You know the airsoft guns, do you have to get them certified or something that they aren't real weapons/too strong?

the rifles use the mechanics from a airsoft pistol iirc so doubt they will be that powerful

You know the airsoft guns, do you have to get them certified or something that they aren't real weapons/too strong?

the rifles use the mechanics from a airsoft pistol iirc so doubt they will be that powerful

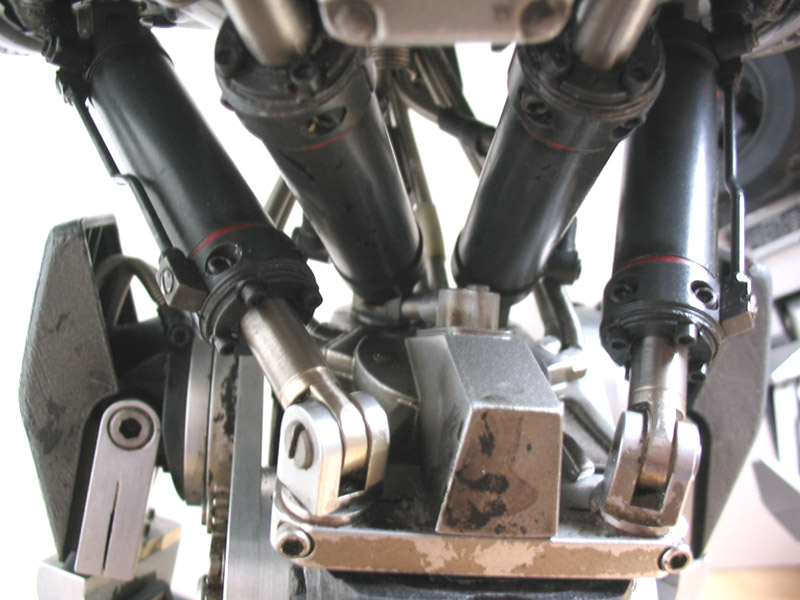

my initial suspisions are realised , after adding the 4 screws there is no material for the 2 verticle screws and it does look

my initial suspisions are realised , after adding the 4 screws there is no material for the 2 verticle screws and it does look

brrrrrrrrrr

brrrrrrrrrr Great skills.

Great skills.

Awesome work there. Are you going to be anodising them black? or painting? Alu is a nightmare to paint if you don't want it to chip off in future.

Anymore updates?