- Joined

- 8 Nov 2006

- Posts

- 1,451

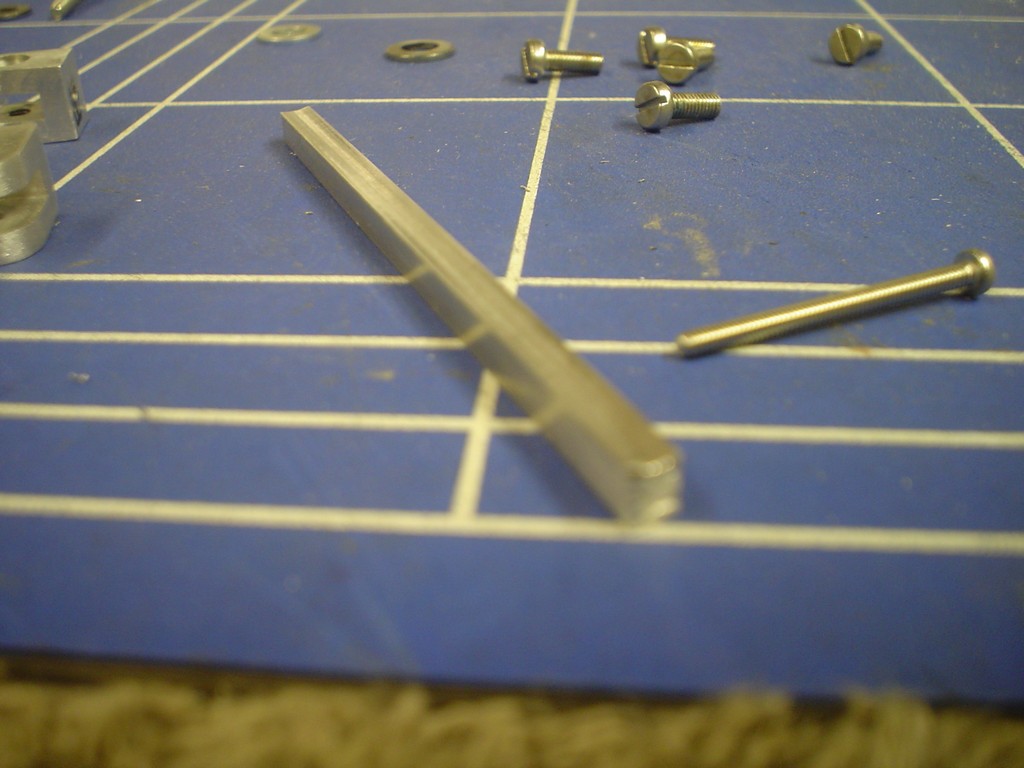

Cut a very thin strip of metal, only 3.5mm across, then had to cut a bevel in the top, did this by wrapping a rod in sandpaper and carefully rubbing away at it.

