then a spot of deburring to get rid of the sharp edges.