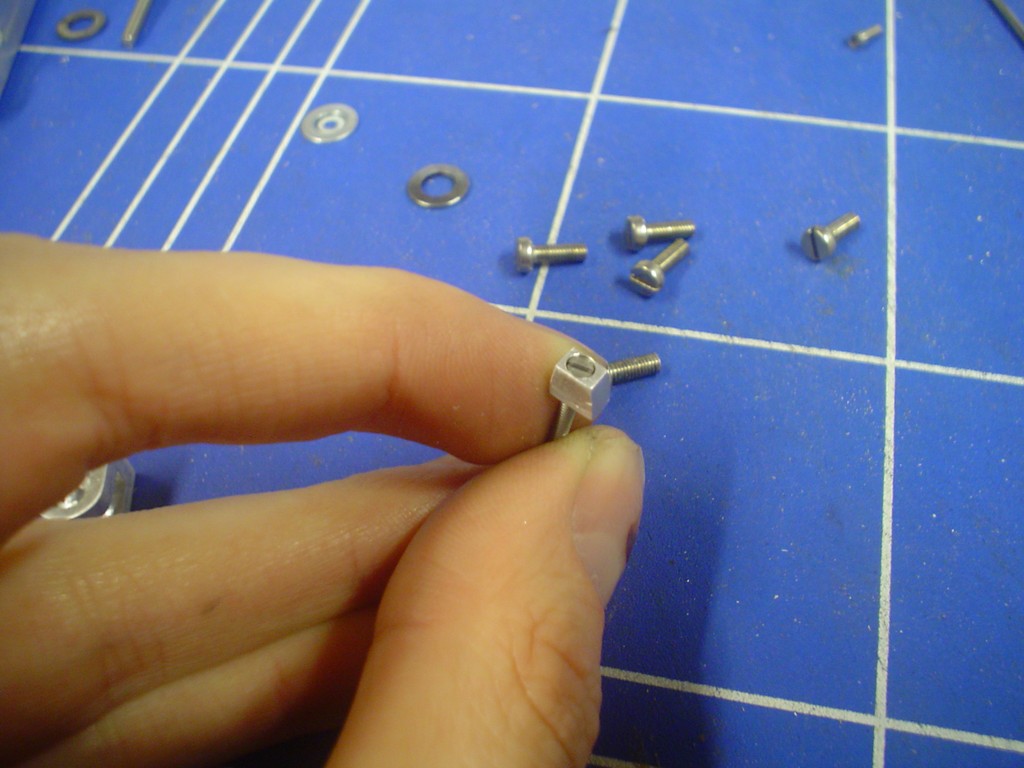

next had to trim 8 of these into this shape then drill them and countersink, no mean feat, I can hardly hold them!

needless to say the M2 flathead screws where a bit too big, so I had to carefully turn all thoses down too.

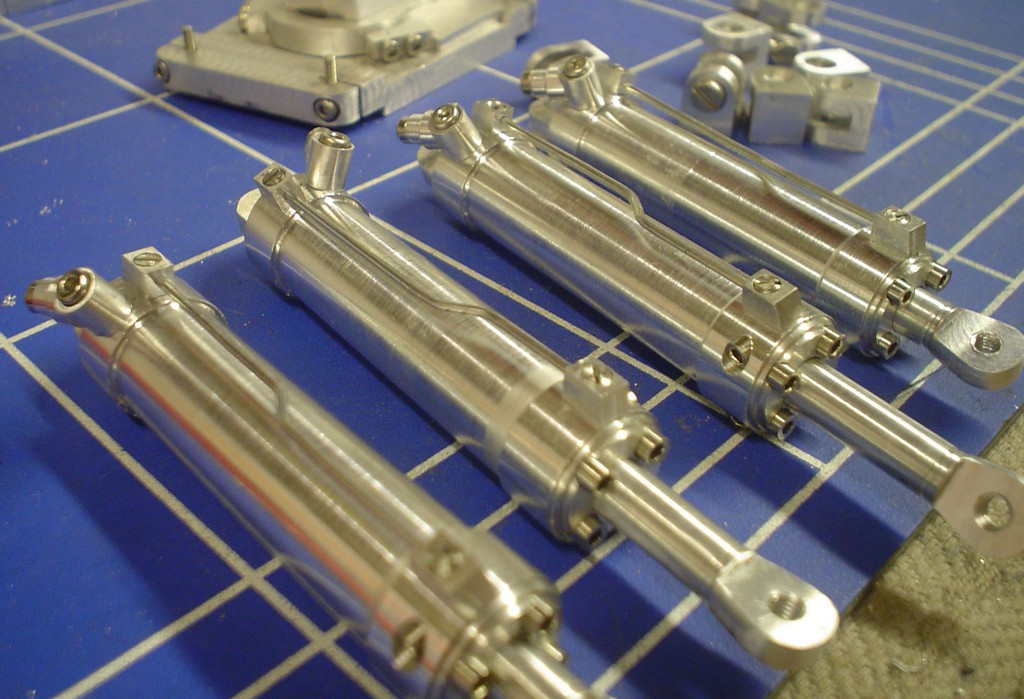

One installed, used a piece of 1.5mm wire for the pipe

and another set of fittings for the pipework

and attached.

Thats pretty much job done on these, im glad I didnt screw anything up

next had to trim 8 of these into this shape then drill them and countersink, no mean feat, I can hardly hold them!

needless to say the M2 flathead screws where a bit too big, so I had to carefully turn all thoses down too.

One installed, used a piece of 1.5mm wire for the pipe

and another set of fittings for the pipework

and attached.

Thats pretty much job done on these, im glad I didnt screw anything up

that's looking AMAZING!!!

that's looking AMAZING!!!